Ring Forging Forming Method of Rene41 Alloy

A technology of ring forgings and alloys, applied in metal rolling, metal processing equipment, etc., can solve problems such as easy cracking, product scrapping, unqualified grain size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

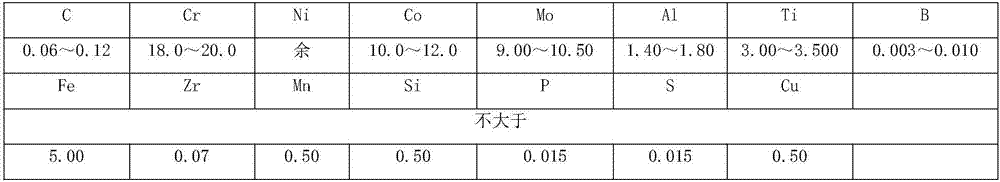

[0026] The chemical composition of Rene41 alloy is as follows:

[0027]

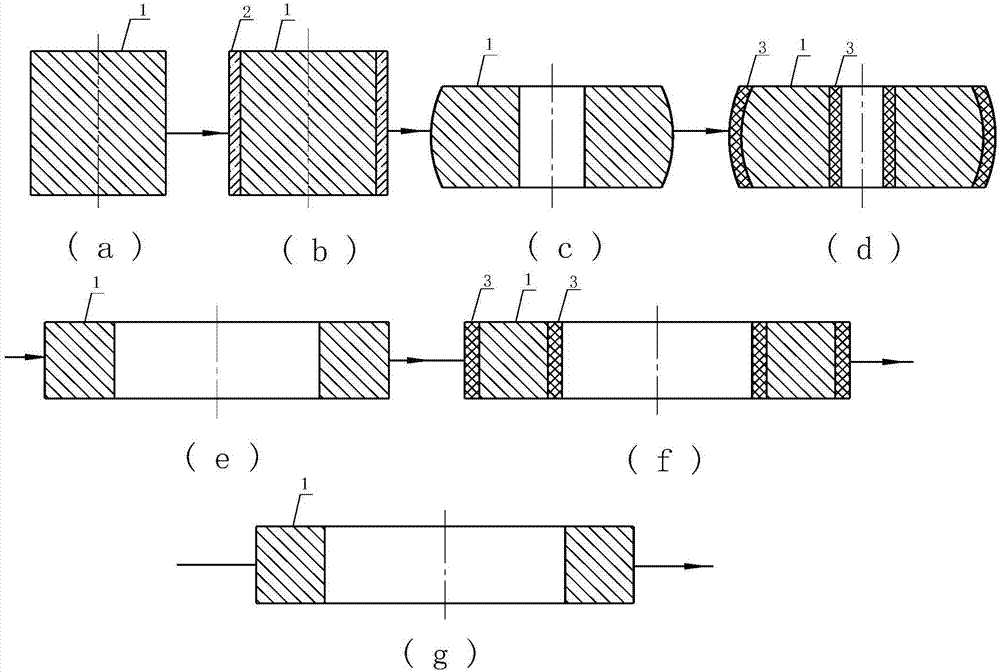

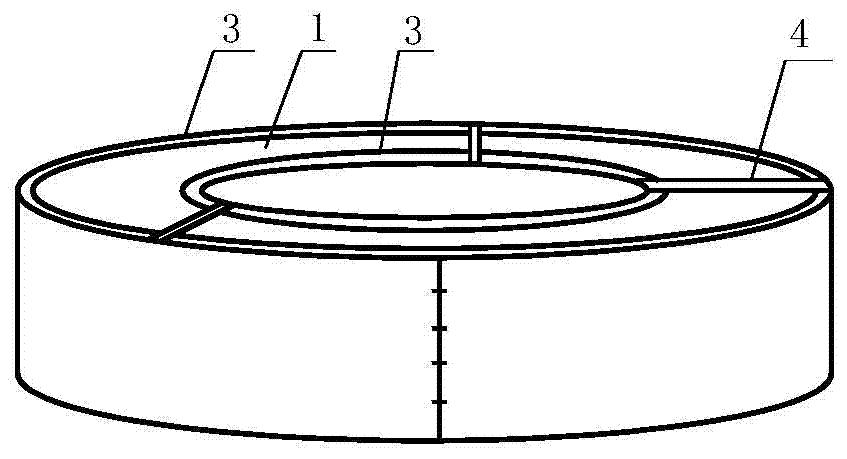

[0028] Such as figure 1 Shown, the annular forging forming method of Rene41 alloy of the present invention is to process the blank of cylindrical Rene41 alloy, and it comprises the following steps:

[0029] (I) if figure 1 Shown in (a) to (c), the first blanket 2 is composed of ceramic fibers with a thickness of 10mm-15mm and high-temperature binder powder with a thickness of 1-2mm evenly sprinkled on it, and the high-temperature binder powder The melting temperature is between 850-900°C. Wrap the above-mentioned first blanket 2 around the cylindrical surface of the Rene41 alloy blank 1, so that the first blanket 2 sprinkled with high-temperature binder powder is closely attached to the cylindrical surface of the above-mentioned blank 1 , and fix the first blanket 2 and the cylindrical surface of the above-mentioned blank 1 together, and then heat them to 1040-1140°C and stop heating, and immediatel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com