Compound fertilizer special for flue-cured tobacco variety NC102

A flue-cured tobacco variety and compound fertilizer technology, applied in the agricultural field, can solve problems such as increased fertilizer costs, excessive nitrogen application, and unreasonable nutrient distribution ratio, so as to increase the aroma and potassium content of tobacco leaves, improve the yield and quality of tobacco leaves, and improve The Effect of Tobacco Leaf Appearance Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

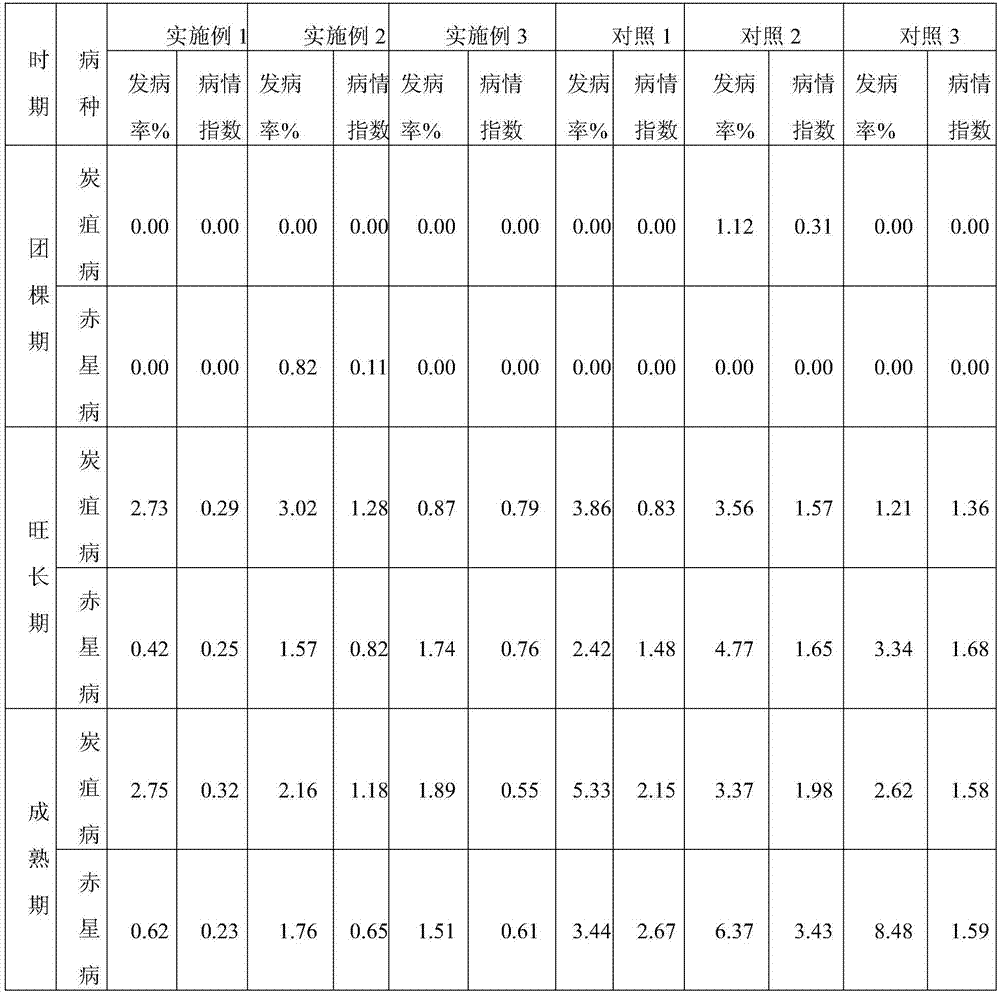

Embodiment 1

[0020] The preparation method of the special compound fertilizer for flue-cured tobacco variety NC102: it is made by drum steam granulation process, that is, 11 parts of ammonium nitrate, 13 parts of diammonium phosphate, 38 parts of potassium sulfate and 38 parts of diatomaceous earth are pre-crushed respectively, and then Stir and mix, then break into powder, and drum granulate the mixed components. The granulation process and conditions are as follows: steam is added to the drum, and it is advisable to start agglomeration of the mixed elemental fertilizer powder, which will be roughly The agglomerated powder is fed into the drying kiln for drying through the belt, and the inlet temperature of the drying kiln is controlled at 140°C. The powder is further granulated and dried in the drying kiln, cooled by the cooling kiln, and the finished product is packed after passing through a 5-mesh sieve. Bags, oversized or undersized granules are returned for further re-granulation. Th...

Embodiment 2

[0022] The preparation method of the special compound fertilizer for flue-cured tobacco variety NC102: it is made by drum steam granulation process, that is, 12 parts of ammonium nitrate, 14 parts of diammonium phosphate, 39 parts of potassium sulfate and 35 parts of diatomaceous earth are respectively pre-crushed, and then Stir and mix, then break into powder, and drum granulate the mixed components. The granulation process and conditions are as follows: steam is added to the drum, and it is advisable to start agglomeration of the mixed elemental fertilizer powder, which will be roughly The agglomerated powder is fed into the drying kiln for drying through the belt, and the inlet temperature of the drying kiln is controlled at 140°C. The powder is further granulated and dried in the drying kiln, cooled by the cooling kiln, and the finished product is packed after passing through a 5-mesh sieve. Bags, oversized or undersized granules are returned for further re-granulation. Th...

Embodiment 3

[0024] The preparation method of the special compound fertilizer for flue-cured tobacco variety NC102: it is made by drum steam granulation process, that is, 13 parts of ammonium nitrate, 15 parts of diammonium phosphate, 40 parts of potassium sulfate and 32 parts of diatomaceous earth are pre-crushed respectively, and then Stir and mix, then break into powder, and drum granulate the mixed components. The granulation process and conditions are as follows: steam is added to the drum, and it is advisable to start agglomeration of the mixed elemental fertilizer powder, which will be roughly The agglomerated powder is fed into the drying kiln for drying through the belt, and the inlet temperature of the drying kiln is controlled at 140°C. The powder is further granulated and dried in the drying kiln, cooled by the cooling kiln, and the finished product is packed after passing through a 5-mesh sieve. Bags, oversized or undersized granules are returned for further re-granulation. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com