Tracked self-propelled single plant tending machine

A crawler-type, self-propelled technology, which is applied in the direction of land preparation machinery, agricultural machinery and tools, and equipment for eliminating weeds. It can solve the problems of low efficiency and long time consumption, and achieve convenient movement, improved tending efficiency, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

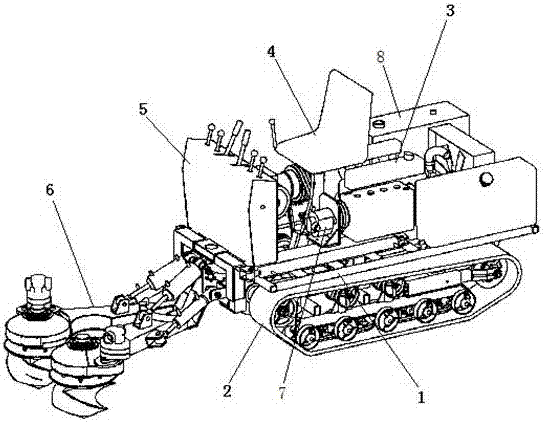

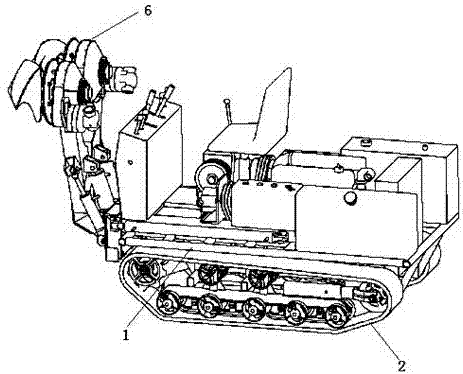

[0036] Attached below Figure 1 to Figure 12 The embodiments of the present invention will be described in detail.

[0037] A crawler-type self-propelled single plant tending machine, including a chassis frame 1, a crawler-type self-propelled mechanism 2 is installed under the chassis frame 1, and a diesel power system 3, a driver's seat 4, and a console 5 are installed above the chassis frame 1. , The hydraulic oil pump 7 connected to the diesel power system and the hydraulic oil tank 8 for the hydraulic oil pump 7, the diesel power system 3 drives the crawler-type self-propelled mechanism 2 to move on the ground, and the mobile operating handle of the crawler-type self-propelled mechanism 2 is installed On the operating table 5, the front end of the chassis frame 1 is equipped with a single plant tending work head 6;

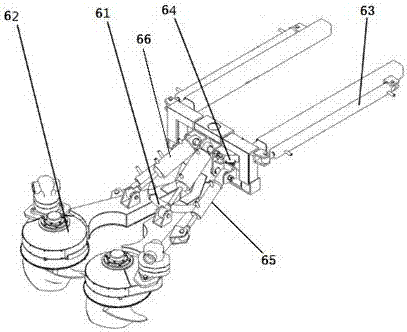

[0038] The single plant tending work head 6 includes a combined working arm 61, a combined working tool 62, a telescopic frame 63 for pushing the combined working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com