Process for recovering androstenedione from androstenedione fermentation waste liquid

A technology of androstenedione and fermentation waste liquid, which is applied in the direction of steroids and organic chemistry, can solve the problems that fermentation waste liquid is easy to pollute the environment and occupy the space of factories and enterprises, and achieve efficient recovery and waste recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

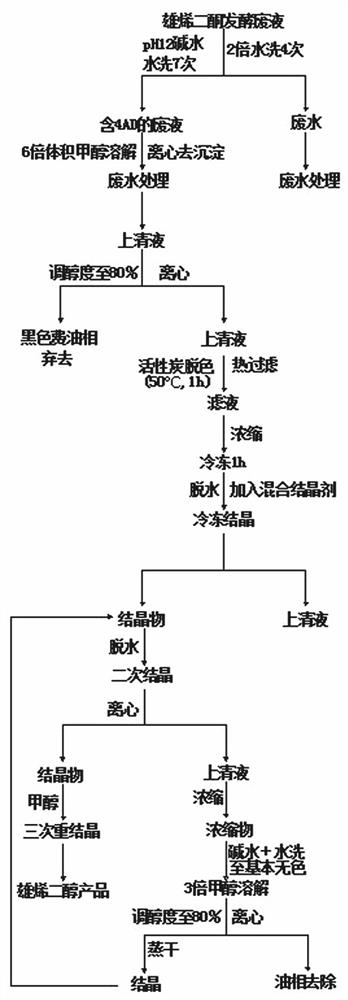

Method used

Image

Examples

Embodiment 1

[0035] The processing method of androstenedione fermentation waste liquid, the steps are as follows:

