Three-roller machine for producing epoxy zinc-rich primers

An epoxy zinc-rich primer and three-roll machine technology, which is applied in the direction of layered products, metal layered products, lamination, etc., can solve environmental pollution, do not meet low-carbon economy, and performance indicators do not meet quality requirements, etc. problem, to achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

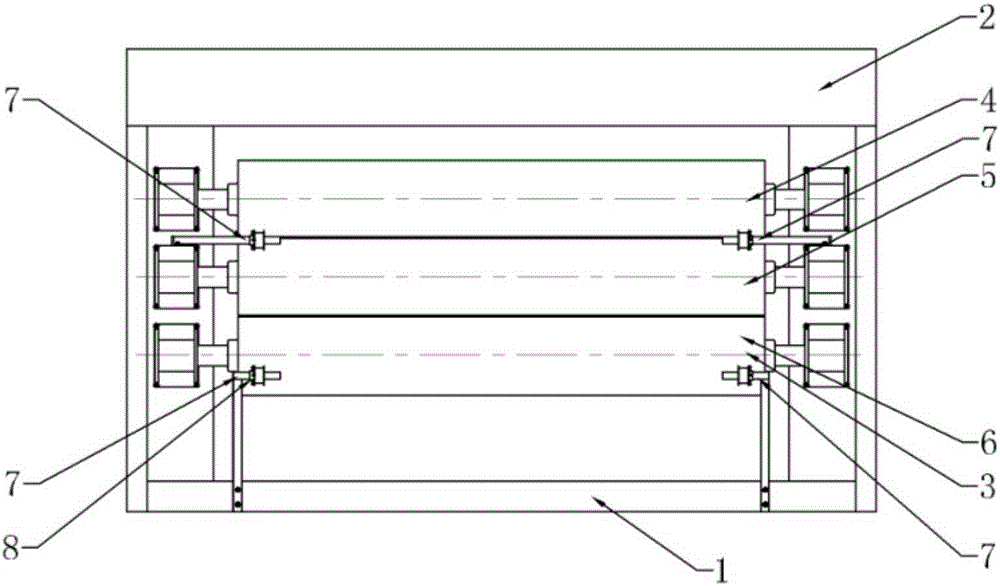

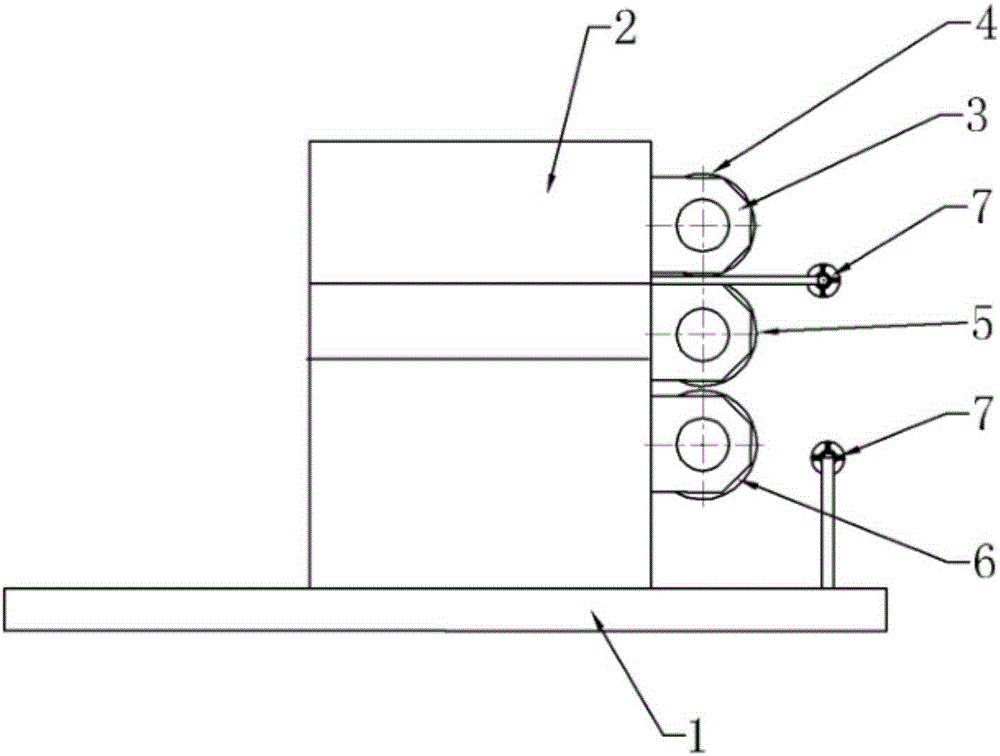

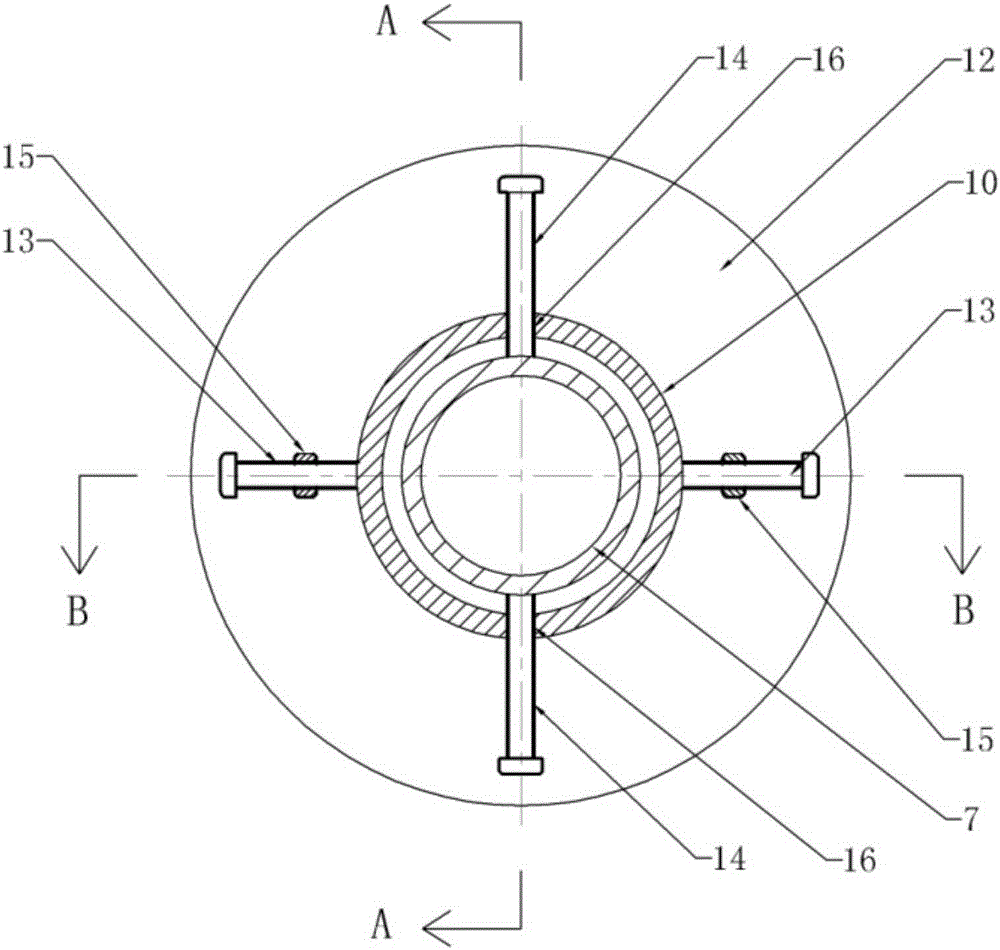

[0017] Such as figure 1 , figure 2 Shown, a kind of three-roller machine that is used to produce epoxy zinc-rich primer of the present invention comprises base 1, roll frame 2 and pressing roll 3, and pressing roll 3 comprises upper roll 4, middle roll 5 and lower roll 6, and they from Arranged in order from top to bottom, and the axes are parallel to each other, the upper roller 4, the middle roller 5 and the lower roller 6 are all installed on the roller frame 2 through the bearing housing, and they are driven by the electric motor. The present invention also includes four positioning shafts 7, the axis of each positioning shaft 7 is parallel to the axis of the lower roller 6, the four positioning shafts 7 are divided into upper and lower groups, and each group of positioning shafts 7 is located on the front side of the lower roller 6, The upper set of positioning shafts 7 is fixedly installed on the roller frame 2 through connecting rods, the lower set of positioning shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com