A macro-channel liquid-cooled high-power semiconductor laser module and device

A laser and macro channel technology, applied in semiconductor lasers, lasers, laser parts, etc., can solve problems such as the expansion of the number of bars that are difficult to assemble and spliced, the lack of overall strength and rigidity of the heat sink, and the impact on the quality of the package. Good structure, improved heat dissipation effect, convenient mechanical assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

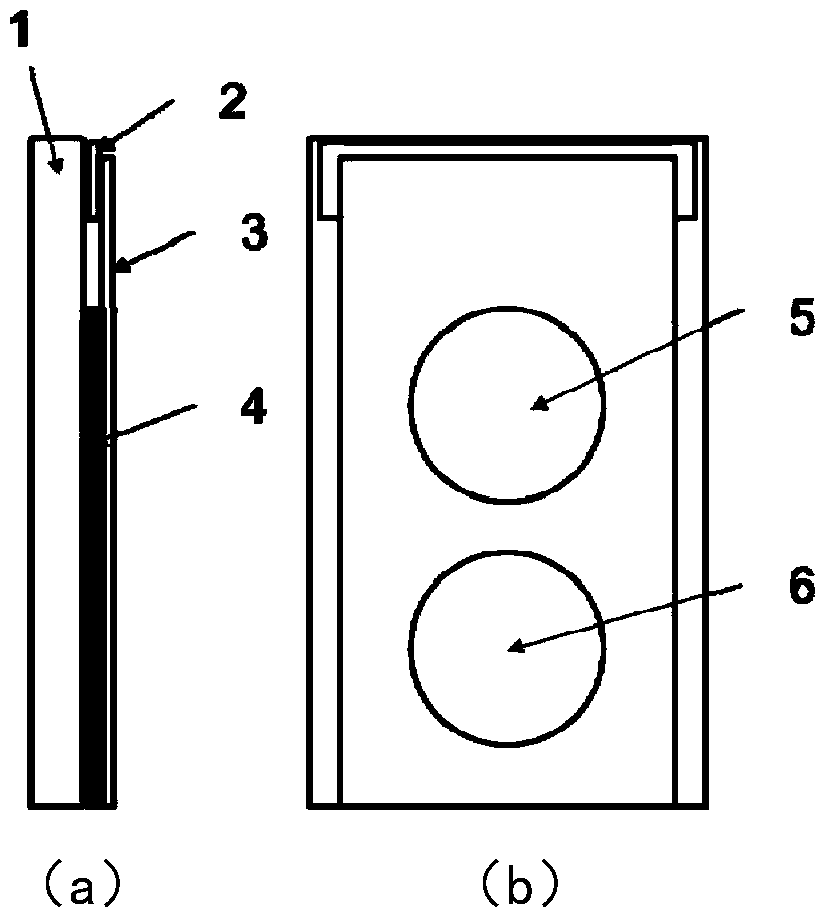

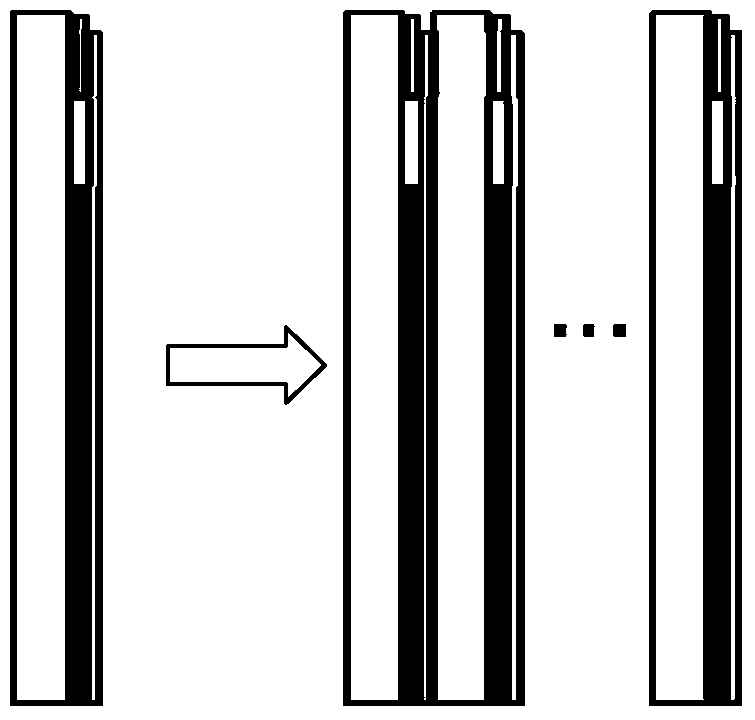

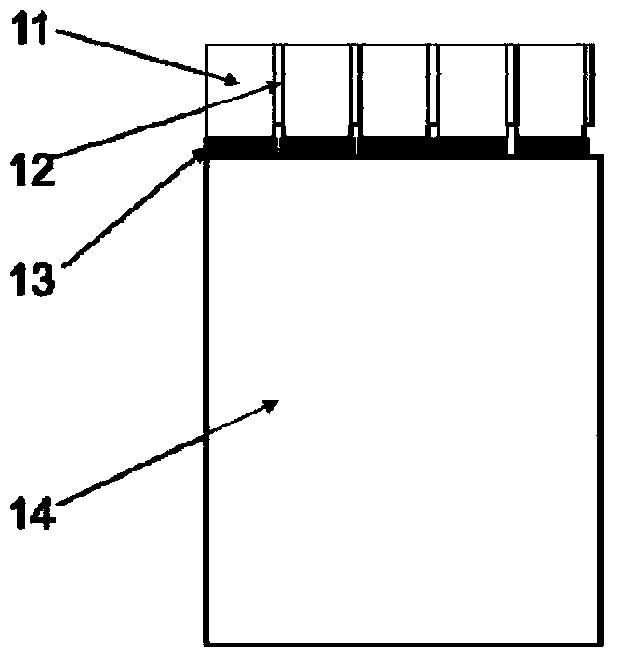

[0039] Such as image 3 , 4 As shown, the laser chip 12 is assembled on a substrate 11 of a conductive material with high thermal conductivity and CTE matching, and the substrate material is a diamond-copper alloy. The substrate mounted with the laser chip is assembled to the heat sink 14 through the insulating block 13 with high thermal conductivity to form a laser module. A water inlet and a water outlet parallel to each other are opened through the side of the heat sink, and a liquid cooling circuit of a macro channel is arranged inside the heat sink. Multiple laser modules can be "seamlessly" connected through the sealing ring, share the water inlet 15 and the water outlet 16, and realize expansion, such as Figure 5 shown.

[0040] The heat sink is specifically composed of multi-layer water-passing plates, and the flow direction between adjacent two layers is opposite to achieve uniformity of heat dissipation on the laser mounting surface. The heat sink of the heat si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com