Array substrate, radiation detector, and wiring substrate

A technology of array substrates and substrates, which is applied in the fields of array substrates, radiation detectors and wiring substrates, and can solve problems such as cost increase and equipment size expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

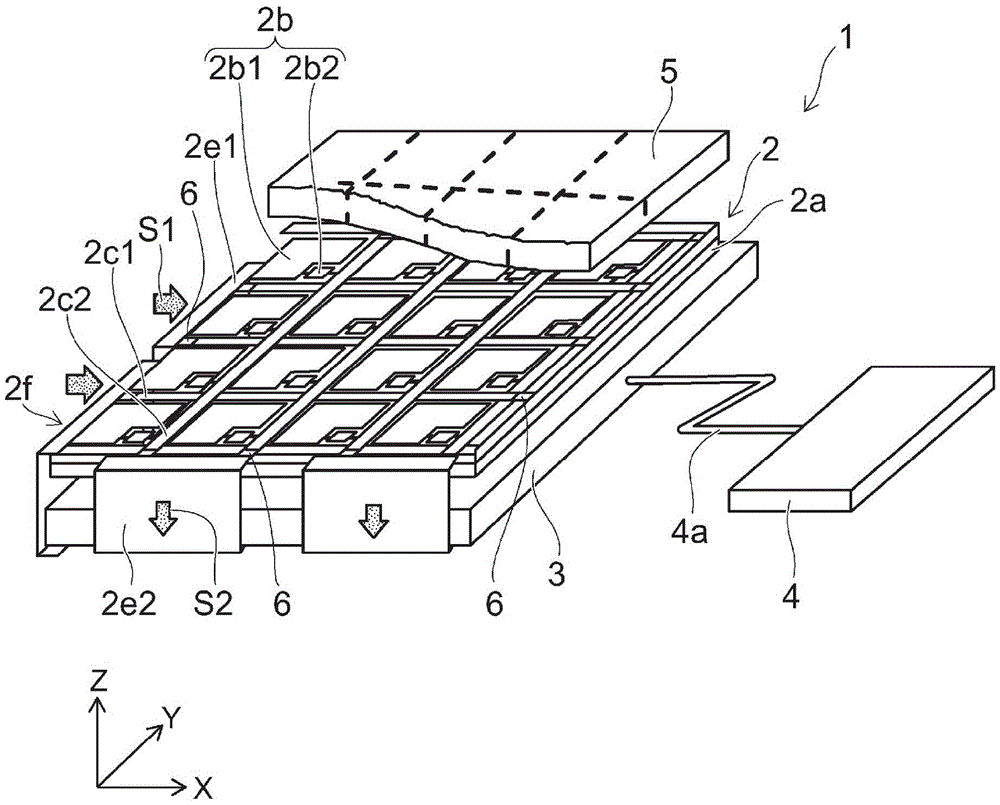

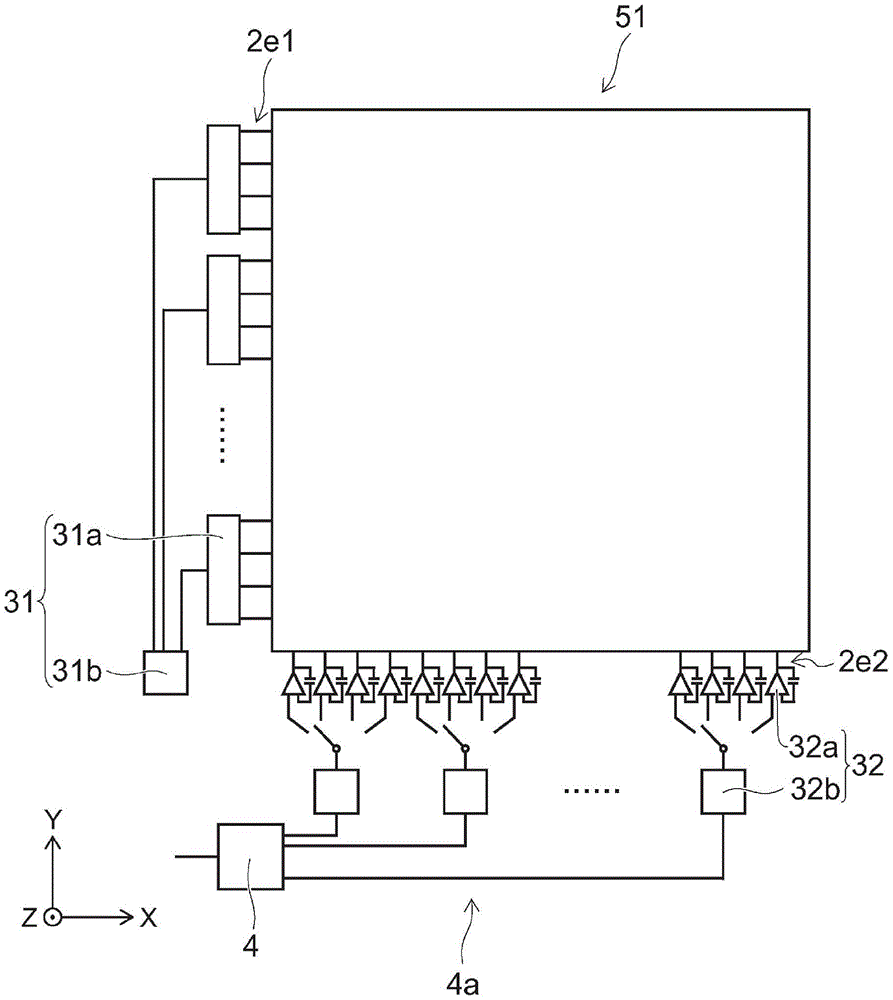

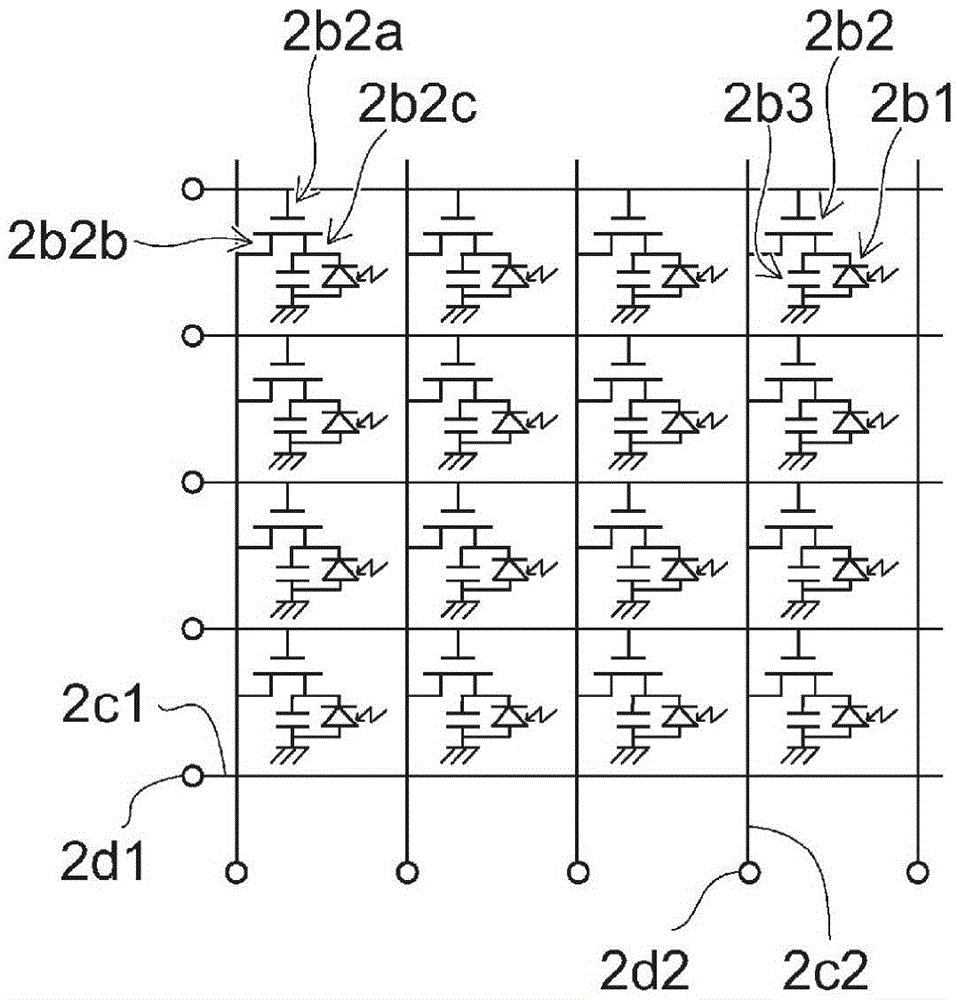

[0029] Hereinafter, various embodiments will be described with reference to the accompanying drawings. In the respective drawings, the same components are denoted by like reference numerals, and their detailed descriptions are omitted as appropriate.

[0030] The wiring substrate according to the embodiment of the present invention may be, for example, a plate-shaped substrate including a wiring pattern thereon. Circuit elements such as semiconductor elements are electrically connected to the wiring patterns.

[0031] An array substrate is an example of such a wiring substrate. The array substrate may be, for example, a plate-like substrate on which wiring patterns are included. Circuit elements such as thin film transistors and photodiodes are electrically connected to the wiring patterns. Such array substrates are used, for example, in flat panel displays and radiation detectors.

[0032] As an example, the present embodiment is described with reference to a radiation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com