Lens having self-cleaning colorful function and preparation method thereof

A lens and colorful technology, applied in optical components, optics, instruments, etc., can solve problems such as difficulty in finding the position of the lens accurately, poor anti-fouling ability of the lens, and reduced image quality, etc., to achieve shielding of harmful light, remarkable anti-fouling effect, Optimize the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation process of the lens with self-cleaning colorful function is as follows:

[0056] 1. Put the soda-lime glass into detergent, acetone, alcohol, and deionized water in order to ultrasonically clean it for ten minutes, and then dry it with nitrogen after taking it out.

[0057] 2. Transfer the cleaned glass to the evaporation chamber and use electron beams to evaporate Cr to a thickness of 50nm to complete the preparation of the high reflection base film R.

[0058] 3. Pass the glass to the spin coating machine, spin coat UV photoresist, and put it into the drying oven to dry the hard film after spin coating.

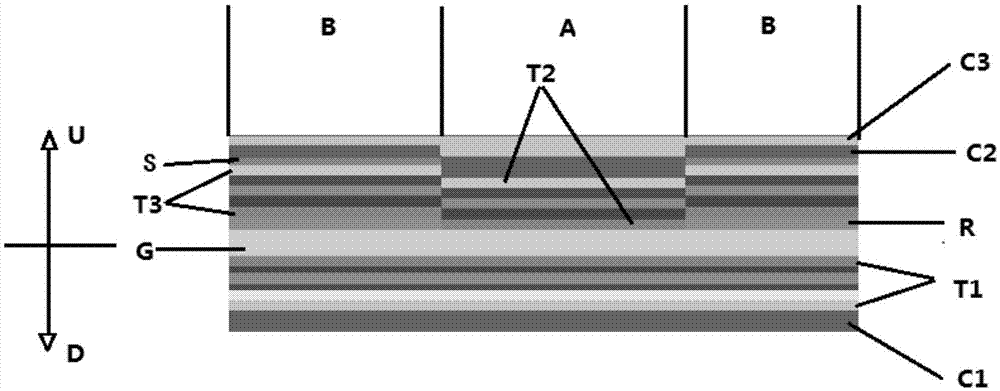

[0059] 4. After the film hardening is completed, cover the upper surface with the mask plate Y (the exposure area of the mask plate Y completely coincides with the high transmission area A), expose it under UV light, and use KOH solution to etch the high transmission area A after exposure.

[0060] 5. After the etching is completed, clean with the ...

Embodiment 2

[0072] The preparation process of the lens with self-cleaning colorful function is as follows:

[0073] 1. Put the soda-lime glass into detergent, acetone, alcohol, and deionized water in order to ultrasonically clean it for ten minutes, and then dry it with nitrogen after taking it out.

[0074] 2. Transfer the cleaned glass into the evaporation chamber and use the electron beam to evaporate Cr to a thickness of 40nm to complete the preparation of the high reflection base film R.

[0075] 3. Pass the glass to the spin coating machine, spin coat UV photoresist, and put it into the drying oven to dry the hard film after spin coating.

[0076] 4. After the film hardening is completed, cover the upper surface with the mask plate Y (the exposure area of the mask plate Y completely coincides with the high transmission area A), expose it under UV light, and use KOH solution to etch the high transmission area A after exposure.

[0077] 5. After the etching is completed, clean with...

Embodiment 3

[0089] The preparation process of the lens with self-cleaning colorful function is as follows:

[0090] 1. Put the soda-lime glass into detergent, acetone, alcohol, and deionized water in order to ultrasonically clean it for ten minutes, and then dry it with nitrogen after taking it out.

[0091] 2. Transfer the cleaned glass to the evaporation chamber and use electron beams to evaporate Cr to a thickness of 60nm to complete the preparation of the high reflection base film R.

[0092] 3. Pass the glass to the spin coating machine, spin coat UV photoresist, and put it into the drying oven to dry the hard film after spin coating.

[0093] 4. After the film hardening is completed, cover the upper surface with the mask plate Y (the exposure area of the mask plate Y completely coincides with the high transmission area A), expose it under UV light, and use KOH solution to etch the high transmission area A after exposure.

[0094] 5. After the etching is completed, clean with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com