High-temperature-resistant shock-absorption rubber pad for automobile engines

A technology for shock-absorbing rubber pads and automobile engines, which is applied in the field of high-temperature-resistant shock-absorbing rubber pads for automobile engines, can solve problems such as poor high-temperature resistance performance, and achieve the effects of improved high-temperature resistance performance and excellent aging resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

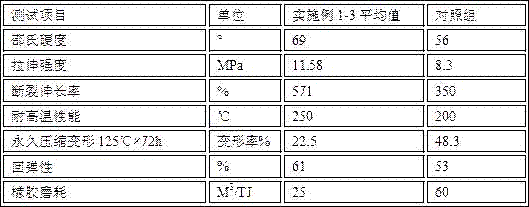

Examples

Embodiment 1

[0015] The high-temperature shock-absorbing rubber pad of this embodiment is prepared from the following raw materials in parts by weight: 30 parts of natural rubber, 15 parts of butadiene rubber, 10 parts of silicone rubber, 3 parts of stearic acid, 1.8 parts of zinc oxide, nano-dioxide 1 part of silicon, 2 parts of anti-aging agent, 1 part of glass fiber, 1 part of accelerator, 0.5 part of high alumina powder.

Embodiment 2

[0017] 25 parts of natural rubber, 23 parts of butadiene rubber, 18 parts of silicone rubber, 4 parts of stearic acid, 2.5 parts of zinc oxide, 3 parts of nano-silica, 1 part of anti-aging agent, 1.5 parts of glass fiber, 3 parts of accelerator, high 1.5 parts of aluminum powder.

Embodiment 3

[0019] The high-temperature shock-absorbing rubber pad of this embodiment is prepared from the following raw materials in parts by weight: 40 parts of natural rubber, 25 parts of butadiene rubber, 25 parts of silicone rubber, 5 parts of stearic acid, 1.5 parts of zinc oxide, nano-dioxide 5 parts of silicon, 3 parts of anti-aging agent, 2 parts of glass fiber, 5 parts of accelerator, 2 parts of high alumina powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com