Nitrogen non-circulating heating device for partial oxidation system

An oxidation system and heating device technology, applied in the preparation of organic compounds, inorganic chemistry, organic chemistry, etc., can solve the problems of energy waste and output reduction, and achieve the effects of increasing output, eliminating waste, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

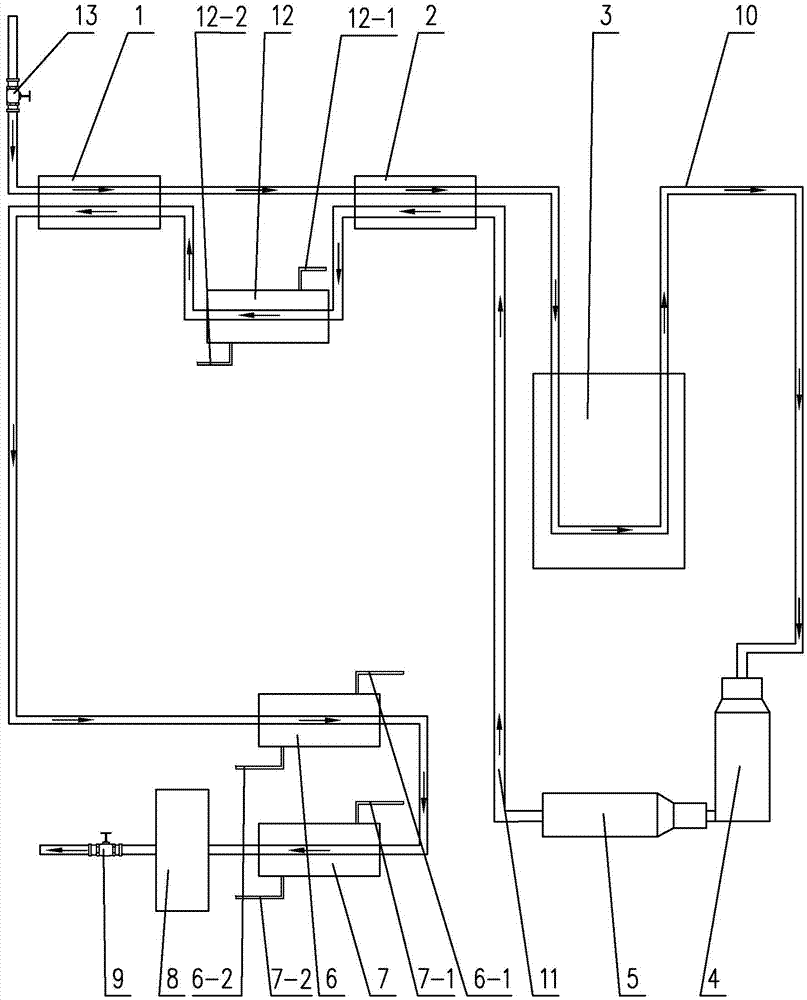

[0013] Specific implementation mode one: combine figure 1 To illustrate, a nitrogen non-circulation heating device for partial oxidation system described in this embodiment includes a feed gas preheater 1, a mixed gas preheater 2, a heating furnace 3, a reformer 4, a waste heat boiler 5, and a desalinated water preheater. Heater 6, water cooler 7, separator 8, vent valve 9 and boiler feed water preheater 12, the nitrogen delivery pipe passes through the first connecting pipe 10 from front to back through the feed gas preheater 1, the mixed gas preheater 2, the heating furnace 3 and the reformer 4, the exhaust end of the reformer 4 is connected to the waste heat boiler 5, the exhaust end of the waste heat boiler 5 is connected to the second connecting pipe 11, and the second connecting pipe 11 passes through from front to back in sequence Overmixed gas preheater 2, boiler feed water preheater 12, raw gas preheater 1, desalted water preheater 6 and water cooler 7, the exhaust en...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 To illustrate, a regulating valve 13 is provided at the starting end of the first connecting pipeline 10 in this embodiment. Other compositions and connection methods are the same as those in Embodiment 1.

[0024] Such a design can adjust the speed of nitrogen gas entry at any time according to needs.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 Note that the upper end of the water cooler 7 in this embodiment is connected with a first condensate outlet pipe 7-1, and the lower end of the water cooler 7 is connected with a first condensate inlet pipe 7-2. Other compositions and connection methods are the same as those in the second embodiment.

[0026] Such a design can realize rapid cooling of nitrogen.

[0027] Specific implementation mode four: combination figure 1 Note that the upper end of the desalted water preheater 6 in this embodiment is connected with a second condensate outlet pipe 6-1, and the lower end of the desalinated water preheater 6 is connected with a second condensate inlet pipe 6-2. Other compositions and connection modes are the same as those in Embodiment 1, 2 or 3.

[0028] Such a design can realize rapid cooling of nitrogen.

[0029] Specific implementation mode five: combination figure 1 Note, the upper end of the boiler feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com