Method for determining stage difference of horizontal directional reaming

A technology of horizontal directional drilling and determination method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as hole wall collapse, and achieve the effect of reducing the possibility of hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

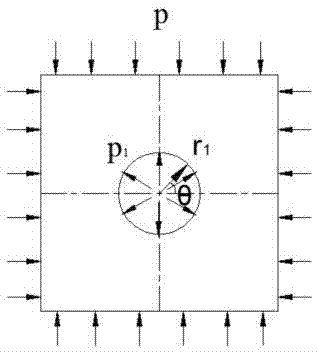

[0073] To further illustrate the present invention, this method is used to determine the reaming level difference of a certain horizontal directional crossing project. The project is: horizontal directional drilling through the stratum dominated by silty clay, the diameter of the pipe to be laid is 914mm, the buried depth is 10m, and the mud density is 1000Kg / m 3 , The diameter of the hole left after the first level of reaming is 609.6mm. The physical and mechanical properties of silty clay are shown in Table 1 below:

[0074] Table 1

[0075]

[0076] The following are the specific steps of the calculation:

[0077] Determine the diameter of the final hole: for silty clay, the engineering coefficient C value can be taken as 1.5, and the diameter of the final hole is obtained as D=CD p =1.5*914=1371 mm.

[0078] Taking β=0.3, according to the formulas (16) and (17), it can be obtained that after the first stage of reaming, the radius of the plastic zone is 394.29mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com