Diode pumped solid state laser (DPL) and debugging method therefor

A laser, all-solid-state technology, applied in the laser field, can solve problems such as unfavorable compression of divergence angle, unfavorable laser imaging, good beam quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

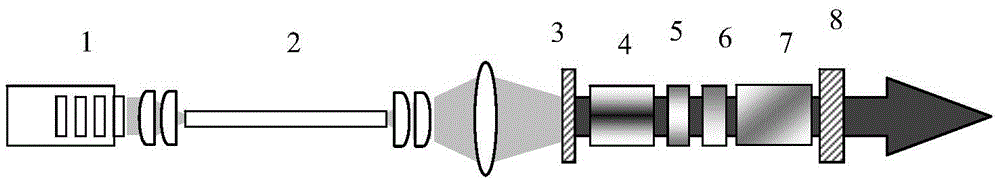

[0041] Such as figure 1 , 2 As shown, the present embodiment relates to an all-solid-state laser, which is a high-beam quality, non-water-cooled all-solid-state laser, including:

[0042] Semiconductor pumping source 1, used to provide quasi-continuous pumping light with high peak power;

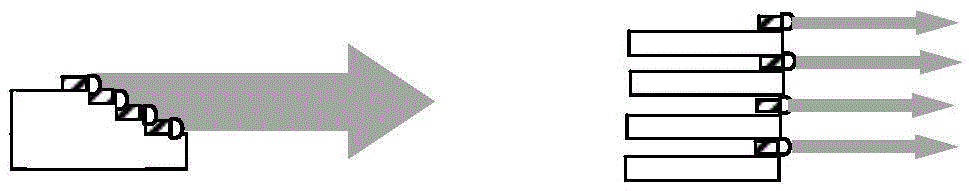

[0043] The coupling system 2 is used to transmit and homogenize the quasi-continuous pump light with high peak power, and couple the pump light into the laser crystal 4;

[0044] Laser crystal 4, providing gain;

[0045] Two-color plano-convex cylindrical total reflection mirror 3, used to transmit pump light and reflect laser light;

[0046] Polarizer 5 to polarize the laser light;

[0047] Quarter-wave plate 6, through which the polarization direction of the laser is rotated by 45°;

[0048] Pockels cell 7, control the voltage applied thereon, so that when no voltage is applied to the Pockels cell, it corresponds to a flat sheet, and when a quarter voltage is applied to the Pockels ce...

Embodiment approach 2

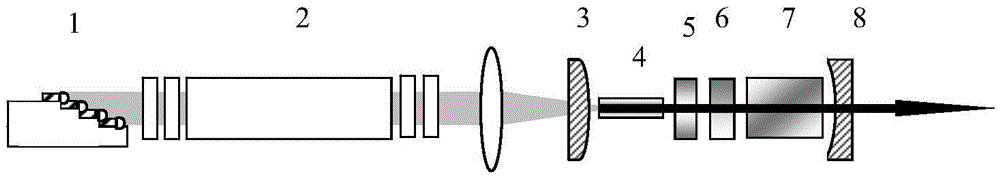

[0060] Such as Figure 5 , 6 As shown, this embodiment relates to an all-solid-state laser, which is a water-cooled all-solid-state passive Q-switched laser with high beam quality, including:

[0061] Semiconductor pumping source 1, coupling system 2, two-color plano-concave cylindrical total reflection mirror 3, laser crystal 4, Cr4+:YAG passive Q-switching crystal 9, plano-concave cylindrical output mirror 6. The semiconductor pumping source 1, the coupling system 2, the two-color plano-concave cylindrical total reflection mirror 3 and the laser crystal 4 are the same as those in Embodiment 1, and will not be described in detail in this embodiment.

[0062] Cr4+: YAG passive Q-switching crystal 9 with an initial transmittance of 30% and a thickness of 4mm. The transmittance of 6 plano-concave cylindrical output mirrors to 1064nm is 60%. Two-color plano-convex cylindrical mirror 3 and plano-concave cylindrical output mirror 6 The resonant cavity formed is 10cm long. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com