Method of Determining Engineering Stable Machining Process Parameter Diagram Based on Two-Dimensional Flutter Stability Limit Diagram

A technology with processing technology and stability limit, which is used in the selection of high-speed and high-efficiency milling parameters, can solve problems such as shortening the trial production cycle, and achieve the effect of shortening the trial production cycle and improving the overall processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

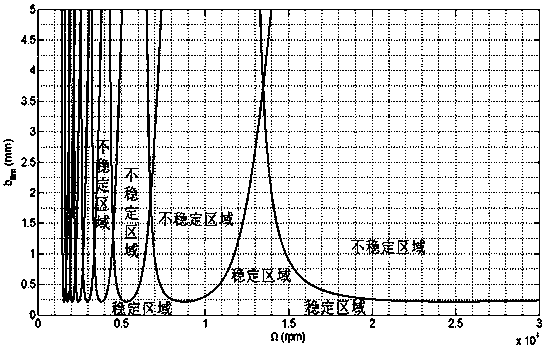

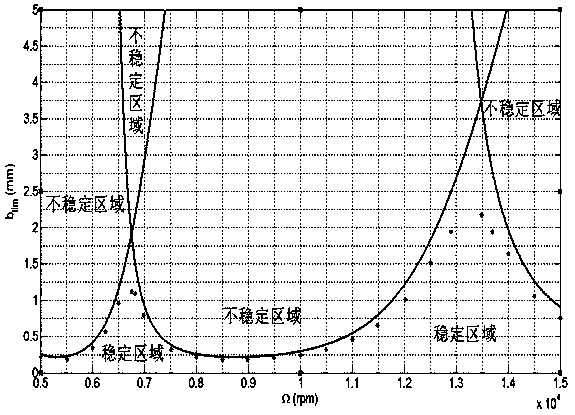

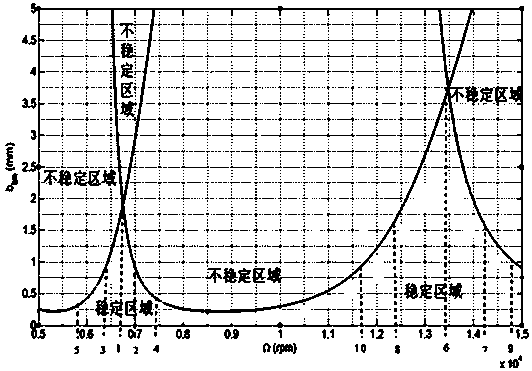

[0031] A method for determining a stable machining process parameter diagram for engineering based on a two-dimensional flutter stability limit diagram. This method is based on the two-dimensional flutter stability mechanical expression equation and limit diagram in the milling processing system, and is applied in the application range where the spindle speed of the processing equipment is 5000-15000rpm Inside, the depth of cut of the spindle speed in different ranges is corrected and the curve is smoothed according to the degree of membership value to obtain the stable machining mechanics expression equation and process parameter diagram for engineering. This method is realized by the following steps:

[0032] Step 1. Based on the process system composed of similar workpieces and fixtures that are prone to flutter and the processing system composed of tool spindles, the modal parameters of the process system, modal parameters of the processing system, and the vibration shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com