Integrated system for green tea sorting and de-enzyming

A sorting and greening technology, applied in the direction of pre-extraction tea treatment, etc., can solve problems such as affecting tea quality and health care efficacy, unable to realize automatic screening, changing monomer ratio, etc., to improve integration, save fuel, reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

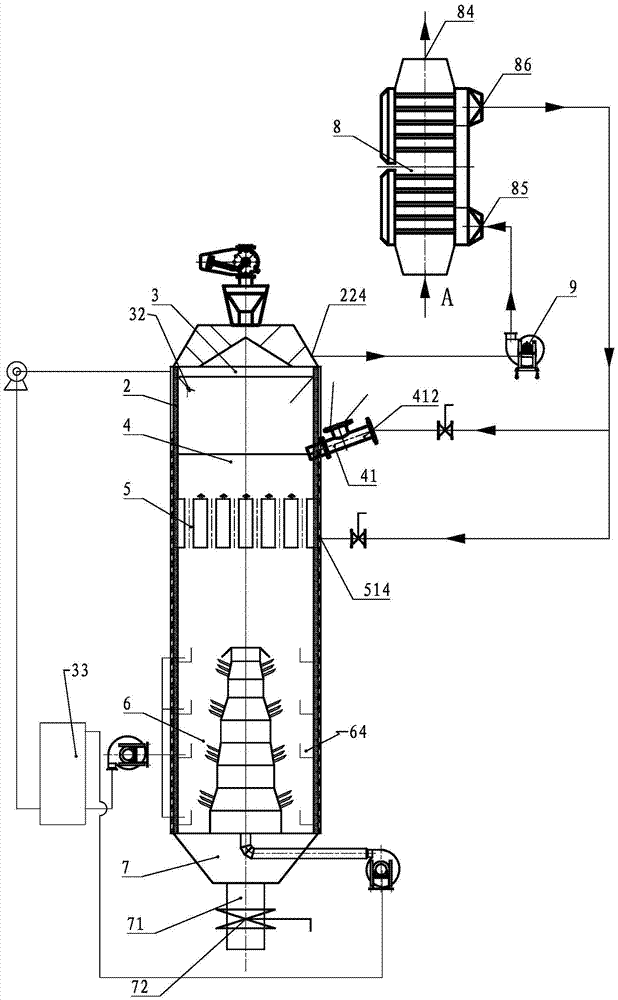

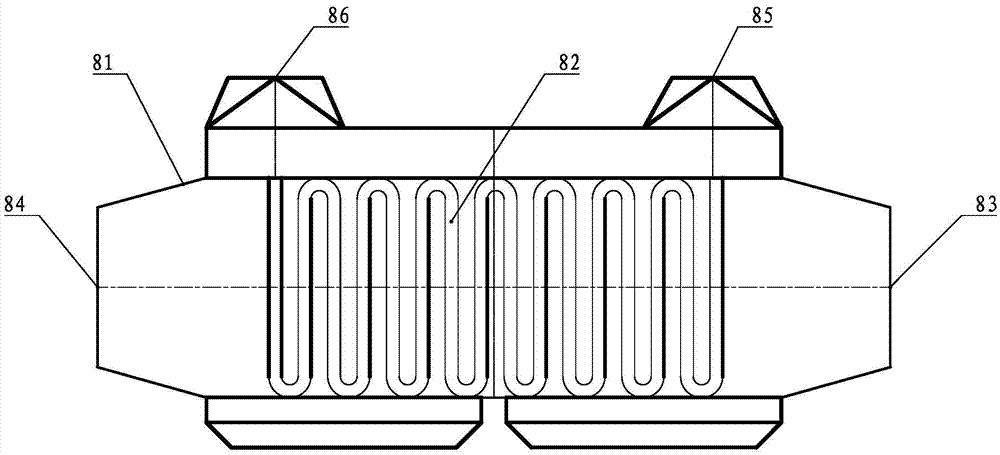

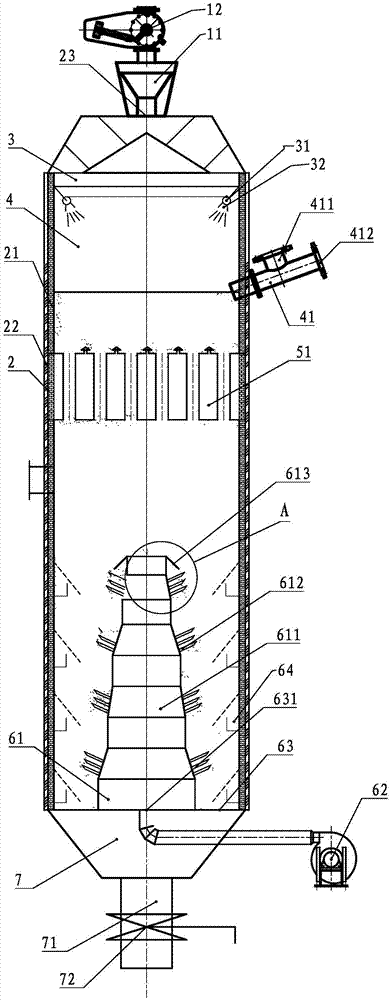

[0045] like Figure 1 to Figure 12As shown, an integrated system for sorting and fixing green tea includes a heat exchange unit and a fixing and sorting tower.

[0046] like image 3 As shown, the fixing and sorting tower includes a tower body 2, and the tower body 2 is sequentially provided with a cleaning chamber 3, a fixing chamber 4, a primary heat exchange chamber 5, a secondary heat exchange chamber 6 and a sewage chamber from top to bottom. Object Pool 7. The tower body 2 is a cylindrical structure with two conical ends and a cylinder in the middle, and the inner and outer parts of the cylindrical part in the middle are respectively provided with an inner insulation layer 21 and an outer insulation layer 22. The materials of the inner heat preservation layer 21 and the outer heat preservation layer 22 are heat preservation and refractory materials, and the fireproof performance is Class A.

[0047] The tower body is provided with an observation window that can observ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com