Smelting method of platinum-rhodium thermocouple wire

A technology of dual wire and platinum-rhodium, which is applied in the field of smelting platinum-rhodium dual wire, can solve problems such as inaccurate temperature measurement and decreased yield, and achieve the effects of high yield, uniform composition, and accurate temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

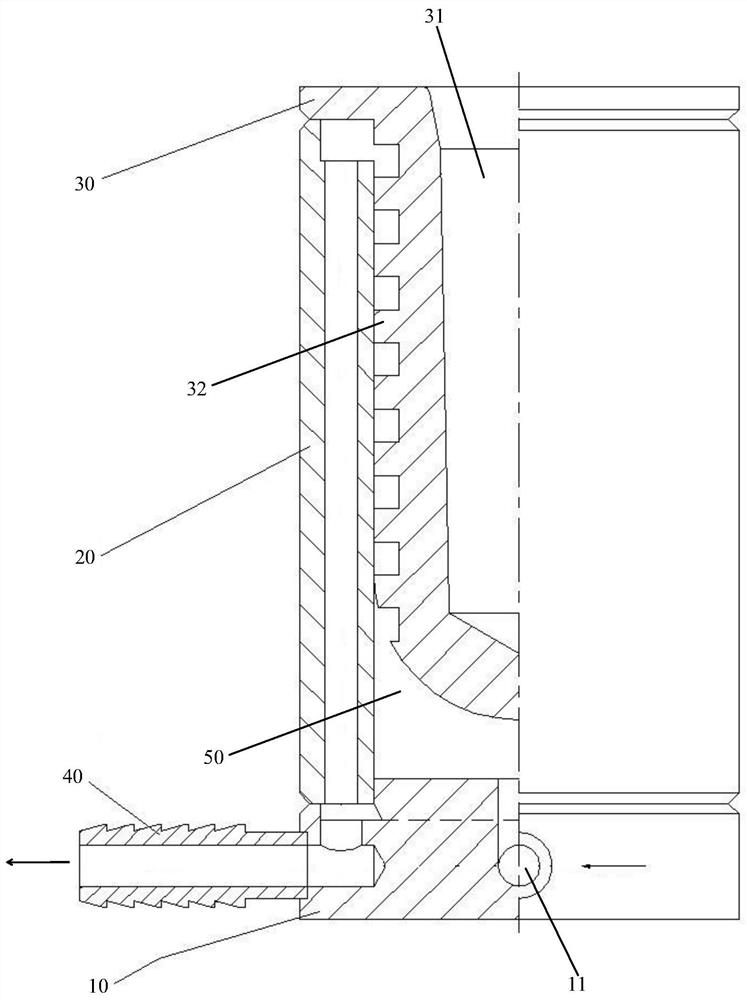

Method used

Image

Examples

Embodiment 1

[0026] The smelting method of platinum-rhodium 6 thermocouple wire comprises the following steps:

[0027] Step 1, sintering: put 120g of rhodium sponge with a purity greater than 99.95% into a calcia-stabilized zirconia crucible of a high-frequency induction melting furnace for sintering, the sintering temperature is 1100°C, the sintering time is 20min, and the sintering process is 2L / min flow into the oxygen.

[0028] Step 2, melting: after the sintering, stop the supply of oxygen, add 1880g of platinum block with a purity greater than 99.99%, raise the temperature to 2000°C, and melt all the materials into an alloy solution.

[0029] Step 3, Exhaust: After all the materials are melted, gradually lower the temperature to 1400°C, let the alloy solution slowly cool and solidify, keep the solidified state for 40s, then raise the temperature to 2000°C to re-melt, this process is repeated 6 times, during the exhaust process 0.01L / min of pure oxygen and 4L / min of argon are introd...

Embodiment 2

[0036] The smelting method of platinum-rhodium 10 thermocouple wire comprises the following steps:

[0037] Step 1, sintering: put 200g of rhodium sponge with a purity greater than 99.95% into a calcia-stabilized zirconia crucible of a high-frequency induction melting furnace for sintering, the sintering temperature is 1000°C, the sintering time is 30min, and 2.5L / Oxygen is introduced at a flow rate of min.

[0038] Step 2, melting: after the sintering, stop the supply of oxygen, add 1800g of platinum block with a purity greater than 99.99%, raise the temperature to 1900°C, and melt all the materials into an alloy solution.

[0039] Step 3, Exhaust: After all the materials are melted, gradually lower the temperature to 1300°C, let the alloy solution slowly cool and solidify, keep the solidified state for 40s, then raise the temperature to 1900°C to re-melt, this process is repeated 5 times, during the exhaust process 0.05L / min of pure oxygen and 4L / min of argon are introduce...

Embodiment 3

[0046] Step 1, sintering: Put 260g of rhodium sponge with a purity greater than 99.95% into a high-frequency induction melting furnace yttria-stabilized zirconia crucible for sintering, the sintering temperature is 1300°C, the sintering time is 30min, and the sintering process is 3L / min flow into the oxygen.

[0047] Step 2, melting: after the sintering, stop the supply of oxygen, add 1740g of platinum ingot with a purity greater than 99.99%, raise the temperature to 2300°C, and melt all the materials into an alloy solution.

[0048] Step 3, Exhaust: After all the materials are melted, gradually lower the temperature to 1400°C, let the alloy solution slowly cool and solidify, keep the solidified state for 40s, then raise the temperature to 2300°C to re-melt, repeat this process 3 times, during the exhaust process 0.1L / min of pure oxygen and 4.5L / min of argon are introduced throughout the process;

[0049] Step 4, refining: after exhausting, stop the supply of oxygen and argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com