Salting extractant and separating method for extracting and rectifying m-methylethylbenzene and p-methylethylbenzene from C9 mixture

A p-toluene, extraction and rectification technology, applied in the direction of distillation purification/separation, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

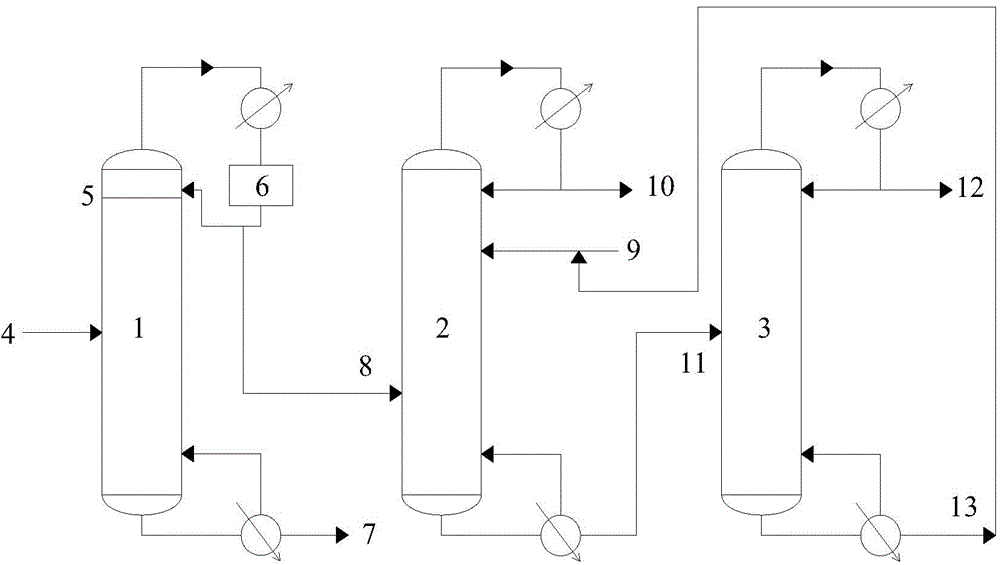

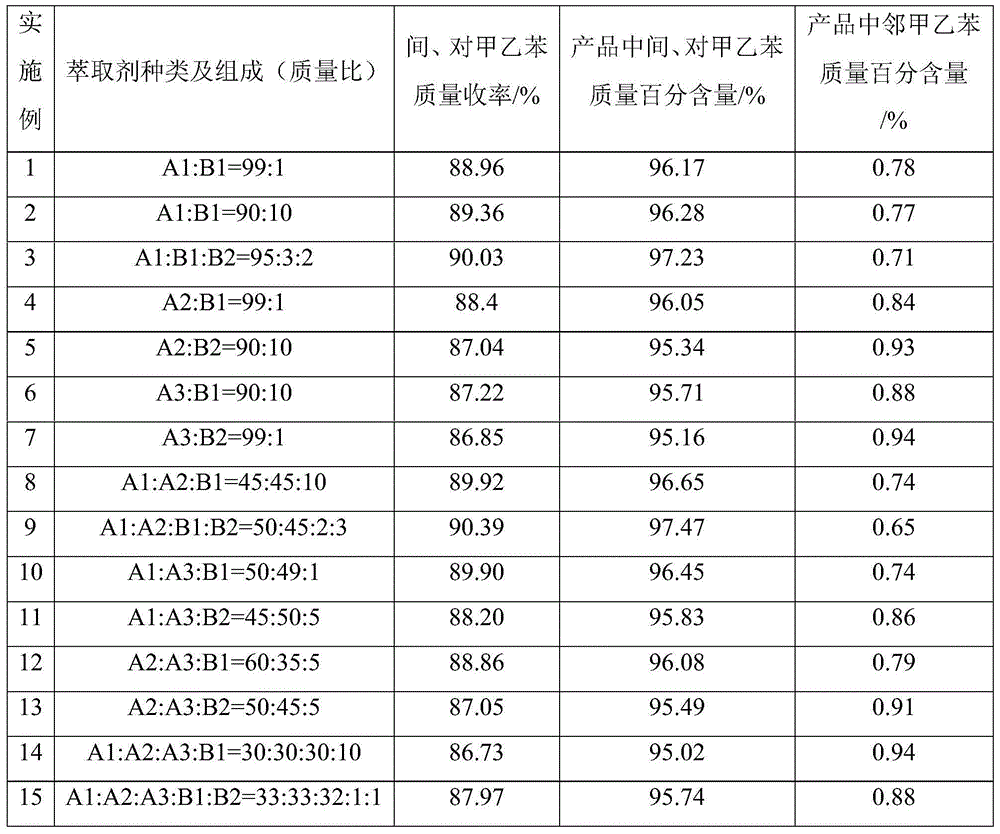

[0026] refer to figure 1 The flow shown, from C 9 Separation of m- and p-methylethylbenzene from aromatic hydrocarbon mixture. with C 9 Total mass of aromatic mixture, C 9 Aromatic mixture, C 9 The mass percentage of the former component is 1.06%, the total mass percentage of m-methylethylbenzene and p-methylethylbenzene is 82.80%, and the total mass percentage of mesitylene and o-methylethylbenzene is 1.57%. The salt-added extractant is selected from 99 parts by mass of methyl salicylate and 1 part by mass of potassium thiocyanate. The total mass of salted extractant and C 9 The ratio of the total mass of the aromatic mixture is 0.5. The number of theoretical plates of the heavy component removal tower is 20, and the reflux ratio based on mass is 1; the number of theoretical plates of the extractive distillation column is 60, and the reflux ratio based on mass is 2; The calculated reflux ratio is 1; the top pressure of each tower is 0.1MPa. The yield of the obtained p...

Embodiment 2

[0028] refer to figure 1 The flow shown, from C 9 Separation of m- and p-methylethylbenzene from aromatic hydrocarbon mixture. with C 9 Total mass of aromatic mixture, C 9 Aromatic mixture, C9 The mass percentage of the former component is 1.06%, the total mass percentage of m-methylethylbenzene and p-methylethylbenzene