Intermediate frequency power supply heating system

A heating system, intermediate frequency power supply technology, applied in induction heating, induction heating control, electrical components and other directions, can solve the problems of occupying a lot of space, increasing initial investment, single function of equipment use, etc., to achieve convenient use, reduce volume, meet the output matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] see figure 1 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

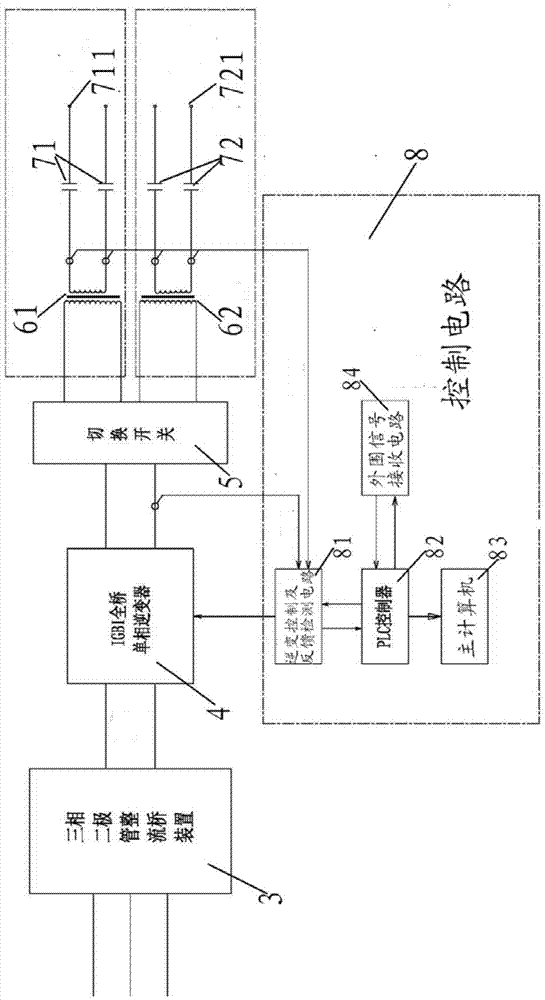

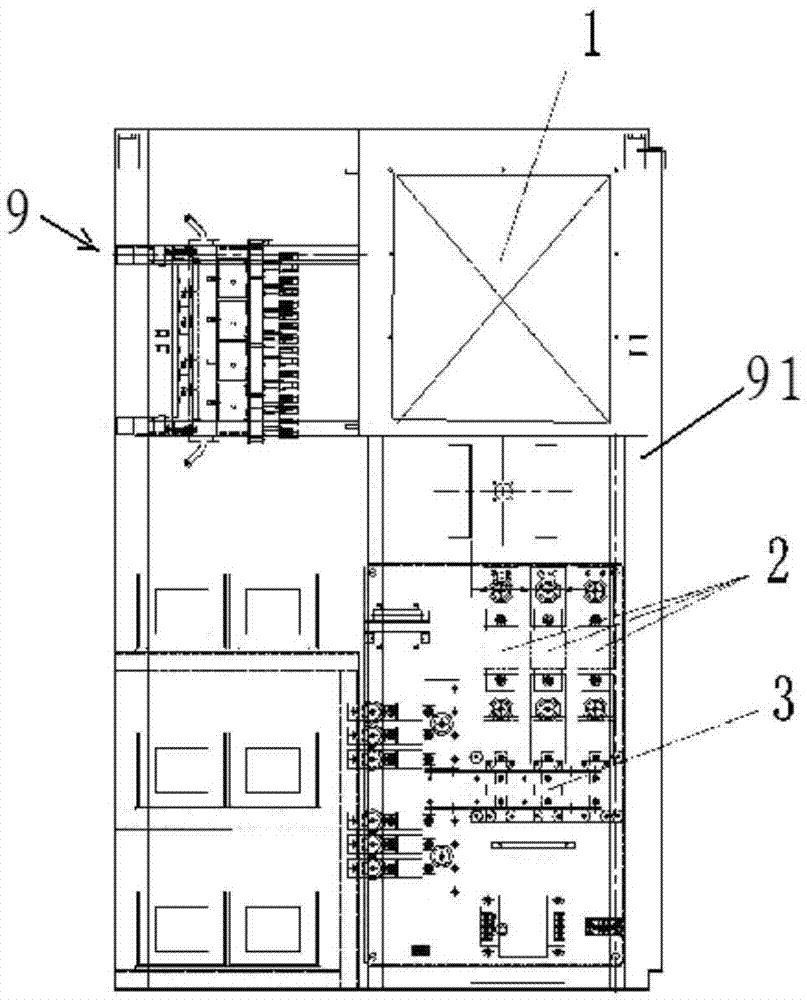

[0025] see figure 1 , an intermediate frequency power supply heating system of the present invention, including a main circuit breaker 1, a fast fuse 2, a three-phase diode rectifier bridge device 3, an IGBT full-bridge single-phase inverter 4, a switch 5, and a whole tube heating output transformer 61 And weld seam heating output transformer 62. The main circuit breaker 1 receives external three-phase AC current input, and the main circuit breaker 1 is connected to the three-phase diode rectifier bridge device 3 through a fast fuse 2 . The three-phase diode rectifier bridge device 3 is used to convert the external three-phase AC current into a single-phase DC current.

[0026] The output end of the three-phase diode rectifier bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com