Robot inspection system and inspection method for cold region transformer substation

A patrol inspection system and substation technology, applied in the direction of two-dimensional position/channel control, etc., can solve problems such as low efficiency and poor detection quality, and achieve the effects of low environmental dependence, strong environmental adaptability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

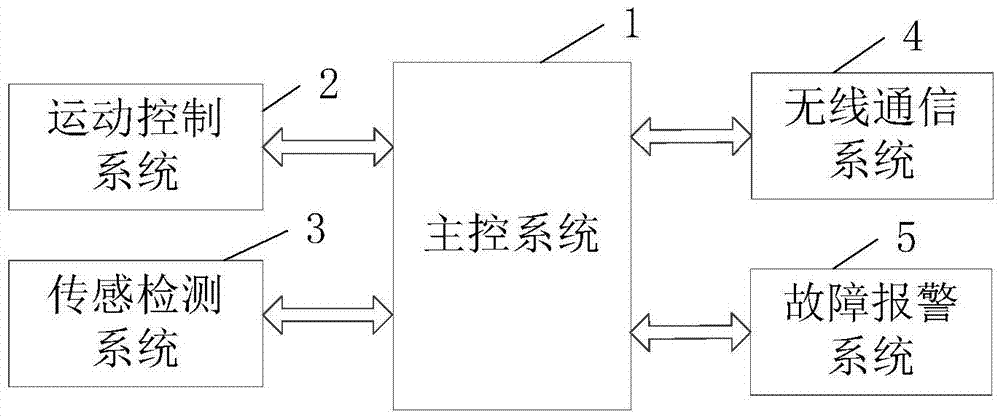

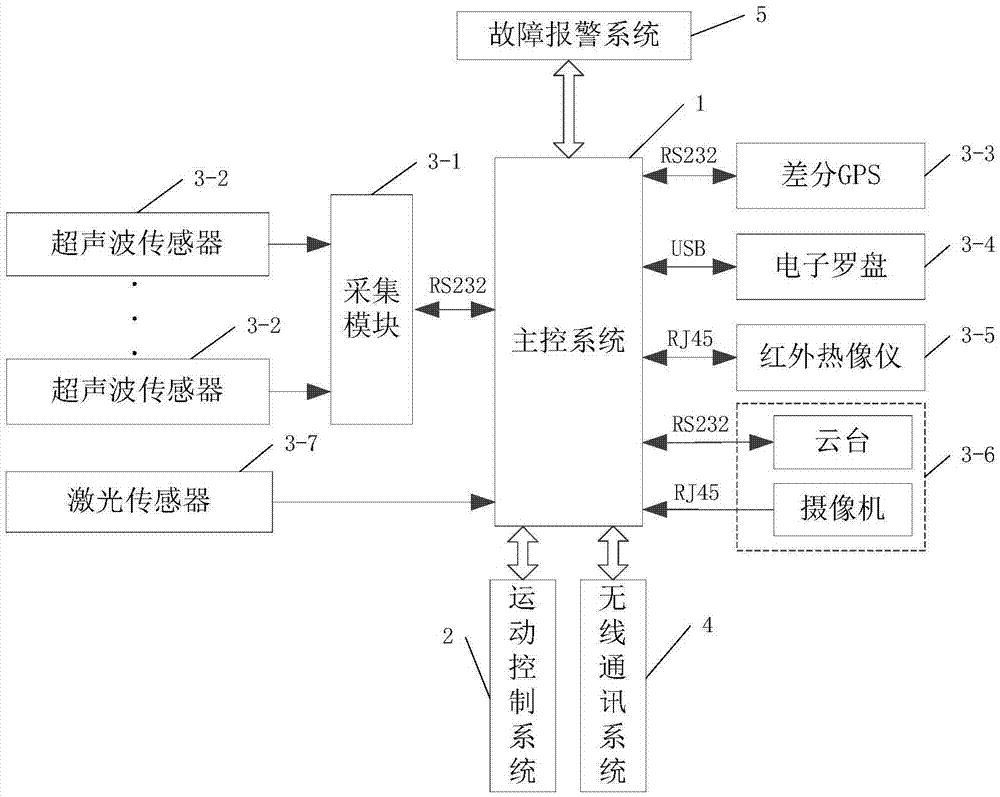

[0077] Specific implementation mode one: see figure 1 Describe this embodiment, a robot inspection system for substations in cold regions described in this embodiment, which includes a main control system 1, a motion control system 2, a sensor detection system 3, a wireless communication system 4 and a fault alarm system 5;

