Nanostructure high-flux reverse osmosis membrane for seawater desalination and preparation method therefor

A reverse osmosis membrane and nanostructure technology, which is applied in the field of nanostructure high-flux seawater desalination reverse osmosis membrane and its preparation, can solve the problems of high energy consumption and low flux of the system, and achieve the improvement of flux performance, quality, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

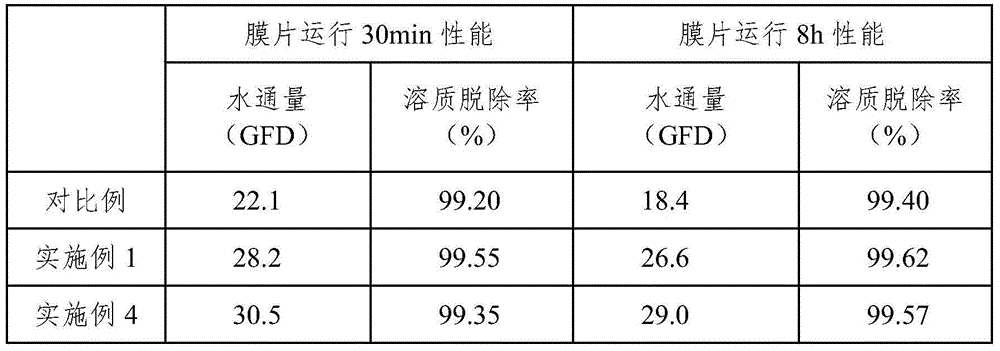

Embodiment 1

[0025] A method for preparing a nanostructured high-flux seawater desalination reverse osmosis membrane, comprising the following steps:

[0026] (1) Preparation of polymer support layer: 30g polyvinylpyrrolidone and 780gDMF are mixed and dispersed, and a stirring speed of 60r / min is used for stirring, so that polyvinylpyrrolidone is uniformly dispersed in the DMF solution, and then the stirring speed is maintained, and then Wherein add 60g of natural nanocrystals, after stirring for 30min, add polymer to it again, make the concentration of polymer in solution be 19wt%, obtain polymer solution; Polymer solution is carried out vacuum defoaming under-80kpa again Filter after treatment to obtain a bubble-free and impurity-free solution; then apply the bubble-free and impurity-free solution to the non-woven fabric substrate, then place it in deionized water, adjust the temperature to 28°C, and obtain a polymer support after treatment for 170s layer;

[0027] (2) Preparation of th...

Embodiment 2

[0038] On the basis of Example 1, the others are the same as in Example 1, a method for preparing a nanostructured high-flux seawater desalination reverse osmosis membrane, comprising the following steps:

[0039] (1) Preparation of polymer support layer: 30g polyvinylpyrrolidone and 780gDMF are mixed and dispersed, and a stirring speed of 90r / min is used for stirring treatment, so that polyvinylpyrrolidone is uniformly dispersed in the DMF solution, then the stirring speed is maintained, and then Wherein add 60g of natural nanocrystals, after stirring for 50min, add polymer to it again, make the concentration of polymer in solution be 19wt%, obtain polymer solution; Polymer solution is carried out vacuum defoaming under-81kpa again Filter after treatment to obtain a bubble-free and impurity-free solution; then apply the bubble-free and impurity-free solution to the non-woven fabric substrate, then place it in deionized water, adjust the temperature to 31°C, and obtain a polyme...

Embodiment 3

[0050] On the basis of Example 1, the others are the same as in Example 1, a method for preparing a nanostructured high-flux seawater desalination reverse osmosis membrane, comprising the following steps:

[0051] (1) Preparation of the polymer support layer: 30g polyvinylpyrrolidone and 720gDMF are mixed and dispersed, and the stirring speed is 75r / min, so that the polyvinylpyrrolidone is uniformly dispersed in the DMF solution, then the stirring speed is maintained, and then Add 30g of natural nanocrystals therein, after stirring for 40min, add polymer therein, so that the concentration of the polymer in the solution is 19wt%, to obtain a polymer solution; then the polymer solution is vacuum degassed at -80kpa Filter after treatment to obtain a bubble-free and impurity-free solution; then apply the bubble-free and impurity-free solution to the non-woven fabric substrate, then place it in deionized water, adjust the temperature to 30°C, and obtain a polymer support after treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com