Operation protective garment with back-load type filter

A protective clothing and filter technology, which is applied in protective clothing, clothing, clothing, etc., can solve the problems of limited filtering ability of masks and inability of protective clothing to fully protect the skin, and achieve light weight of the main body of protective clothing, improved comfort, and enhanced The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

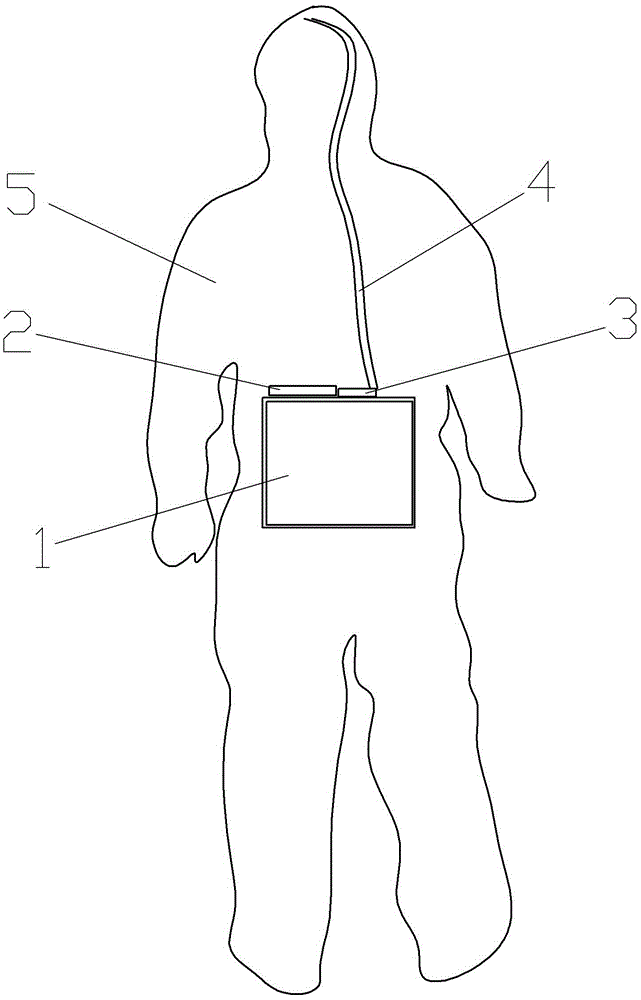

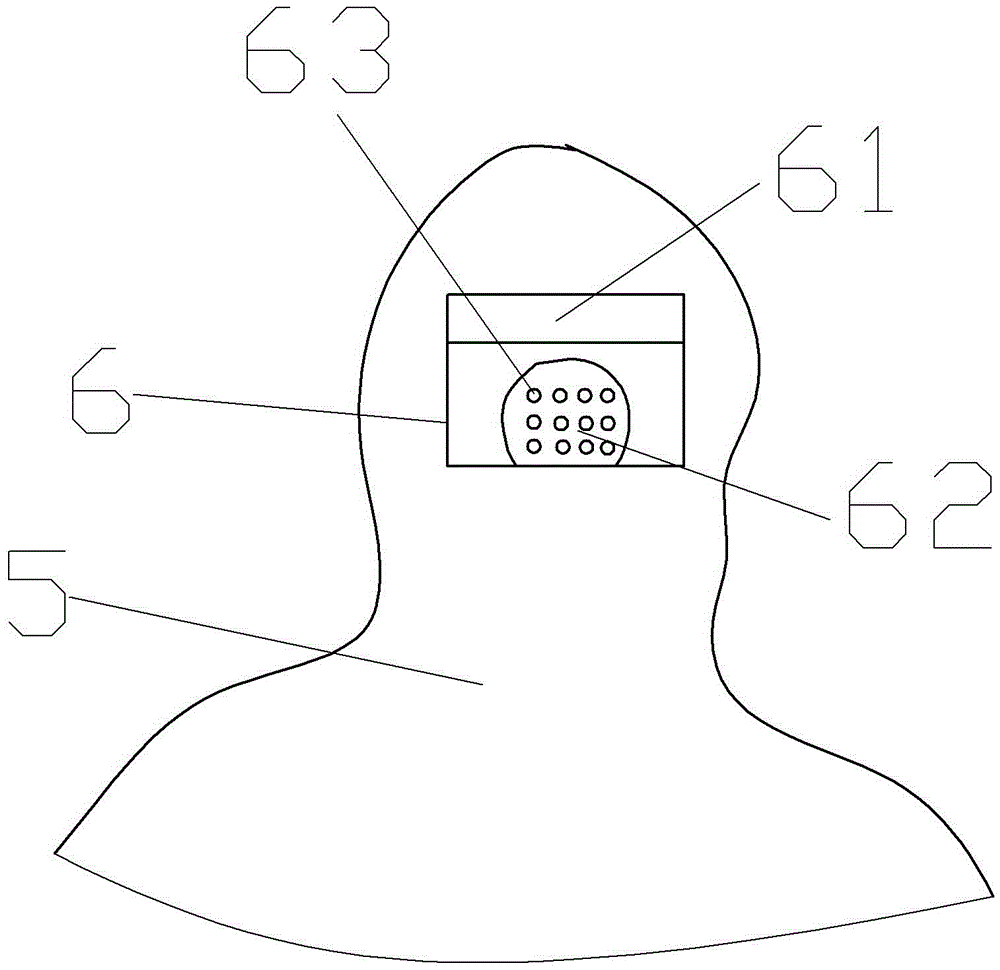

[0019] Such as figure 1 , figure 2 Shown: the back filter operation protective clothing includes a protective clothing main body 5, a mask 6 and a filter main body arranged outside the protective clothing main body 5; wherein the protective clothing main body 5 is made of non-woven fabric or nylon, and the mask 6 is sewn on the protective clothing Clothing main body 5, so that mask 6 and protective clothing main body 5 form a closed space; filter main body includes filter box body 1, micro fan 3, battery 2 and air pipe 4; filter box body 1 is provided with air inlet and air outlet, battery 2 Fixed on the filter box 1, the micro fan 3 is also fixed on the filter box 1, and the air inlet of the micro fan 3 corresponds to the air outlet of the filter box 1, and the air outlet of the micro fan 3 is connected to the air duct One end of trachea 4 is connected, and the other end of trachea 4 stretches into the inside of protective clothing main body 5; The interior of the filter b...

Embodiment 2

[0023] The difference between Embodiment 2 and Embodiment 1 is that the mask in Embodiment 2 is an anti-fog mask made of anti-fog glass, and an air outlet is provided under the back of the main body of the protective clothing. One-way valve, the one-way valve can only make the air flow from the main body of the protective clothing to the outside; while the air outlet end of the trachea extends to the vicinity of the head. Compared with the first embodiment, the second embodiment has a simpler structure and is more convenient to wear, and it can prevent the exhaled gas from forming fog on the mask and obstructing the line of sight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com