[0078] The main control system 1 is used to schedule tasks for the inspection robot, and is also used to receive environmental perception signals, orientation data, temperature data, environmental images and pointer instrument images, and send motion control signals according to the environmental perception signals and orientation data. The temperature data is compared with the set temperature threshold. When the collected temperature data exceeds the set temperature threshold, an alarm control signal is sent, and the received environmental image is matched with the image in the fault type model library. When the match is successful, Send an alarm contro...

specific Embodiment approach 2

[0085] Embodiment 2: The difference between this embodiment and the robot inspection system for substations in cold regions described in Embodiment 1 is that the specific process of reading the meter data of the substation according to the received pointer meter image is as follows: :

[0086] Firstly, the image of the pointer instrument is preprocessed. The preprocessing process is to remove the interference noise in the image of the pointer instrument by means of median filtering and image enhancement, and obtain the dial information;

[0087] Secondly, Hough transformation is performed on the obtained dial information to obtain the pointer straight line;

[0088] Finally, the barycenter method is used to extract the center of gravity of the scale in the straight line of the pointer, and the least squares circle is used to fit the center of gravity of the scale to the center of the dial in the extracted dial information, and the meter reading is calculated by using the defle...

specific Embodiment approach 3

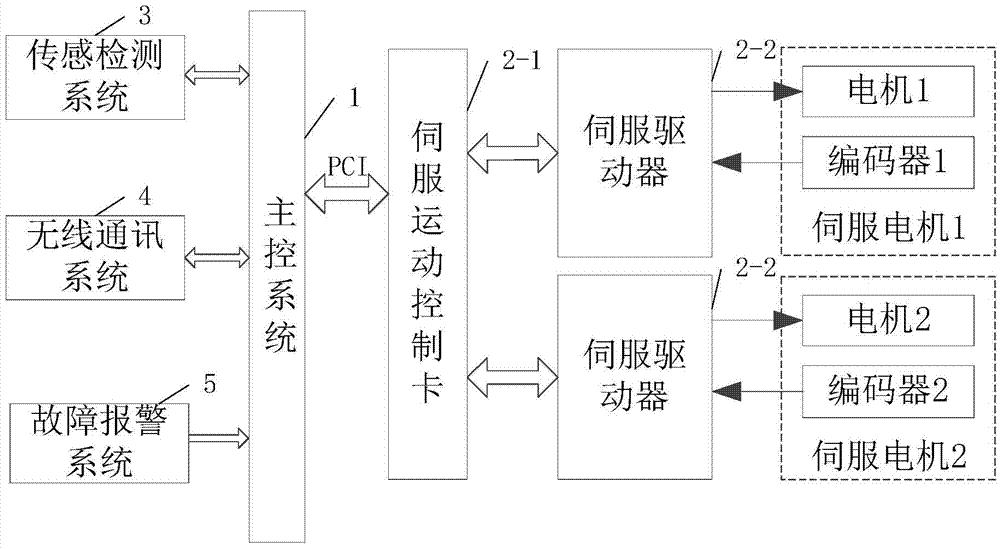

[0090] Specific implementation mode three: see figure 2 Describe this embodiment. The difference between this embodiment and the robot inspection system for substations in cold regions described in the first embodiment is that the motion control system 2 includes a servo motion control card 2-1, two Servo drive 2-2;

[0091] The servo motion control card 2-1 is used to send the servo drive signal according to the motion control signal;

[0092] The servo driver 2-2 is used to receive the servo drive signal, and is also used to drive a DC servo motor of the inspection robot.

[0093] In this embodiment, the motion control system of the inspection robot realizes the basic control such as forward, backward, and turning of the mobile platform of the inspection robot, as well as the adjustment control of running speed and position. servo motor.

[0094] Adopt the "industrial computer + servo motion control card + servo driver + servo motor" control method to realize the servo c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com