Voltage-reduction constant-current type eddy current retarder control system based on pulsing bias amplification

A technology of eddy current retarder and control system, which is applied in electric braking system, electric vehicle, transportation and packaging, etc. It can solve the problems of complex wiring harness, lack of working voltage, and inability to stabilize the control of eddy current retarder. Achieve the effects of reducing wiring harness, improving braking performance and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

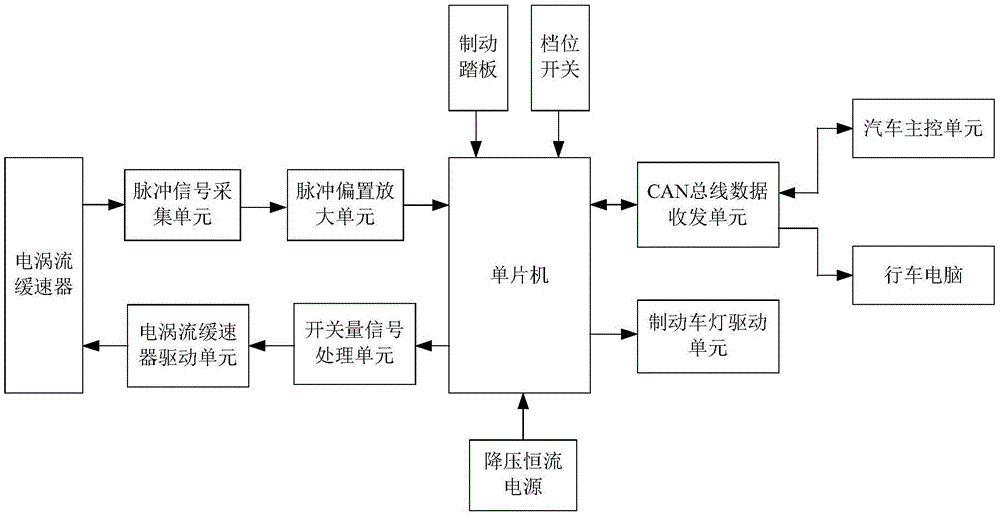

[0021] Such as figure 1 As shown, the step-down constant current eddy current retarder control system based on pulse bias amplification of the present invention is driven by an eddy current retarder, a pulse bias amplification unit, a pulse signal acquisition unit, and an eddy current retarder Unit, switch signal processing unit, single chip microcomputer, brake pedal, gear switch, step-down constant current power supply, CAN bus data transceiver unit, brake light drive unit, car main control unit and trip computer 13 parts.

[0022] Among them, the single-chip microcomputer is used as the control center of the present invention, and it is respectively connected with the step-down constant current power supply, the brake pedal, the gear switch, the pulse bias amplification unit, the switch value signal processing unit, the CAN bus data transceiver unit and the brake light drive. unit is connected. The vehicle main control unit and the driving computer are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com