A split forging method of bucket tooth and its mold

A split and mold technology, applied in the field of mechanical parts processing, to achieve the effects of high production efficiency, long production cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

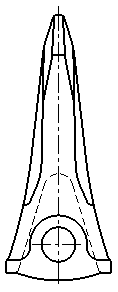

[0043] Embodiment 1, cutting along the longitudinal narrow symmetrical plane of the bucket tooth.

[0044] exist Figure 4-6 Among them, this set of molds includes a circular upper mold 1 and a lower mold 2. The upper mold 1 has guide blocks 4 on both sides, and the lower mold 2 has guide grooves 5 corresponding to the guide blocks on both sides. The upper mold and the lower mold There are also two flash grooves 6 on the working surface of the lower mold. There is a cavity 7 consistent with half bucket teeth between the two flash grooves 6 of the lower mold. The two flash grooves of the upper mold are fixed by screws 8. Forging block 9, after forging, two identical half-side bucket tooth blanks are respectively processed with grooves at the welding position, and then welded into one bucket tooth. The slit 3 is located along the longitudinal narrow symmetrical plane of the bucket tooth.

Embodiment 2

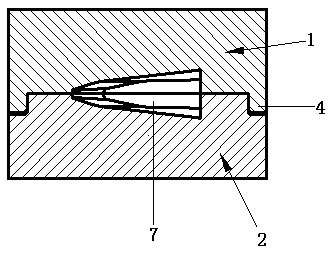

[0045] Embodiment 2, cutting along the longitudinal width symmetrical plane of the bucket teeth.

[0046] exist Figure 7-9 Among them, this set of molds includes a circular upper mold 1 and a lower mold 2. The upper mold 1 has guide blocks 4 on both sides, and the lower mold 2 has guide grooves 5 corresponding to the guide blocks on both sides. The upper mold and the lower mold There are two flash grooves 6 on the working surface of the lower mold, and there is a cavity 7 consistent with half bucket teeth between the two flash grooves of the lower mold, and the forging block is fixed by screws 8 between the two flash grooves of the upper mold. 9. After forging, two identical half-side bucket tooth blanks are respectively processed with grooves at the welding position, and then welded into one bucket tooth. The slit 3 is located along the longitudinal width symmetrical plane of the bucket tooth.

Embodiment 3

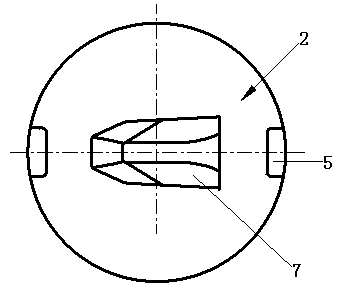

[0047] Embodiment 3, slitting is performed perpendicular to the long axis of the bucket teeth.

[0048] exist Figure 10-15 Among them, this set of molds includes sub-die 1 and sub-mold 2, sub-mold 1 forging the tooth tip part of the bucket teeth, sub-mold 2 forging the tooth root part of the bucket teeth, sub-mold 1 including upper die 1 and lower die 2, and upper die 1 There are guide blocks 4 on the two opposite sides, the two opposite sides of the lower mold 2 have guide grooves 5 corresponding to the guide blocks, and the working surfaces of the upper and lower molds have cavities 7 that are consistent with the tooth tips of the bucket teeth; The second also includes the upper die 1 and the lower die 2, the upper die has guide blocks 4 on both sides, the lower die has guide grooves 5 corresponding to the guide blocks, and the middle part of the working surface of the lower die has bucket tooth roots The same cavity 7; the middle part of the working surface of the upper d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com