A kind of preparation method of platinum-rhenium reforming catalyst and platinum-rhenium reforming catalyst

A reforming catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, naphtha catalytic reforming, etc., can solve problems such as prolonged start-up time, catalyst poisons, reaction equipment corrosion, etc., and achieve economical start-up The effect of time, simple production process and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a platinum-rhenium reforming catalyst, the method comprising the following steps:

[0024] (1) The sodium alkyl xanthate solution with a pH of 7.5-9 is contacted with an alumina carrier, and after filtering and drying, a dry sample is obtained;

[0025] (2) contacting the dried sample with the first active component solution, drying and roasting to obtain the catalyst intermediate;

[0026] (3) contacting the catalyst intermediate with the second active component solution, then drying and roasting;

[0027] Wherein, the first active component solution contains a platinum-containing compound and a rhenium-containing compound, and the second active component solution contains hydrochloric acid,

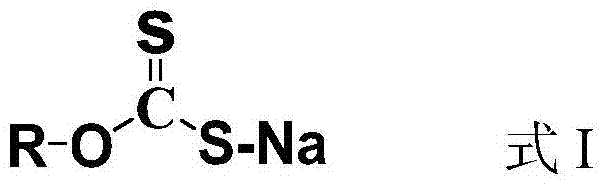

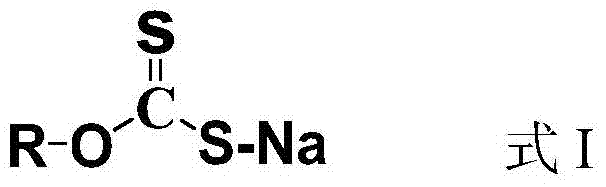

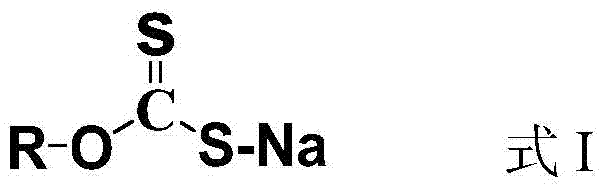

[0028] The structure of the sodium alkylxanthate is shown in formula I,

[0029]

[0030] In formula I, R is C 2 -C 4 straight-chain or branched-chain alkyl groups.

[0031] In the present invention, the alumina support may be...

Embodiment approach

[0050] The amount of active components platinum and rhenium can be selected according to the needs of the reforming catalyst. According to one embodiment of the present invention, the content of platinum in the first active component solution may be 0.05-1% by weight, preferably 0.1-0.5% by weight; the content of rhenium may be 0.05-1% by weight. %, preferably 0.1-0.7% by weight.

[0051] In step (2), the contacting method can be the same as that in step (1), that is, at a temperature of 15-40° C., soak or spray the dried sample with the first active component solution. . In order to further uniformly disperse the metal elements platinum and rhenium on the dry sample, the contacting process preferably includes: spraying the dry sample with the first active component solution.

[0052] In step (2), the drying and roasting methods can be carried out with reference to the prior art. Generally, the drying temperature may be 105-120° C., and the time may be 4-8 hours; the roasti...

preparation example 1-4

[0067] Preparation examples 1-4 are used to illustrate the preparation methods of the first active component solution, the sodium alkylsulfonate solution and the second active component solution of the present invention, that is, various dipping solutions.

[0068] Sodium alkyl xanthate solution: Dissolve the sodium alkyl xanthate in 50 g of deionized water to prepare a solution with a certain concentration, then adjust the pH with 23% by weight of ammonia water.

[0069] The first active component solution: dissolving chloroplatinic acid and perrhenic acid in 50 g of deionized water to prepare an impregnating solution containing metal elements platinum and rhenium.

[0070] The second active component solution: dilute hydrochloric acid (36.5% by weight) with 50 g of deionized water to prepare an impregnating solution containing elemental chlorine.

[0071] The content of each main component in the above impregnating liquids, the sodium alkylxanthate used and the pH value of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com