Hydrophilic polyether sulfone ultrafiltration membrane and preparation method thereof

A polyethersulfone ultrafiltration membrane and hydrophilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as excellent water quality, difficulty in obtaining, and difficulty in meeting multi-performance requirements, and achieve Stable performance, improved performance and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

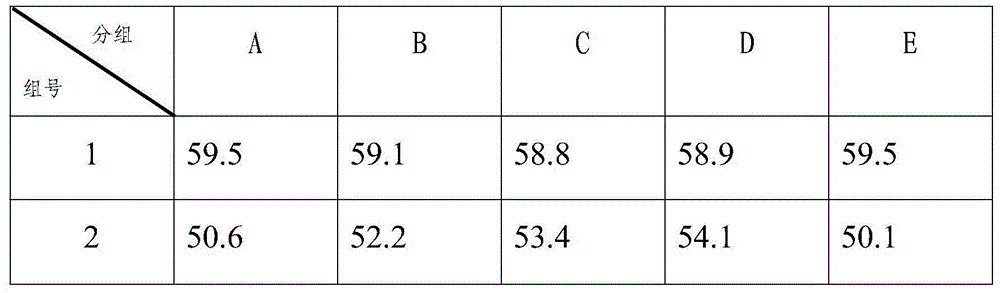

Examples

Embodiment 1

[0033] A kind of hydrophilic polyethersulfone ultrafiltration membrane, its raw material is polyethersulfone 15kg, polyvinyl alcohol 0.05kg, dimethylsulfoxide (DMSO) is 82.95kg, PEG400 (polyethylene glycol 400) is 2kg, lemon The acid is 0.05kg, and the glutaraldehyde is 0.05kg.

[0034] Its specific preparation method comprises the following steps:

[0035] (1) Dissolve polyethersulfone and polyvinyl alcohol in the organic solvent in sequence according to the above mass parts, and use a stirrer to stir evenly, then add the above mass parts porogen, and continue to use the stirrer to stir and mix evenly, let stand After 12 hours, vacuum defoaming was performed on the mixed solution to obtain a clear and transparent solution.

[0036] (2) Put the clear and transparent solution obtained in step 1) on a non-woven fabric for scraping, and then place it in water at 60° C. for reverse osmosis treatment for 15 hours.

[0037](3) the ultrafiltration membrane preliminary product that ...

Embodiment 2

[0042] A kind of hydrophilic polyethersulfone ultrafiltration membrane, on the basis of embodiment 1, other preparation method steps are with embodiment 1, and its raw material is polyethersulfone 20kg, polyvinyl alcohol 0.05kg, dimethyl sulfoxide (DMSO ) is 77.95kg, PEG400 (polyethylene glycol 400) is 2kg, citric acid is 1kg, and glutaraldehyde is 1kg.

Embodiment 3

[0044] A kind of hydrophilic polyethersulfone ultrafiltration membrane, on the basis of embodiment 1, other preparation method steps are with embodiment 1, and its raw material is polyethersulfone 18kg, polyvinyl alcohol 0.05kg, dimethyl sulfoxide (DMSO ) was 79.95kg, PEG400 (polyethylene glycol 400) was 2kg, citric acid was 0.05kg, and glutaraldehyde was 1kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com