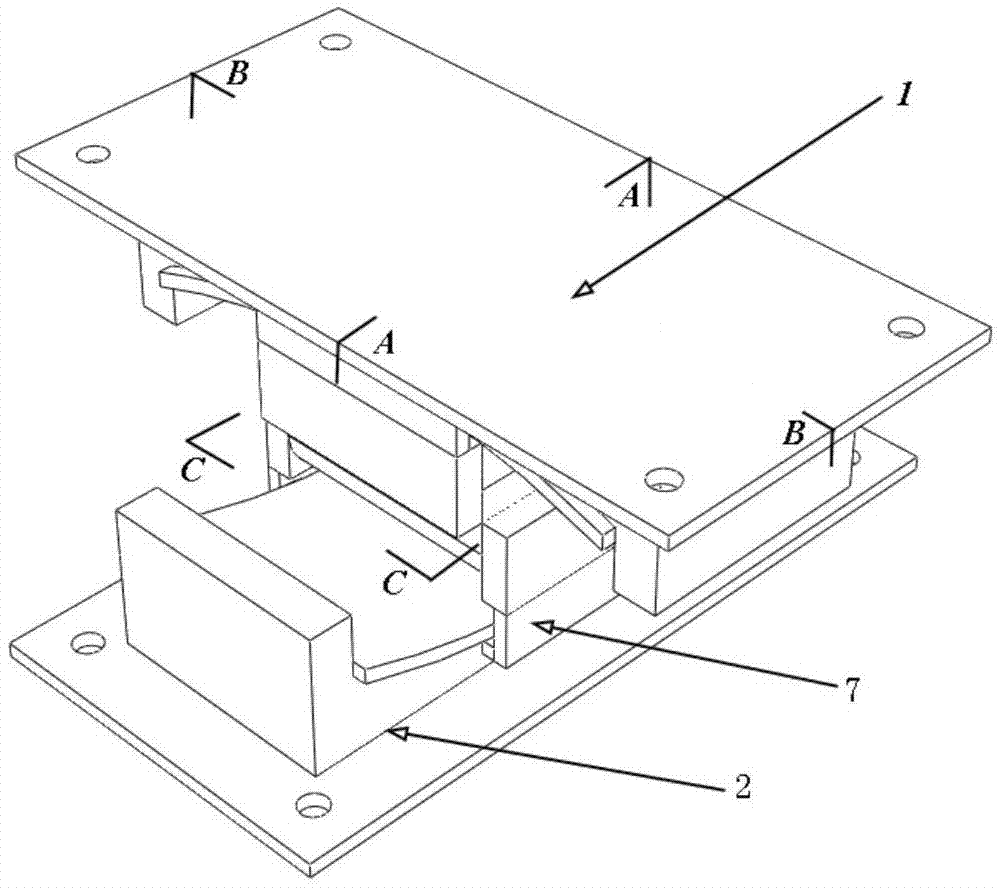

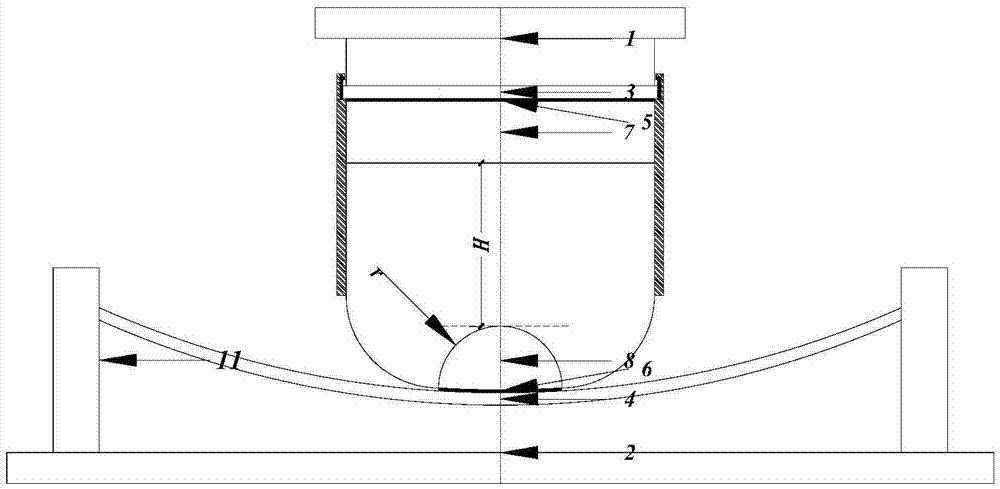

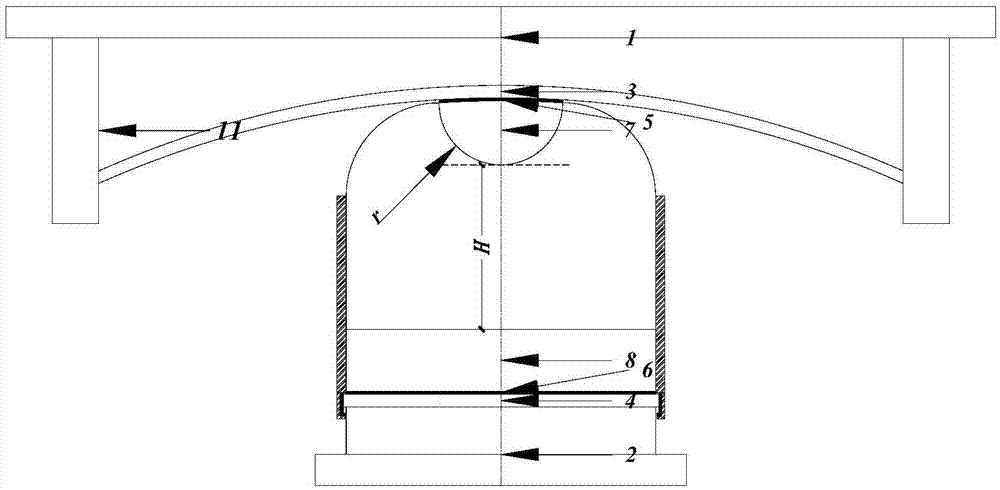

Two-way variable-camber friction pendulum earthquake insulation bearing

A technology of seismic isolation bearing and friction pendulum, which is applied in earthquake protection, bridge parts, bridges, etc., can solve the problems of poor seismic isolation effect, unsuitable consumption of input engineering structure energy, poor self-reset function, etc., and achieves simple structure and seismic isolation. Good effect and strong self-reset function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take a 16×10 4 m 3 Taking a liquefied natural gas (abbreviated as LNG) storage tank as an example, the patent of the present invention is further described. The sectional view of the outer tank of the LNG storage tank is as follows: Figure 8 As shown, the bottom plate of the platform is located at -1.2~±0.000m, the area above ±0.000m is the main part of the outer tank, the inside radius of the cylinder body is 41m, the wall thickness is 0.8m, the radius of the dome ball of the storage tank is 82m, and the thickness is 0.4m , the concrete strength grade of the outer tank of the storage tank is C50. The diameter of the inner tank is 80m, and it is divided into 12 layers along the height direction, and the thickness of each layer from bottom to top is as follows: Figure 8 shown. The distance between the outer tank and the inner tank is 1m. The normal maximum operating liquid level of the LNG storage tank is 31.847m, and the design liquid level is 34.760m.

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com