Method for preparing high-specific-surface-area porous carbon with hemp stems as carbon source

A high specific surface area, porous carbon technology, applied in the field of nano-carbon material preparation, can solve the problems of poor production safety, low specific surface area, harsh reaction conditions, etc., and achieve the effects of low cost, high specific surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

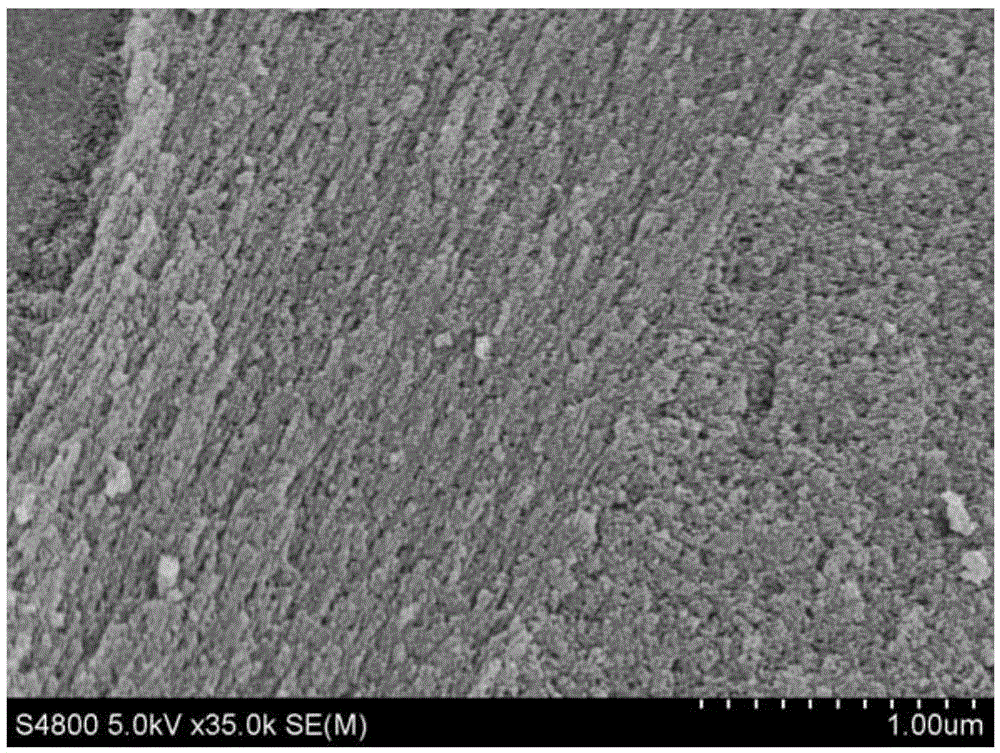

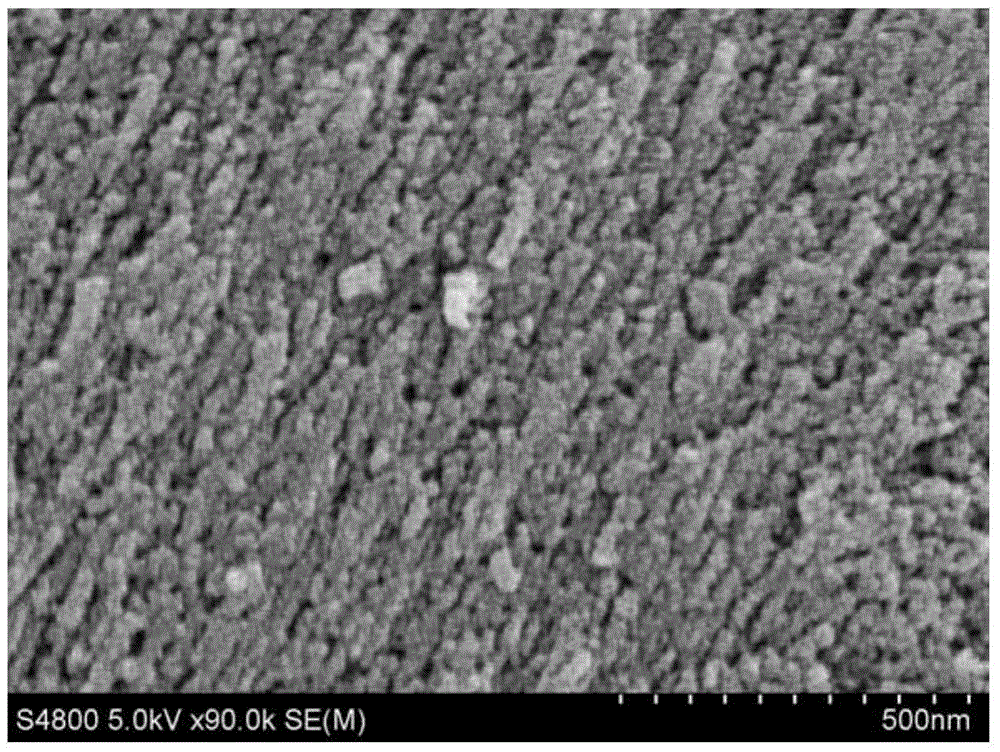

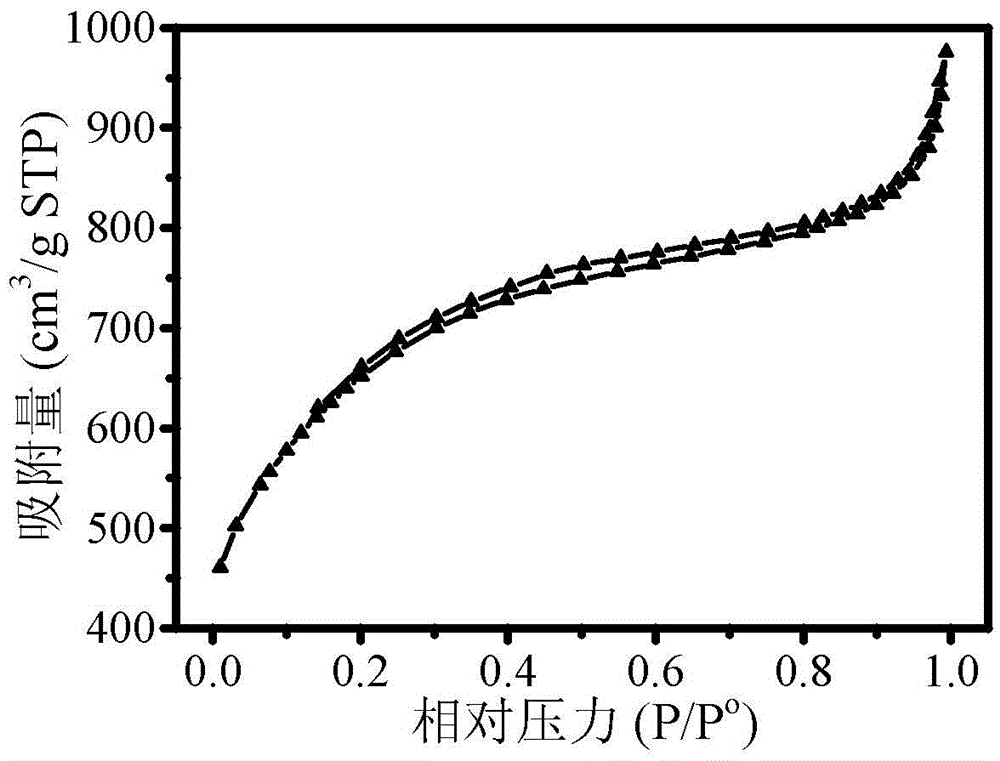

[0030] Embodiment 1: In this embodiment, a method for preparing high specific surface area porous carbon with hemp stalk as a carbon source is carried out according to the following steps:

[0031] Step 1: pulverize the hemp stalk core from which the bast has been removed to a powder, and then dry it at 105° C. for 24 hours to obtain the hemp stalk core powder.

[0032] Step 2, adding 20 g of the hemp stalk core powder obtained in step 1 into 100 ml of the compound catalyst solution, stirring at 80°C until it evaporates to dryness, and drying at 105°C for 24 hours; obtaining a compound precursor;

[0033] Step 3. The composite precursor prepared in step 2 is heated to 900°C at a heating rate of 10°C / min in a nitrogen atmosphere, heat treated at a constant temperature for 2 hours, and then naturally cooled to room temperature;

[0034] Step 4. Then wash with 1mol / L hydrochloric acid, centrifuge and then wash with water until neutral, and dry at 105°C for 12h to obtain porous ca...

specific Embodiment approach 2

[0037] Embodiment 2: In this embodiment, a method for preparing high specific surface area porous carbon with hemp stalk as a carbon source is carried out according to the following steps:

