Optical fiber grating temperature sensor wavelength shift correction method and temperature measuring device

A technology of temperature sensor and wavelength shift, which is used in measurement devices, thermometer testing/calibration, thermometers, etc. It can solve the problems of inapplicable application requirements, increased errors, and large amount of calculation, so as to reduce the amount of calculation and expand temperature measurement. Effects with high range and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

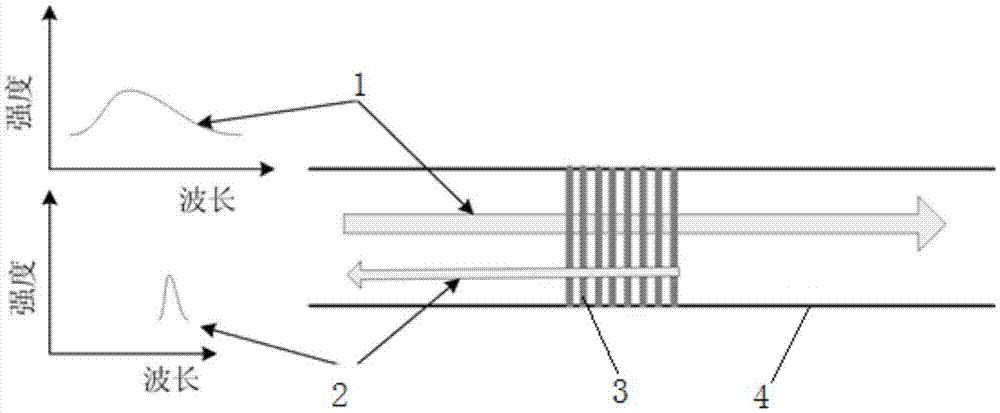

[0030] A fiber grating temperature sensor wavelength offset correction method, using the wavelength offset cubic fitting method for correction, the fitting formula is:

[0031] T=K 0 +K 1 Δλ+K 2 Δλ 2 +K 3 Δλ 3 (1)

[0032] Among them: T is the measured temperature, Δλ is the wavelength shift relative to a reference reflection wavelength, K 0 、K 1 、K 2 、K 3 is a constant and requires actual calibration.

[0033] Based on the center wavelength of the reflected wave at 0°C, the fitting formula is:

[0034] T=K 1 Δλ+K 2 Δλ 2 +K 3 Δλ 3 (2)

[0035] Where: Δλ is the center wavelength shift of the reflected wave relative to the reflected wave at 0°C.

[0036] The existing quadratic fitting formula is:

[0037] λ=a+bT+cT 2 (3)

[0038] Among them: λ is the wavelength of the reflected wave, T is the measured temperature, a, b, and c are cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com