Squirrel-cage-shaped motor driven water injection pump load start pressure-stabilizing water injection apparatus

A squirrel-cage, water injection pump technology, applied in the direction of control of electromechanical transmission, control of generators, machines/engines, etc., can solve the problems of fluctuating return flow, water injection pump cannot start water injection pressure with load, etc., achieve small starting current, Realize the effect of starting with load and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

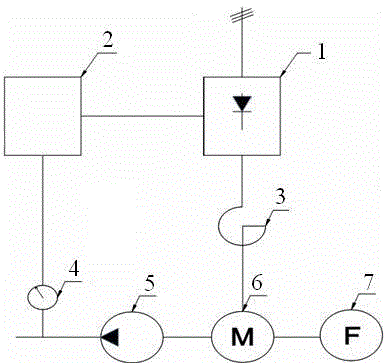

[0016] like figure 1 As shown, this embodiment provides a water injection pump driven by a squirrel-cage motor with load to start a stabilized water injection device, including a water injection pump 5, a squirrel-cage motor 6 that drives the water injection pump 5, and an intelligent vector frequency converter 1. Redundant pressure controller 2 and pressure sensor 4;

[0017] The intelligent vector frequency converter 1 is connected to the three-phase AC power supply, the pressure sensor 4 is arranged at the manifold end of the water injection pump 5, and the pressure sensor 4 feeds the pressure signal to the redundant pressure controller 2, and the redundant pressure controller 2 The received pressure signal and the frequency output of the intelligent vector inverter 1 form a closed-loop control, the intelligent vector inverter 1 is connected to the squirrel-cage motor 6, and the speed of the squirrel-cage motor 6 is changed through the output frequency of the intelligent ve...

Embodiment 2

[0021] On the basis of Embodiment 1, the intelligent vector frequency converter 1 is equipped with an output reactor 3, which increases the effective transmission distance from the frequency converter to the motor, effectively suppresses the instantaneous high voltage generated when the IGBT of the frequency converter switches, and reduces the impact of this voltage on Adverse effects on cable insulation and motors.

[0022] In this embodiment, the tail of the squirrel-cage motor 6 is provided with a strong cooling independent fan 7 to increase the exhaust air volume of the squirrel-cage motor 6 at low speed and reduce the temperature rise of the squirrel-cage motor 6 .

Embodiment 3

[0024] On the basis of Embodiment 2, the water injection pump driven by the squirrel-cage motor of the present invention is used to start the water injection device with load and start the water injection device with a power of 185kW. The water injection pump 5 driven by the squirrel-cage motor 6 (model 5DS-25.7 / 20 ) on the test run, the intelligent vector inverter 1 is connected to the three-phase AC power supply, and the intelligent vector inverter 1 controls the squirrel-cage motor 6 by connecting the output reactor 3, and the squirrel-cage motor 6 drives the water injection pump 5 to run. At 17MPa, the maximum starting current is 300A, which is less than the rated current of the motor, and the starting is relatively stable; when the target pressure is 18.5MPa, the fluctuation of the water injection pressure is less than 0.1MPa; after adding a strong cooling independent fan 7 at the tail of the motor, the temperature of the motor shell is reduced 5 ℃, completely eliminate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com