Urea injection system for boat and injection method of urea injection system

A urea injection system and urea technology, applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of large fluctuations in the pressure of urea solution, affecting the stable operation of the urea injection system, immature and popularization of marine SCR system technology, etc. , achieve huge economic benefits, good social benefits, reduce environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

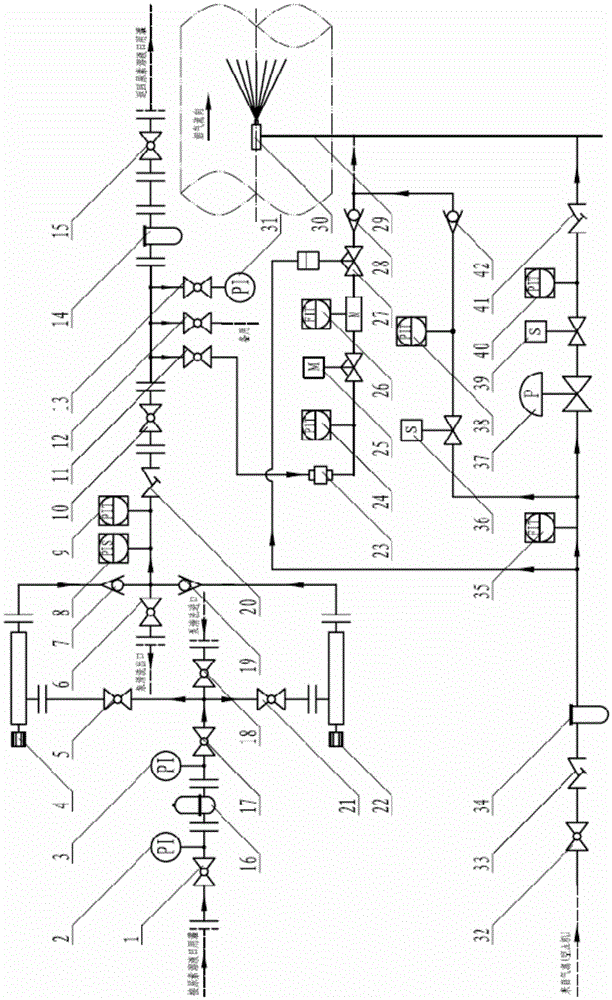

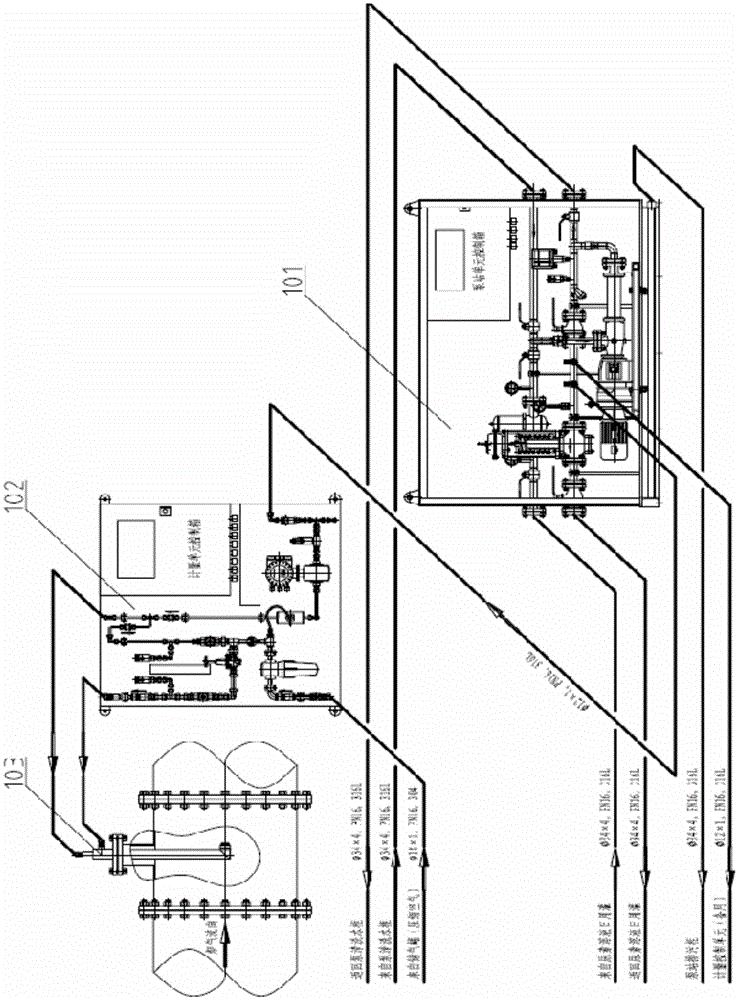

[0036] A marine urea injection system in this embodiment includes a pump station, a urea solution pressure control unit 101 , a metering control unit 102 , and a nozzle spray gun unit 103 . The pump station and the urea solution pressure control unit are made into a skid-mounted overall structure, such as figure 2 shown.

[0037] like figure 1 As shown, the pump station unit includes a first ball valve 1, a first pressure gauge 2, a first filter 16, a second pressure gauge 3, and a second ball valve 17 connected in sequence; the outlet of the second ball valve 17 is connected in parallel to the third ball valve 5 And the fourth ball valve 21; the outlet of the third ball valve 5 is connected with the first single screw pump 4; the outlet of the first single screw pump 4 is connected with the fifth ball valve 6 after connecting the first check valve 7; the outlet of the fifth ball valve 6 is connected Pump cleaning fluid pipeline; the outlet of the fourth ball valve 21 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com