A clamping device in the process of standard sample processing

A technology of processing process and holding device, which is applied in the fields of coal mining and core standard sample processing, can solve the problems of core processing that cannot be less than 75mm, and achieves less manpower and material resources, light weight and good dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

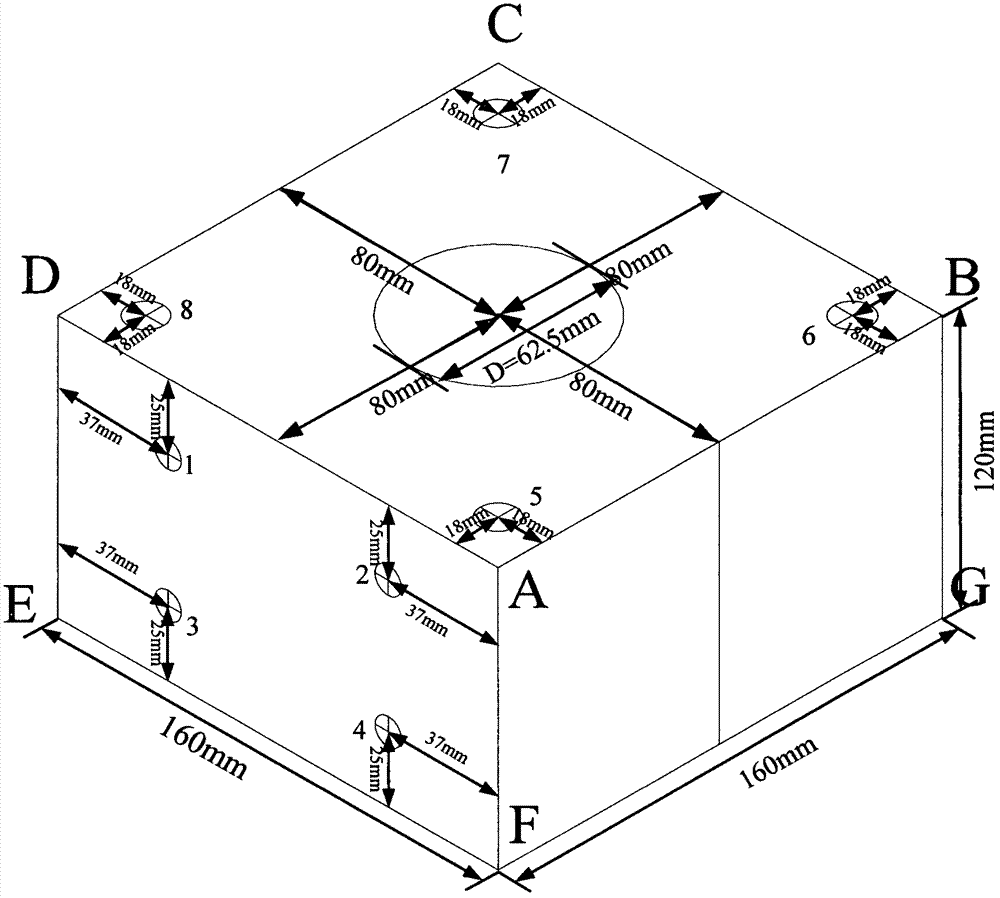

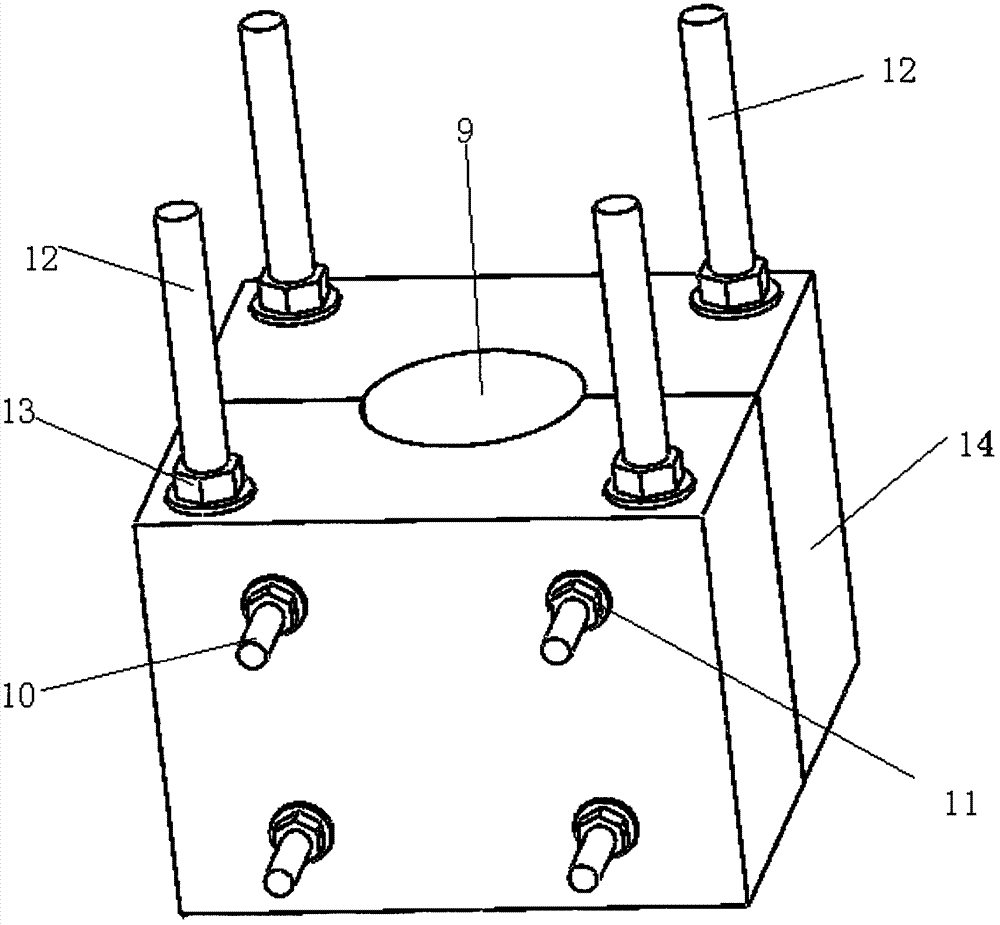

[0034] Such as Figure 1-2 As shown, the present invention provides a kind of clamping device in the standard sample processing process, and it comprises screw rod, nut and fixing device 14, and described screw rod and nut altogether eight sets, wherein, the diameter of four sets of described screw rod and nut is 12mm, and the diameter of the other four sets is 16mm. The fixing device is a cuboid structure processed by a cylindrical nylon rod. The fixing device made in this way has good toughness, strong wear resistance, oil resistance, shock resistance, stretching, Good bending strength, low water absorption, good dimensional stability, etc., a cylindrical hole 9 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com