Gas processing equipment and method

A gas treatment and equipment technology, applied in the field of gas treatment equipment, can solve the problems of inability to pulverize viscous particles, secondary pollution, and high treatment costs, and achieve the effects of long service life, high purification efficiency, and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

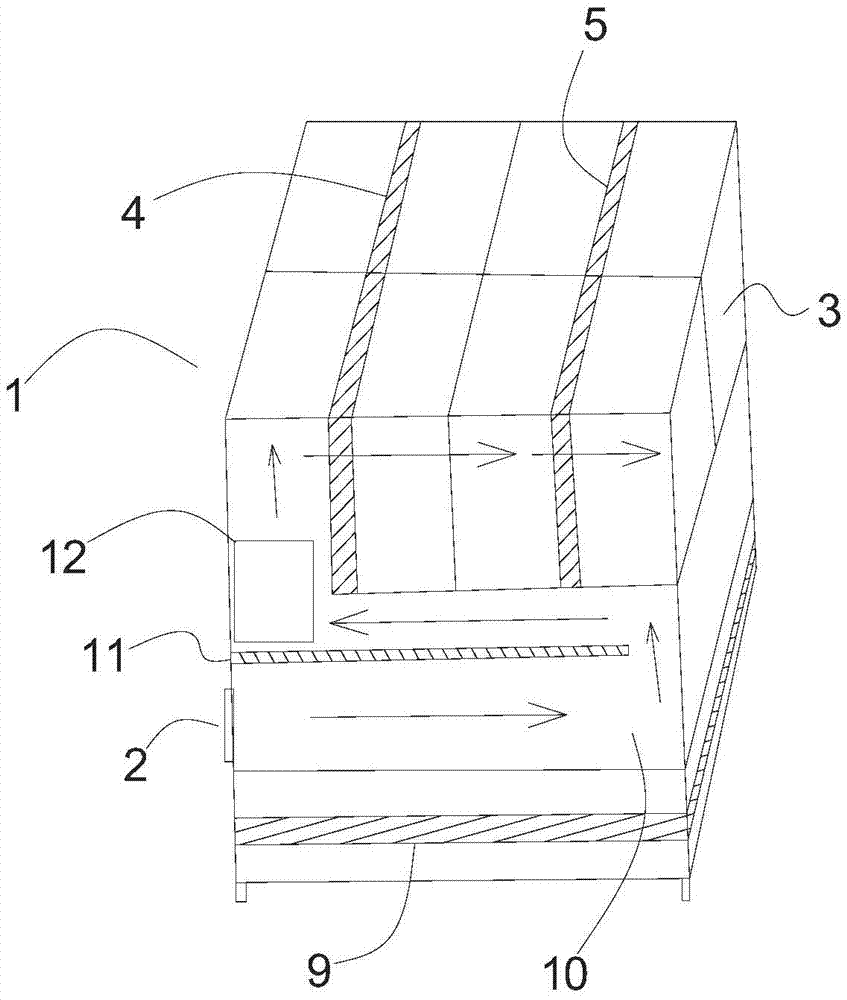

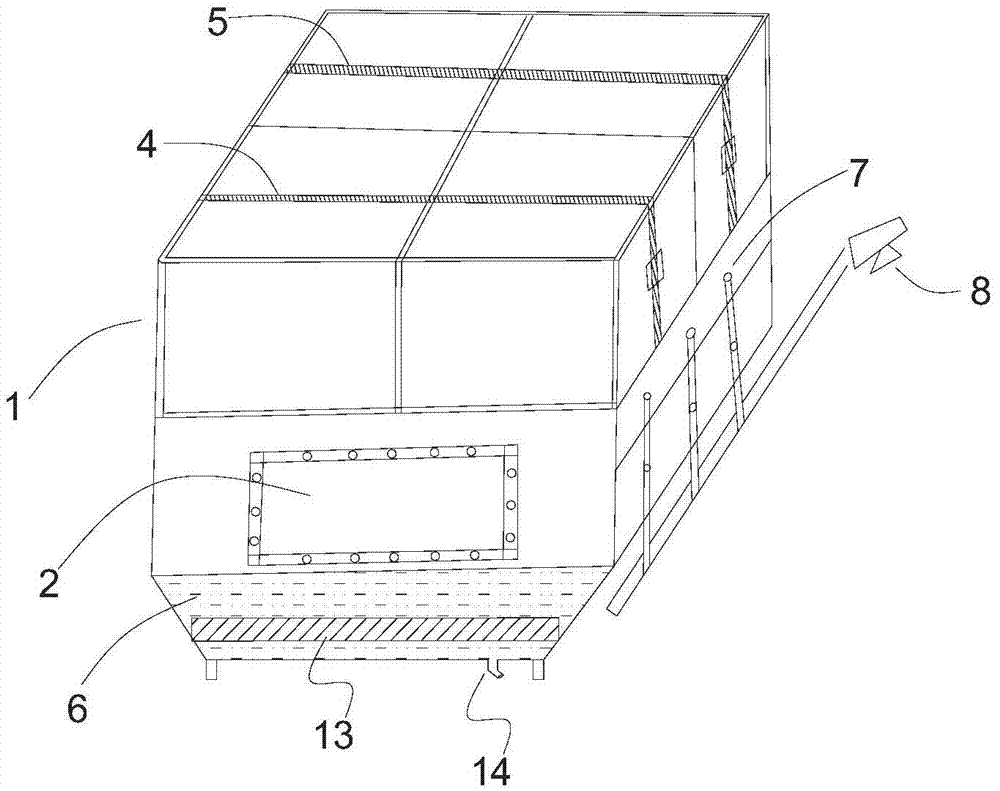

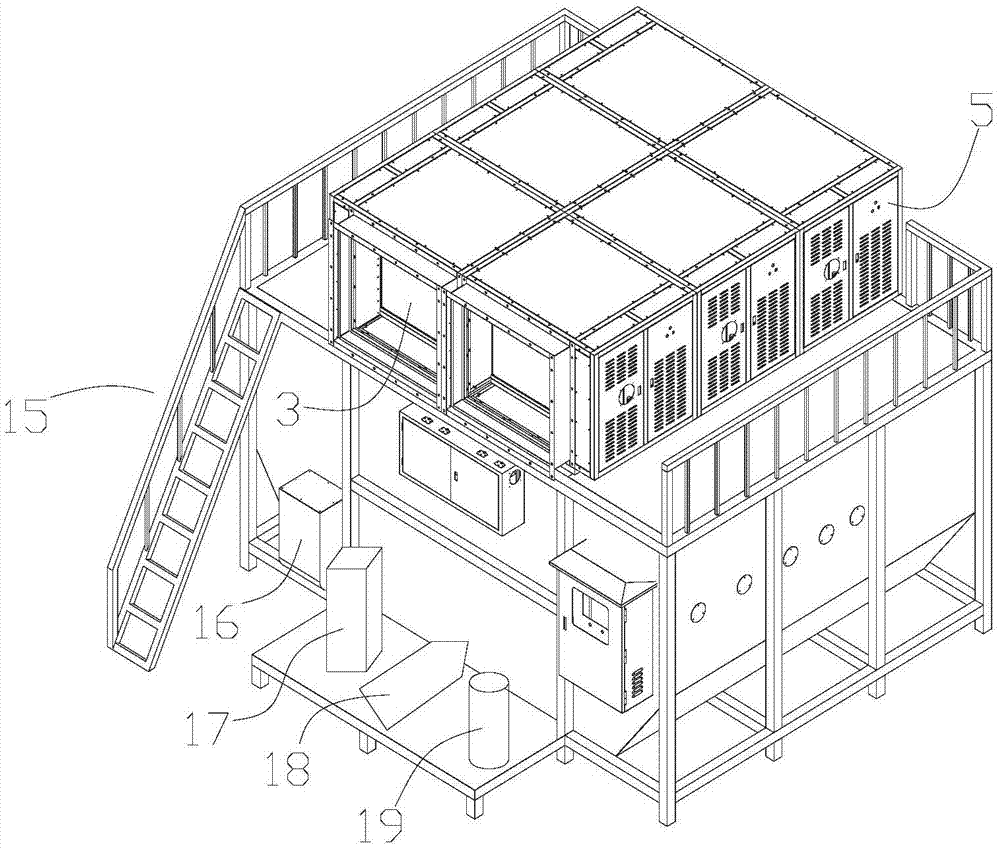

[0022] like Figures 1 to 4 As shown, a gas processing device includes a housing 1 with a gas flow channel 10 inside, an air inlet 2 for the gas flow channel 10 is opened on one side wall of the housing 1, and the other side of the housing 1 The gas outlet 3 of the gas flow channel 10 is opened on the side wall, and the water 6 is stored in the housing 1 below the gas flow channel 10, and ultrafine bubbles of ozone are introduced into the water, and an oxidation catalytic layer is provided under the water surface 9. Along the path of gas flow, a sprayer is provided above the first half of the gas flow channel 10, and a catalytic oxidation filler 12 and a demister module are sequentially installed in the second half of the gas flow channel 10 against the air flow 4 and the infinite ultraviolet photolysis module 5.

[0023] Wherein, ozone is produced by ozone generator 17, and the outlet of this ozone generator 17 is connected with the bubble pump 18, molecular stack 19 and foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com