Double-core heating cable for electric floor heating

A heating cable, floor heating technology, applied in the direction of household heating, household heating, application, etc., can solve the problems of easy generation of plasticizer odor, hidden dangers, aging, etc., achieve excellent chemical stability, ensure safe use, electricity Good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

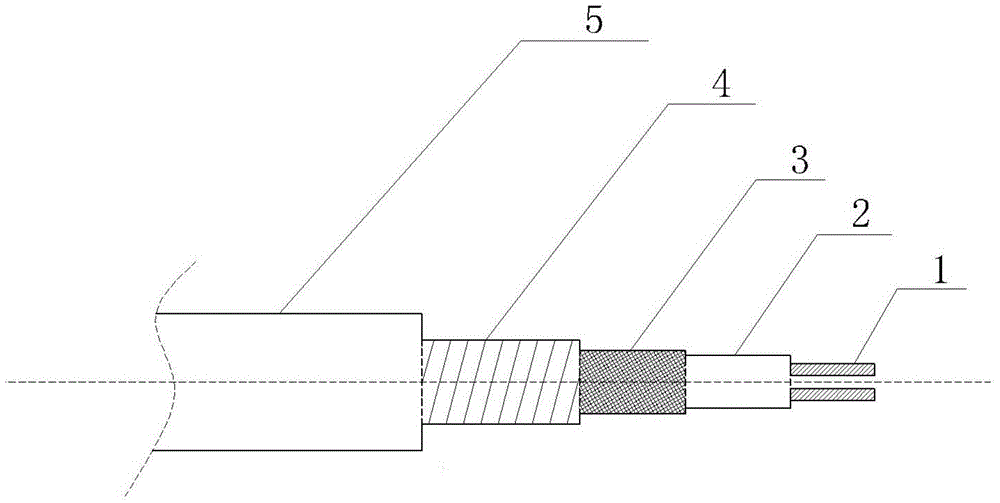

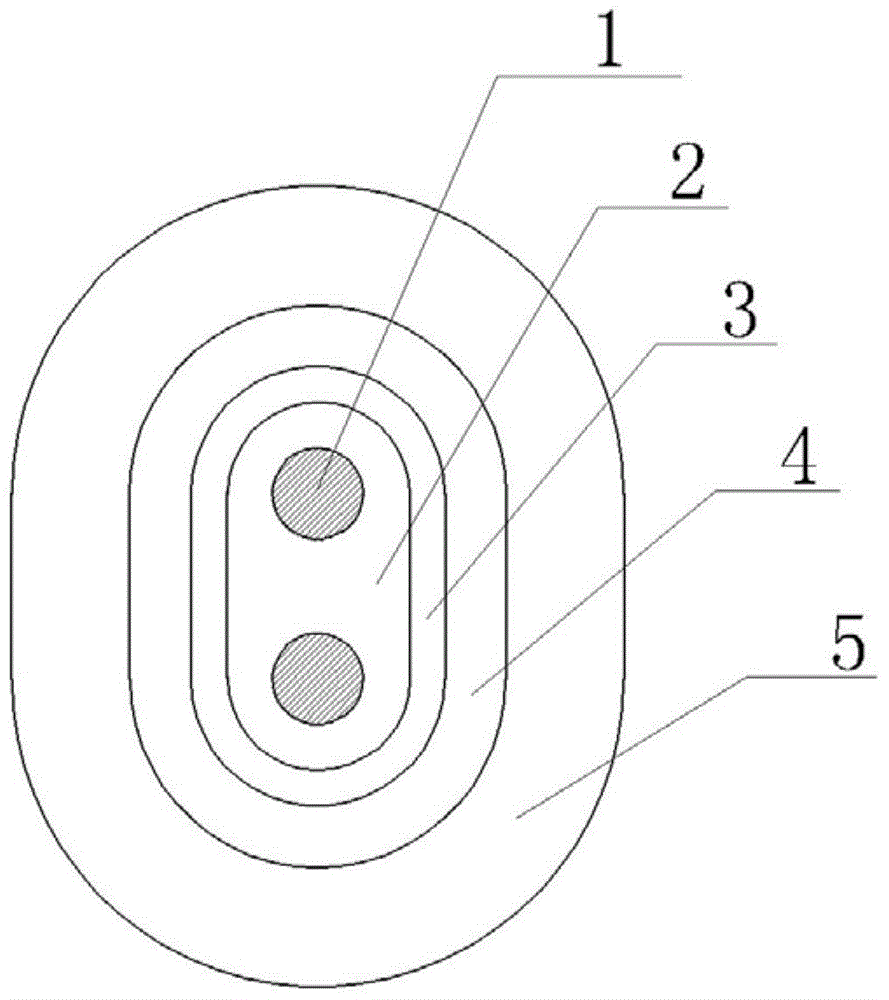

[0018] Such as figure 1 and figure 2 As shown, the double-core heating cable used for electric floor heating has an elliptical shape. The heating cable includes two alloy heating cores 1, insulating layer 2, grounding layer 3, shielding layer 4, outer protective sheath 5, and alloy heating core 1. Wrap the high-temperature resistant insulating layer 2, the grounding layer 3 is made of double-layer braided metal wires and wrapped on the insulating layer 2, the grounding layer 3 is provided with a shielding layer 4, the shielding layer 4 is divided into inner and outer layers, and the inner layer is composed of The outer layer is made of aluminum foil or metal wire braiding, and the outer layer is formed by winding the metal wire clockwise around the inner layer of the shielding layer 4 as the axis, and the shielding layer 4 is provided with a protective sheath 1 .

[0019] In this embodiment, the alloy heating core 1 is composed of two core wires of chromium-nickel alloy, cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com