Digital manufacturing method for bucket tooth of excavator for mine

A technology for excavator bucket teeth and manufacturing methods, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of consuming a lot of time and money, and low precision of the original blank, so as to reduce labor intensity and facilitate the molding method , Improve the effect of product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

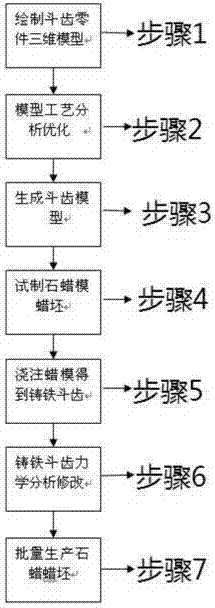

[0020] like figure 1 . As shown in the mold-making flow chart, a digital manufacturing method for mining excavator bucket teeth of the present invention includes the following steps:

[0021] 1) Draw the bucket tooth parts diagram, and use CAD software to build a three-dimensional bucket tooth solid model;

[0022] 2) Use the casting simulation software to simulate the analysis and optimization of the casting process.

[0023] 3) Generate the model part of the bucket tooth casting mold.

[0024] 4) Trial production of bucket tooth paraffin mold wax blank.

[0025] 5) Casting a trial-produced paraffin wax blank to obtain a cast iron bucket tooth blank.

[0026] 6) The mechanical test of the cast iron bucket tooth blank and the modification of the parameters of the paraffin mold wax blank are carried out.

[0027] 7) Mass production of paraffin mold wax blanks.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com