Single-sensor double closed-loop urea-selective catalytic reduction (SCR) feedback control method based on observer

A feedback control and single-sensor technology, which is applied in the electronic control of exhaust treatment devices, machines/engines, diagnostic devices of exhaust treatment devices, etc., can solve problems such as ammonia escape and signal errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

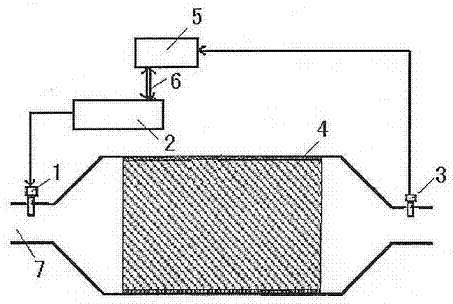

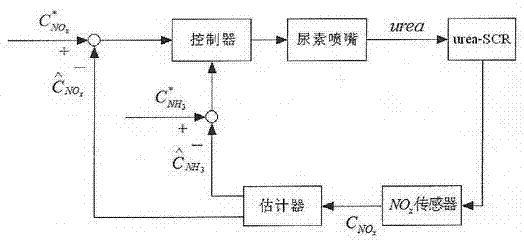

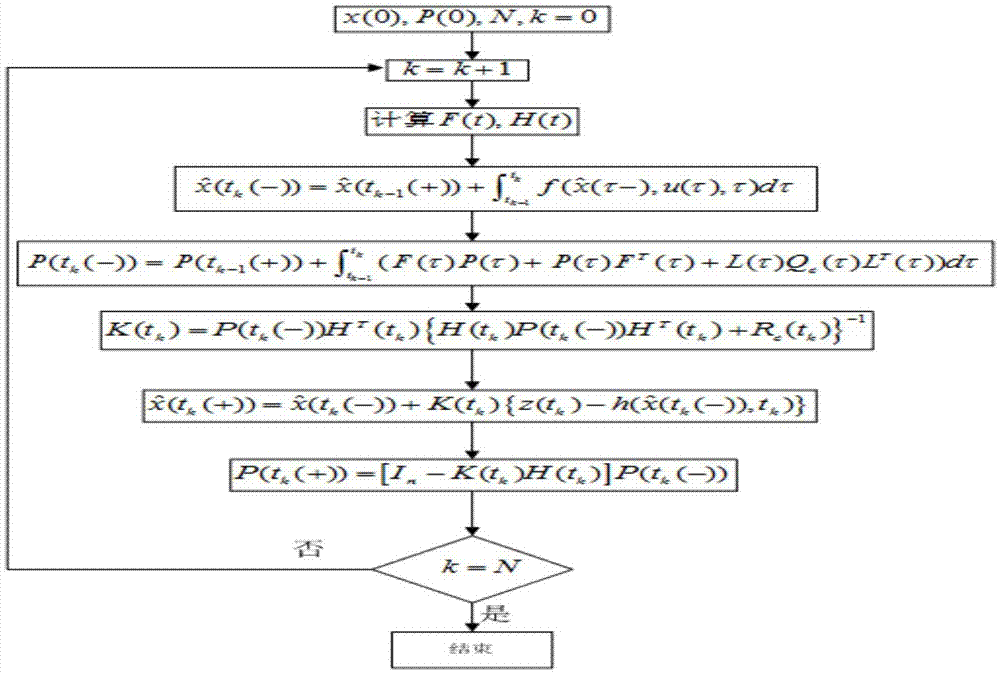

[0062] see figure 1 , figure 2 and image 3 As shown, it is an embodiment of the present invention, and this embodiment is based on NO x The map calibration test of the relationship between sensor cross-sensitivity factor and exhaust temperature, based on the urea-SCR system mathematical model, applied the nonlinear Kalman filter observation theory, designed a data / mechanism-based and Parameter Observer. Taking the difference between the above two estimated quantities and their respective target values as the controller input, a double closed-loop feedback controller for urea injection is designed. refer to figure 1 , the present invention mainly uses the observer / controller and the NO installed at the exhaust end of the urea-SCR system x The sensor is the main component, and the urea injection feedback control system is constructed. The method specifically includes the following steps:

[0063] 1. Collect NO x The signal from the sensor 3 is sent to the observer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com