Glue filling fixture and glue filling method for traveling wave tube electron gun

A technology of electron guns and traveling wave tubes, which is applied in the field of fixtures filled with glue for traveling wave tube electron guns, can solve problems such as loosening or dislocation of compensating magnetic blocks, changes in dynamic parameters of traveling wave tubes, and affecting the magnetic field focus of rare earth magnetic rings, etc., to achieve Improve product efficiency and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

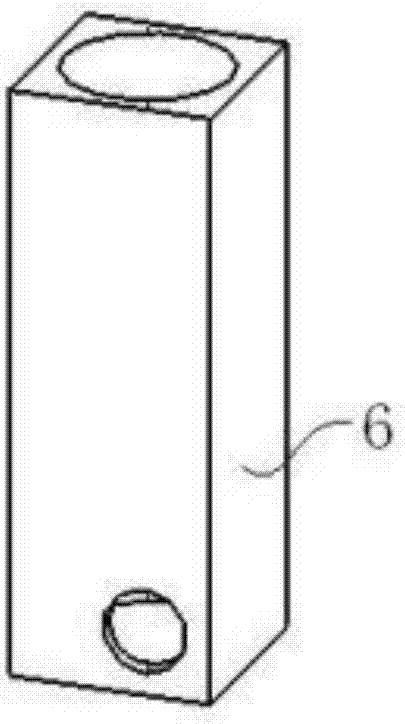

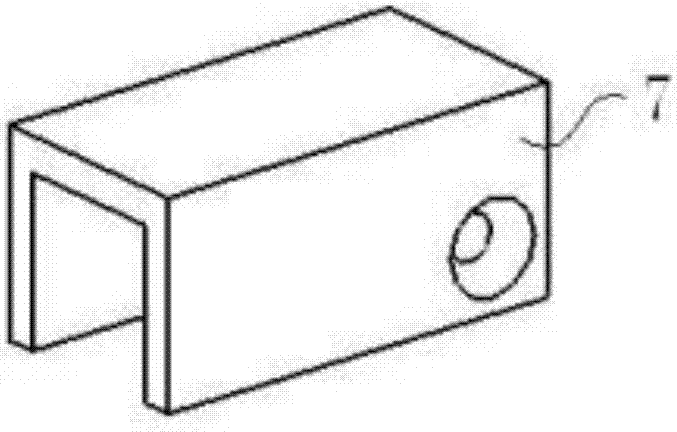

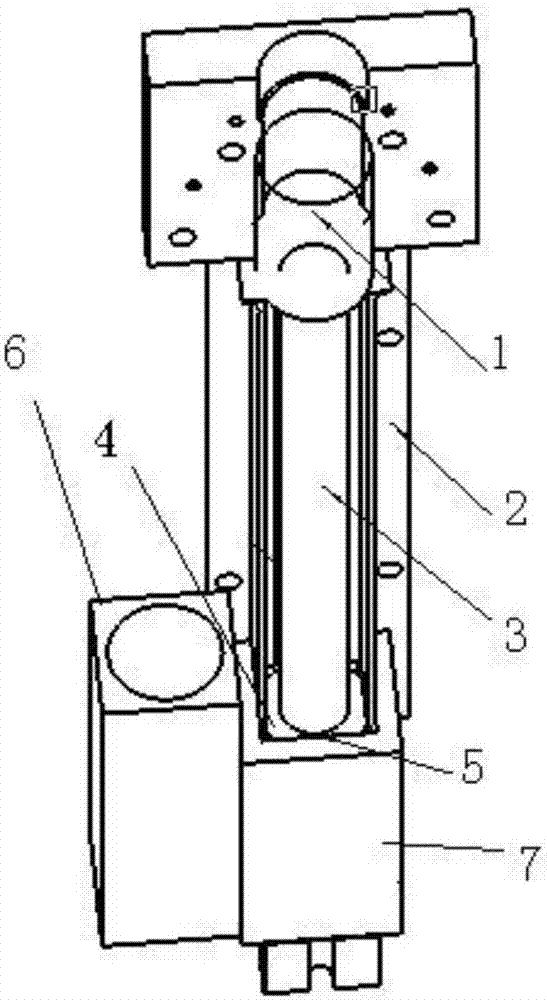

[0032] The glue filling fixture of the traveling wave tube electron gun in the first embodiment includes a "Π" shaped container, and the glue filling fixture is set on one end of the electron gun through the opening side of the "Π" shaped container, and the glue filling fixture also includes a square The diversion container is provided with a φ10mm through hole on the side near the bottom of the electron gun. The bottom end of the "∏" shaped container is kept flat, and the height of the diversion container is higher than that of the "∏" shaped container. The φ 10mm through hole that the through hole of the container communicates; the through hole of the diversion container is a circular hole in the present embodiment, and when the diversion container is fixedly connected with the "Π" shape container, the center of circle of the through hole of the diversion container is in line with the The centers of the through-holes of the "∏"-shaped container are roughly coincident.

[00...

Embodiment 2

[0041] The glue filling fixture of the traveling wave tube electron gun in the second embodiment is roughly the same as the glue filling fixture of the traveling wave tube electron gun in the first embodiment, the main difference is that the through hole of the "∏" shaped container in the second embodiment is a conical hole The large circular hole of the conical hole is placed on the outer surface of the "∏" shaped container, the small circular hole of the conical hole is placed on the inner surface of the "Π" shaped container, the diameter of the large circular hole of the conical hole is φ12mm, and the circular hole of the diversion container The diameter is φ10mm; the through hole of the diversion container in this embodiment is a circular hole, and when the diversion container is fixedly connected with the "Π" shaped container, the center of circle of the diversion container and the great circle of the "Π" shaped container The centers of the holes are roughly coincident. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com