Dipping soldering lug cold heading forming equipment

A forming equipment and cold pier technology, applied in the field of machinery, can solve the problems of complex forming equipment, cumbersome control, and high precision requirements, and achieve the effects of reducing labor costs and equipment costs, compact and reliable structure, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

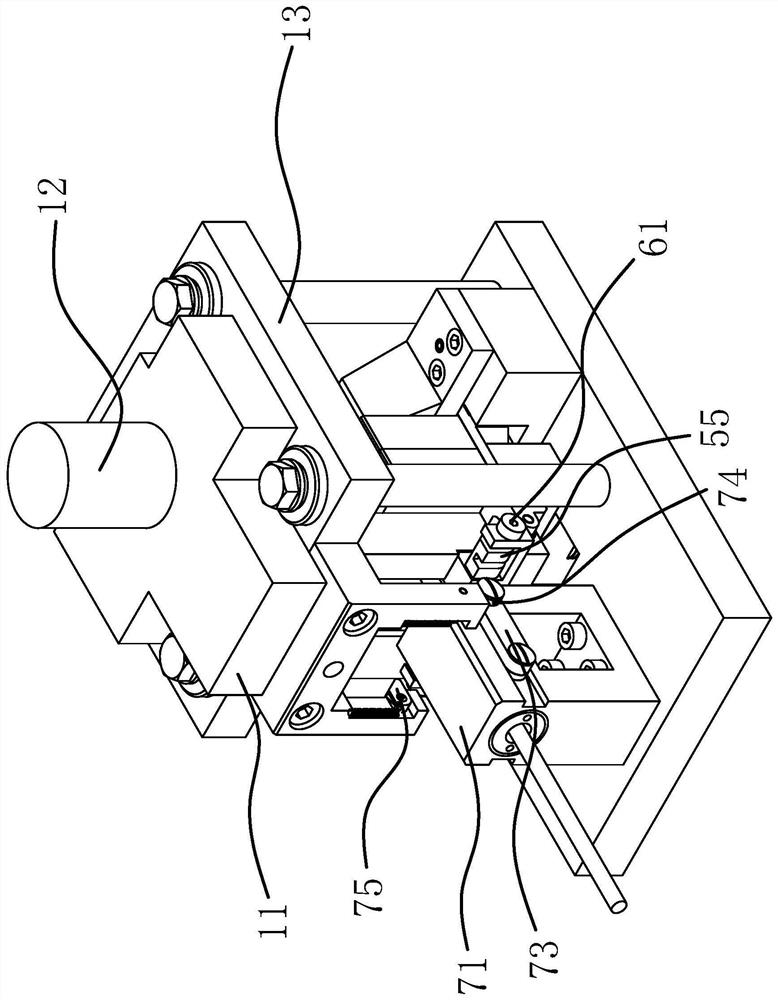

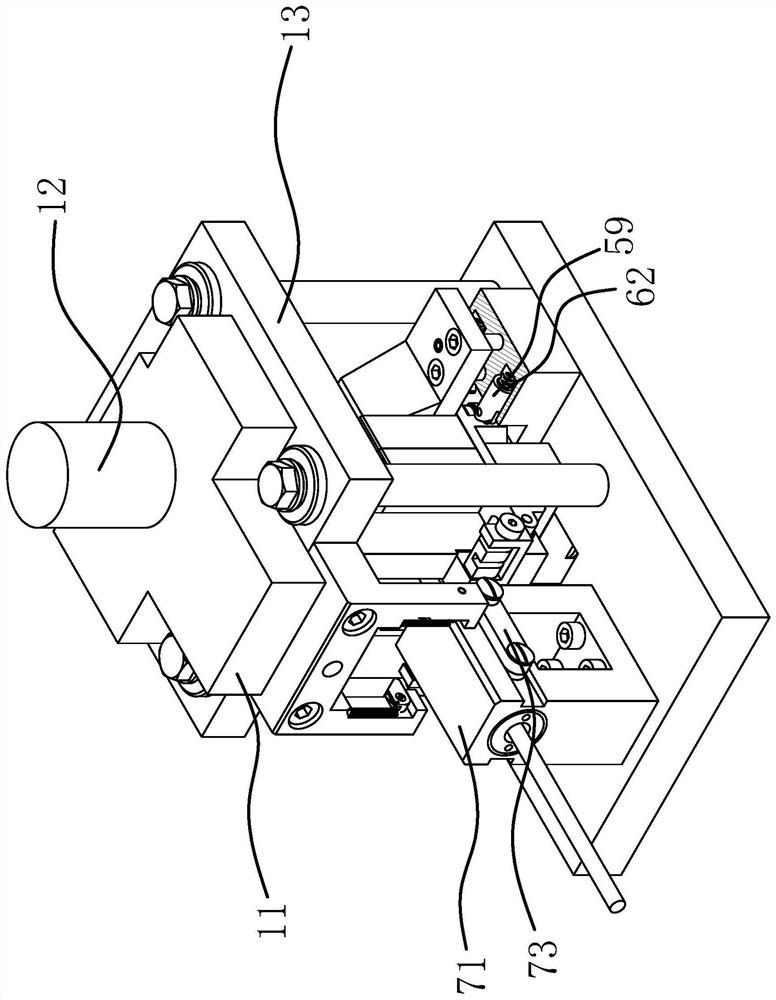

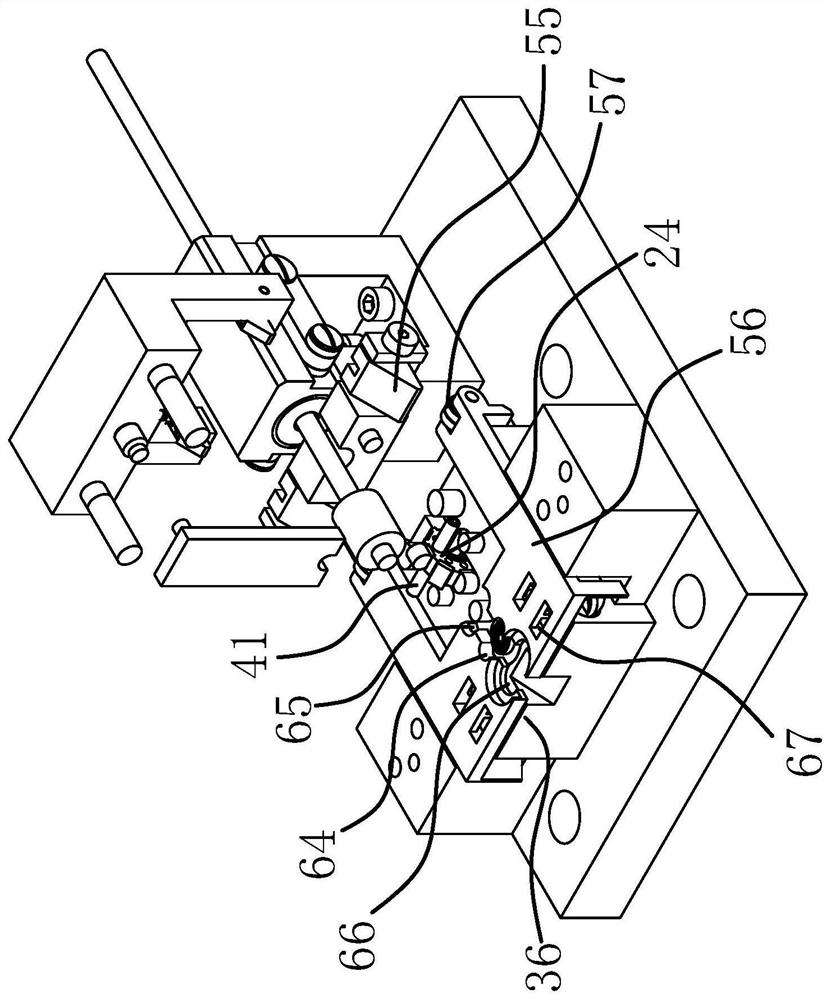

[0041] like Figure 1 to Figure 14 As shown, the cold pier forming equipment includes a fuselage 11, a hydraulic cylinder 12, a raw material feeding mechanism, a cutting mechanism, a feeding and unloading mechanism and a pier pressing forming mechanism. The cylinder body of the hydraulic cylinder 12 is fixed on the fuselage 11, and the hydraulic cylinder A linkage plate 13 is fixedly arranged on the push rod of 12. The raw material feeding mechanism includes a feeding guide hole 21 for inserting strip-shaped raw materials. The linkage plate 13 is fixedly provided with a cutting head 23 inserted in the cutting trough 22, and the feeding and discharging mechanism includes a runner 24 which is rotatably connected to the fusel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com