Nanosilicon thin-film multi-junction solar cell

A technology for solar cells and nano-silicon thin films, applied in the field of solar cells, can solve the problems of low open-circuit voltage and filling factor, large light-induced attenuation, and low conversion efficiency of nano-silicon solar cells, so as to avoid interface effects and reduce light-induced degradation. effect, the effect of improving the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

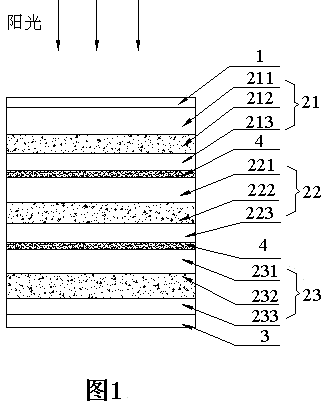

[0022] see figure 1 , the nano-silicon thin film double-junction solar cell of the present invention comprises a positive electrode layer 1 and a negative electrode layer 3, and three P-I-N junctions (subcells) 21, 22 and 23 are arranged between the positive electrode layer 1 and the negative electrode layer 3 as photoelectric In the conversion layer, the P-I-N junction 21 is the top cell, and the P-I-N junction 23 is the bottom cell. The P-I-N junction 21 is composed of a P-type silicon film layer 211, an intrinsic silicon film absorbing layer 212 and an N-type silicon film layer 213, and the P-I-N junction 22 is composed of a P-type silicon film layer 221, an intrinsic silicon film absorbing layer 222 and an N-type silicon film layer. The silicon thin film layer 223 is stacked in sequence, and the P-I-N junction 23 is composed of a P-type silicon thin film layer 231, an intrinsic silicon thin film absorption layer 232 and an N-type silicon thin film layer 233. Coupling laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com