Method for fast separating fast-moving heparin and dermatan sulfate

A dermatan sulfate, fast-moving technology, applied in the field of separation of mucopolysaccharide components in heparin anticoagulant drugs, can solve problems such as long electrophoresis time and band dispersion, and achieve the effect of reducing electrophoresis voltage and prolonging electrophoresis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

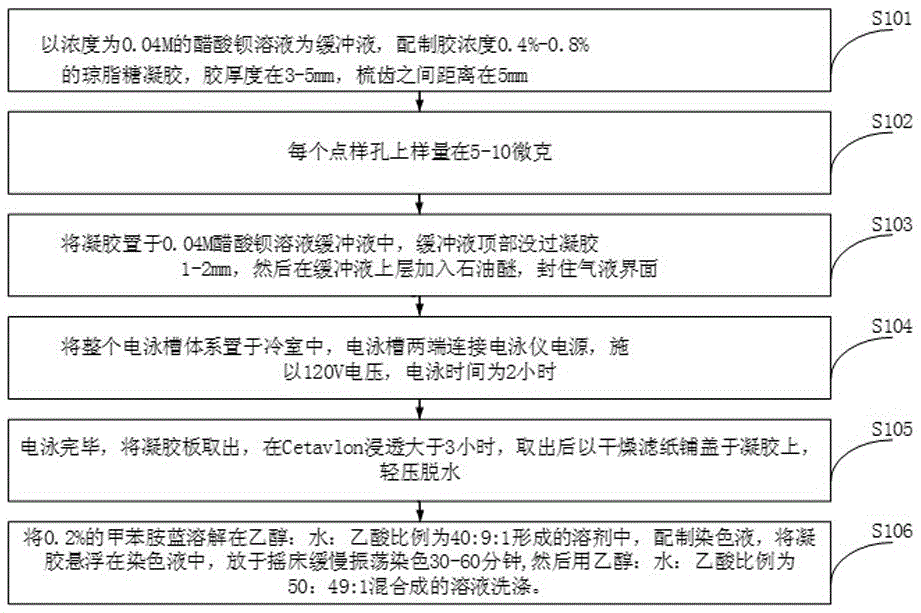

[0050] Preparation of agarose gel: The specification of the electrophoresis gel is 100×70, the concentration is 0.6%, the buffer solution is 0.04M barium acetate (PH5.8), the thickness of the electrophoresis gel is 3mm, the agarose is melted in the buffer solution and cooled to 60 At about ℃, pour it into the glue tank and wait for it to solidify before use;

[0051] Electrophoresis: put the solidified gel in the electrophoresis tank, use 0.04M barium acetate (pH5.8) as the buffer, load 10 micrograms of sample on each gel well, and slowly add a small amount to the top of the buffer after loading the sample Petroleum ether, put the whole set of electrophoresis equipment in a 4°C cold room, 120V, electrophoresis for 2 hours;

[0052] Staining and decolorization: After electrophoresis, take out the gel plate, soak it in Cetavlon solution for 3 hours, cover it with dry filter paper after taking it out, dehydrate it several times with careful pressure; use toluidine blue solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com