Full-automatic water bucket bagging machine

A bagging machine, fully automatic technology, applied in the directions of external support, transportation and packaging, single objects, etc., can solve the problems of high labor cost, high labor intensity, easy damage of packaging bags, etc., and achieve strong practical value and market promotion value. Realize the effect of automation and intelligent control and packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

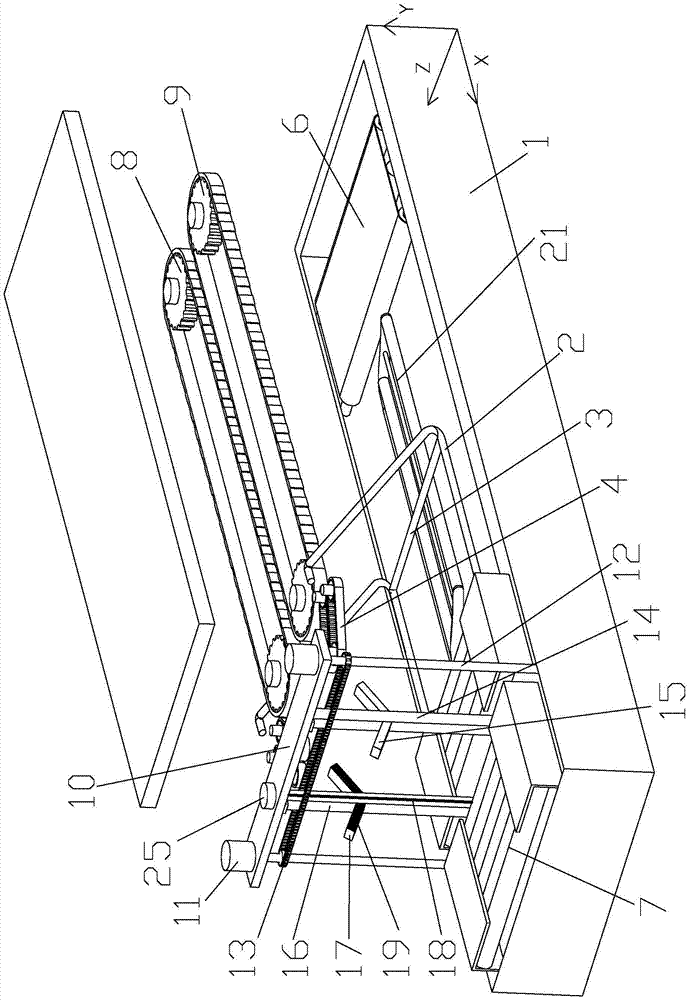

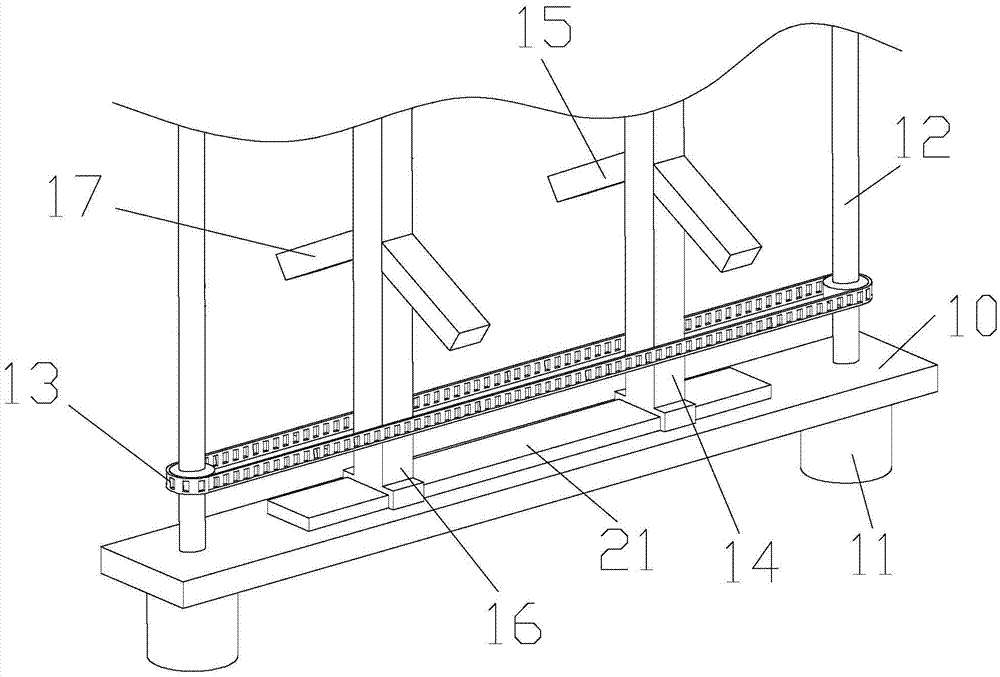

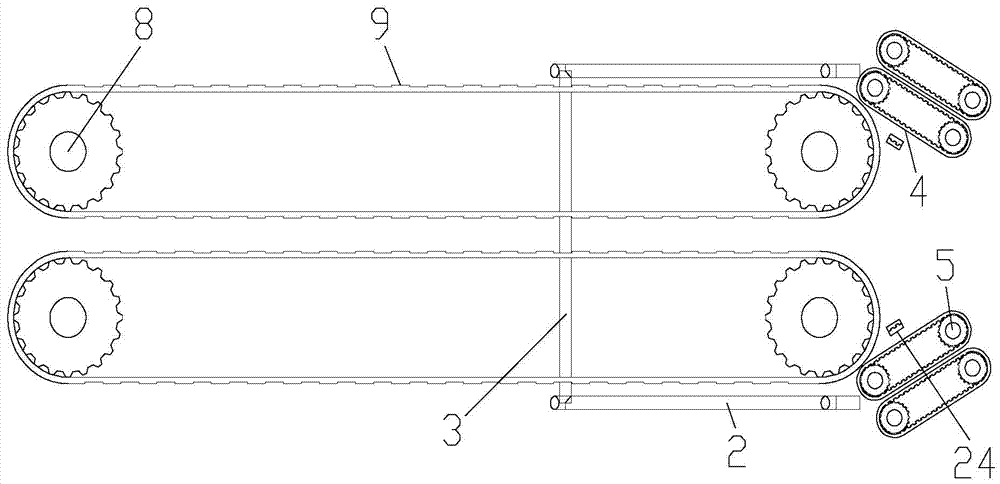

[0032] Such as Figure 1 to Figure 5 As shown, a kind of automatic bucket bagging machine that the embodiment of the present invention provides, it comprises:

[0033] The frame body 1 (which can be actually set according to the layout of the entire equipment) mainly plays the role of positioning and assembling each component mechanism;

[0034] The bucket truss is mainly used to clamp the neck of the bucket and drive the bucket to move along the X-axis direction, and it is installed inside the upper part of the frame body 1;

[0035] Send bag roller group (it is mainly made of several guide film rollers 21 and driving motor (not shown in the figure)), is mainly used for installing packaging bag film roller and conveys packaging bag film in frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com