[0038] Step 1: pulverize the hemp stalk core from which the bast has been removed to a powder, and then dry it at 105° C. for 24 hours to obtain the hemp stalk core powder.

[0039] Step 2, adding 30 g of the hemp stalk core powder obtained in step 1 into 100 ml of the compound catalyst solution, stirring at 80°C until it evaporates to dryness, and drying at 105°C for 24 hours; obtaining a compound precursor;

[0040] Step 3. The composite precursor prepared in step 2 is heated to 900°C at a heating rate of 5°C / min in a nitrogen atmosphere, heat treated at a constant temperature for 2 hours, and then naturally cooled to room temperature;

[0041] Step 4. Then wash with 1mol / L hydrochloric acid, centrifuge and then wash with water until neutral, and dry at 105°C for 12h to obtain porous car...

specific Embodiment approach 3

[0044] Specific embodiment three: in this embodiment, a method for preparing high specific surface area porous carbon with hemp stalk as carbon source is carried out according to the following steps:

[0045] Step 1: pulverize the hemp stalk core from which the bast has been removed to a powder, and then dry it at 105° C. for 24 hours to obtain the hemp stalk core powder.

[0046] Step 2, adding 30 g of the hemp stalk core powder obtained in step 1 into 100 ml of the compound catalyst solution, stirring at 80°C until it evaporates to dryness, and drying at 105°C for 24 hours; obtaining a compound precursor;

[0047] Step 3. The composite precursor prepared in step 2 is heated to 800°C at a heating rate of 5°C / min in a nitrogen atmosphere, heat treated at a constant temperature for 2 hours, and then naturally cooled to room temperature;

[0048] Step 4. Then wash with 1mol / L hydrochloric acid, centrifuge and then wash with water until neutral, and dry at 105°C for 12h to obtain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com