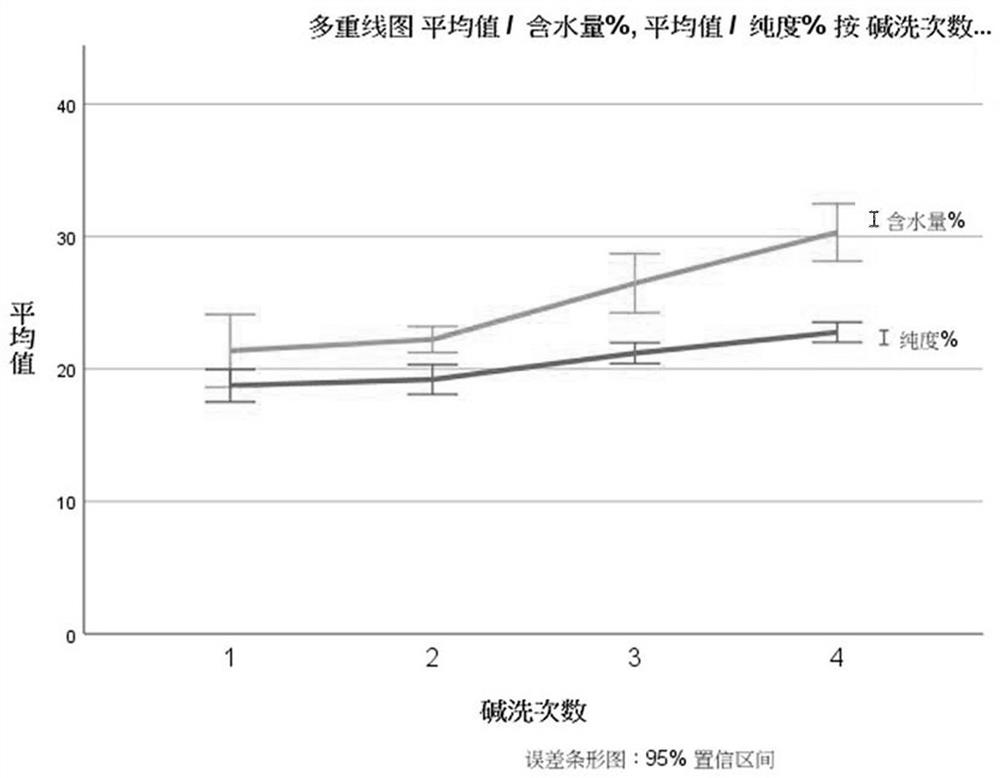

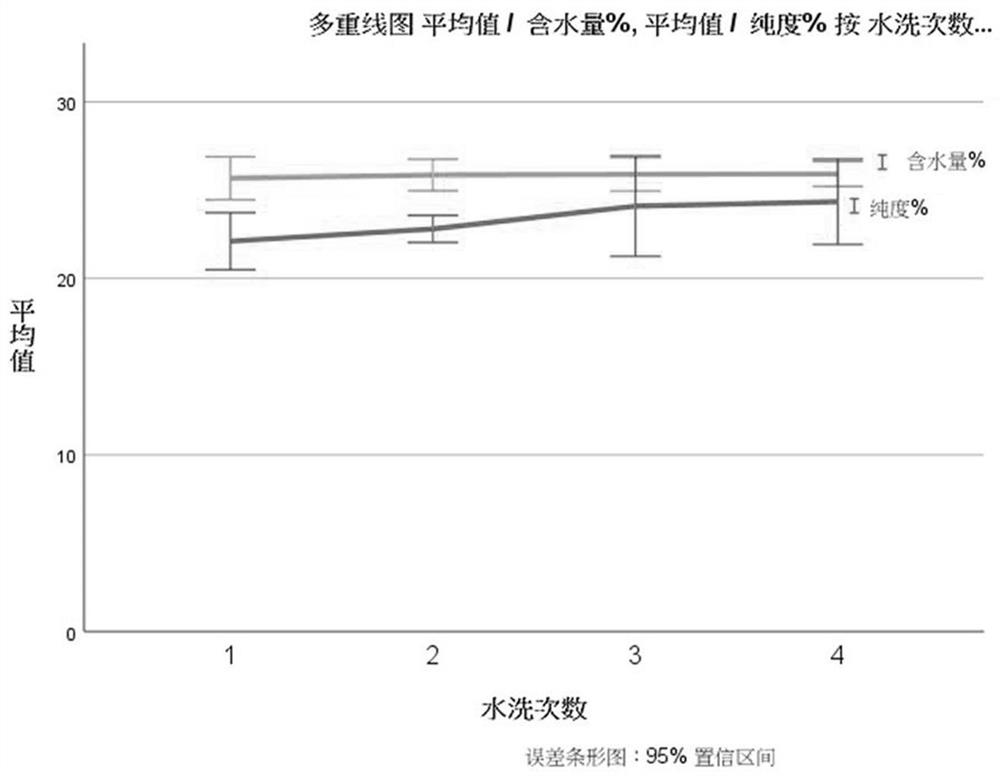

[0036] 1) Add lye with pH 12 to the androstenedione fermentation waste liquid according to the material-to-liquid ratio of 1:2, and at 40-50°C, sonicate for 5 minutes, wash 5-7 times, then add water to wash 3-5 times, wash Until the solution is basically transparent;

[0037] 2) Add 6-10 times methanol to the washed sample, ultrasonicate for 5 min at 40-50°C, dissolve thoroughly, and centrifuge at 4000-6000rpm to remove the precipitate;

[0038] 3) Adjust the concentration of methanol in the supernatant to 78-80%, and centrifuge to remove the black oil;

[0039] 4) Add 5% of the sample weight to the supernatant with activated carbon for decolorization for 1 hour, filter, and rotate to evaporate to 20% water, freeze for 1 hour, pour off the water phase, and continue to concentrate to anhydrous;

[0040] 5) Add 1-1.5 times of ethyl acetate to dissolve, then add 0.5-0.7 times ...

Embodiment 2

[0043] 1) Take 200 grams of androstenedione fermentation waste liquid, add 400 mL of lye solution with pH 12 to the androstenedione fermentation waste liquid, and wash it 7 times by ultrasonication for 5 min at 40~50 °C, and then wash with water for 400 °C Wash 4 times with mL until the solution is basically transparent;

[0044] 2) Add about 120-150 grams of the washed sample into 720 mL of methanol, sonicate for 5 minutes at 40-50 ℃, dissolve thoroughly, and centrifuge at 6000 rpm to remove the precipitate;

[0045] 3) Add about 700 mL of supernatant to 175 mL of water to adjust the concentration of methanol to 80%, and centrifuge to remove the black oil;

[0046] 4) Add 5 g of activated carbon to the supernatant to decolorize the sample weight (100 g), shake on a shaker at 50 ° C for 1 hour, filter, and rotate to evaporate to 20% water content, freeze for 1 hour, pour off the water phase, and continue to concentrate to nothing. water, about 60 grams;

[0047] 5) Add 90 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com