Method for controlling formation of foreign crystals at variable cross section

A technology of variable cross-section and miscellaneous crystals, applied in the field of superalloy microstructure and solidification, can solve the problems of reducing the mechanical properties of superalloys, limited effect of miscellaneous crystal suppression, low production efficiency, etc. The effect of miscellaneous crystal formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

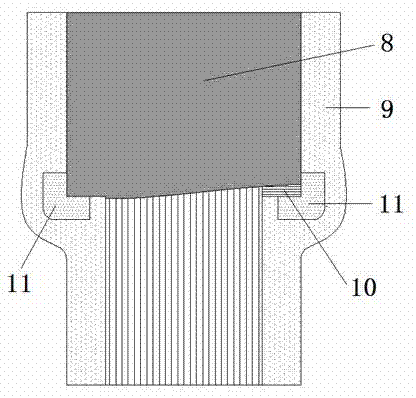

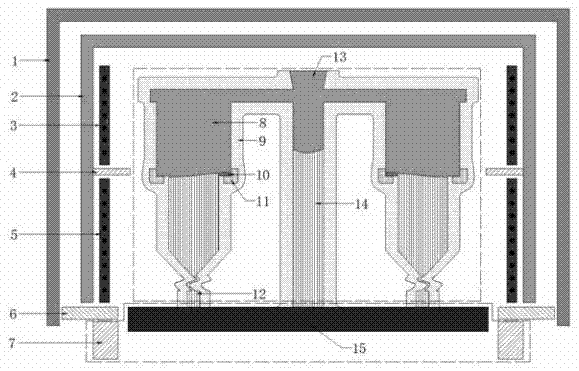

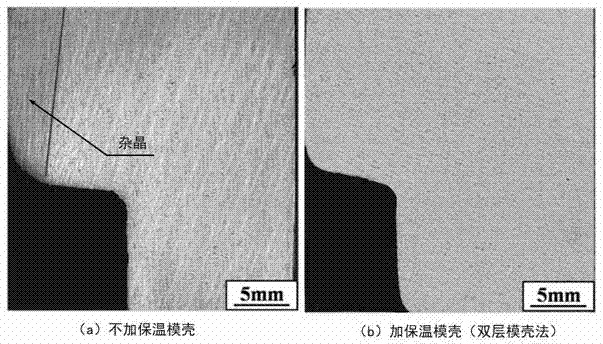

[0022] In this example, see Figure 1~3, a method for controlling the formation of miscellaneous crystals at variable cross-sections is implemented by using a device for controlling the formation of miscellaneous crystals at variable cross-sections. The device for controlling the formation of miscellaneous crystals at variable cross-sections includes a furnace body 1 and a heater 2. There is a fixed radiation baffle 6, which divides the inner cavity of the entire furnace body 1 into an upper heating zone and a lower cooling zone, and the casting system is pulled from the heating zone to the cooling zone so that the molten metal is processed from bottom to top. The directional solidification of the casting system includes the casting cavity base formwork 9, the spiral crystal selector 12 and the sprue 13 on the top of the formwork, and the casting cavity base formwork 9 forms a cylindrical casting cavity with vertically segmented and variable cross-sections. The liquid superall...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, especially in that:

[0031] In this example, the device for controlling the formation of miscellaneous crystals at the variable section in Example 1 is used to carry out directional solidification of variable section castings, increasing the size of the variable section to 15 mm, and the samples are variable section with lengths of 30 mm and 60 mm respectively. For castings, the temperature of the heater is 1500°C, the initial temperature of the water cooling ring 7 and the bottom water cooling plate 15 is 25°C, and the water cooling is continued, the initial temperature of the mold shell is 1500°C, the thickness of the mold shell is 6mm, and the initial temperature of the alloy melt is 1500°C , after pouring is completed, keep warm for a period of time until the temperature is basically constant, slowly pull the casting system and the bottom water-cooled plate 15 from the heating zone to the cooling zone at a pulli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com