is 82.80%, and the total mass percentage of mesitylene and o-methylethylbenzene is 1.57%. The salt-added extractant is selected from 90 parts by mass of methyl salicylate and 10 parts by mass of potassium thiocyanate. The total mass of salted extractant and C 9 The ratio of the total mass of the aromatic mixture is 0.5. The number of theoretical plates of the heavy component removal tower is 20, and the reflux ratio based on mass is 1; the number of theoretical plates of the extractive distillation column is 60, and the reflux ratio based on mass is 2; The calculated reflux ratio is 1; the top pressure of each tower is 0.1MPa. The yield of the obtained p...

Embodiment 3

[0030] refer to figure 1 The flow shown, from C 9 Separation of m- and p-methylethylbenzene from aromatic hydrocarbon mixture. with C 9 Total mass of aromatic mixture, C 9 Aromatic mixture, C 9 The mass percentage of the former component is 1.06%, the total mass percentage of m-methylethylbenzene and p-methylethylbenzene is 82.80%, and the total mass percentage of mesitylene and o-methylethylbenzene is 1.57%. The salt-added extractant is selected from 95 parts by mass of methyl salicylate, 3 parts by mass of potassium thiocyanate and 2 parts by mass of sodium thiocyanate. The total mass of salted extractant and C 9 The ratio of the total mass of the aromatic mixture is 0.5. The number of theoretical plates of the heavy component removal tower is 20, and the reflux ratio based on mass is 1; the number of theoretical plates of the extractive distillation column is 60, and the reflux ratio based on mass is 2; The calculated reflux ratio is 1; the top pressure of each tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com