A kind of polyurethane flexible foam composite material and its production process

A polyurethane soft foam and production process technology, which is applied in the field of polyurethane soft foam composite materials and its production process, can solve the problems of decreased mite repellent effect and loss of coat repellent components, and achieve the effects of saving investment, stable properties, and not easy to separate out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of semi-open cell polyurethane soft foam particle composite material

[0030] Step 1, preparing semi-open-cell polyurethane soft foam particles

[0031] 1.1 Put polyether polyol, crosslinking agent, catalyst, foaming stabilizer, and cell opening agent into the A raw material tank according to the process requirements, and fully stir and mix them to obtain A material;

[0032] 1.2 According to the process requirements, put polyether polyol and isocyanate into the raw material tank of B, stir and mix them well to obtain material B;

[0033] 1.3 Fully mix material A and material B according to the ratio of one to one and inject into the foaming chamber;

[0034] 1.4 Keep warm at 50-90°C for 1-5h;

[0035] 1.5 Take out the foamed semi-open polyurethane flexible foam from the foaming chamber, cool to room temperature and crush it into particles with a maximum particle size of 2-6mm. The particle size of particle should be advisable with the feeding pip...

Embodiment 2

[0047] Example 2 Preparation of Composite Material Containing Mite Inhibiting Components

[0048] Step 1, preparing particle materials containing mite-inhibiting components

[0049] 1.1 Put polyether polyol, crosslinking agent, catalyst, foaming stabilizer, and cell opening agent into the A raw material tank according to the process requirements, and fully stir and mix them to obtain A material;

[0050] 1.2 Put polyether polyol, isocyanate, and dimethyl phthalate into the raw material tank of B according to the process requirements, and mix them well to obtain material B; among them, dimethyl phthalate is selected from Shanghai Jinshan Jingwei Chemical Co., Ltd. The company's industrial-grade products;

[0051] 1.3 Fully mix material A and material B according to the ratio of one to one and inject into the foaming chamber;

[0052] 1.4 Keep warm at 50-70°C for 1-5h;

[0053] 1.5 Take out the foamed semi-open polyurethane flexible foam from the foaming chamber, cool to room...

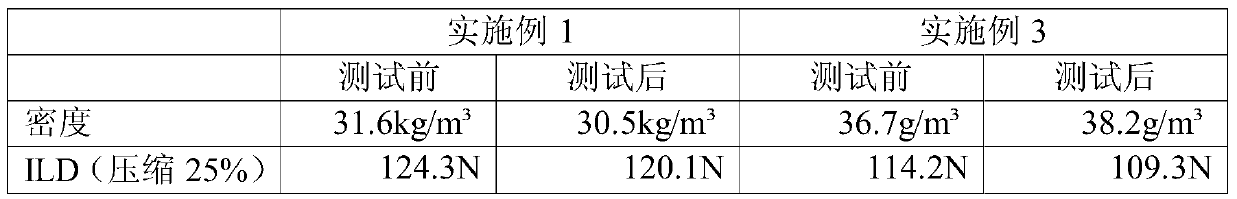

Embodiment 3

[0055] Example 3 Preparation of Closed Cell Polyurethane Soft Foam Particle Composite Material

[0056] Step 1, using recycled materials to prepare closed-cell polyurethane soft foam particles

[0057] 1.1 Pulverize the recovered closed-cell polyurethane soft foam to obtain particles with a maximum particle size of 2 to 3 mm. The particle diameter of particle should be advisable with the feed pipeline of the high-pressure polyurethane foaming machine that step 4 is used;

[0058] 1.2 Soak and stir the closed-cell polyurethane soft foam particles with an organic solvent, and clean the residual dust, release agent, plasticizer, etc. on the surface, and the cleaning time is 30 to 60 minutes;

[0059] 1.3 Separate the closed-cell polyurethane flexible foam particles from the organic solvent, and completely volatilize the organic solvent remaining on the surface. Step 2: Prepare raw materials for substrate production

[0060] 2.1 According to the finished product density is 25-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com