Capsule cylindrical microwave flash evaporation device used for heavy metal wastewater treatment

A wastewater treatment and flash evaporation device technology, applied in water/sewage treatment, heating water/sewage treatment, light water/sewage treatment, etc., can solve the problem of slow microwave flash evaporation rate, uneven field distribution, low heat transfer efficiency, etc. problems, to achieve the effect of environment-friendly, energy-saving and high-efficiency, uniform field distribution, pressure resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

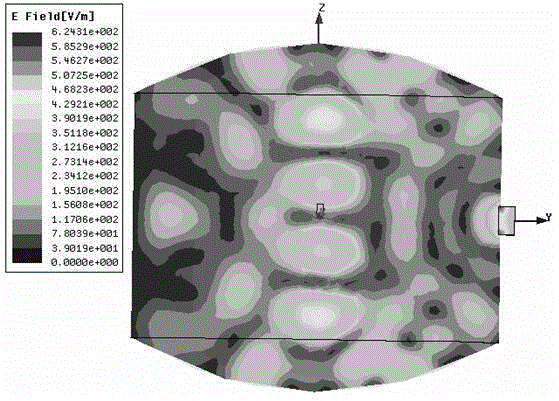

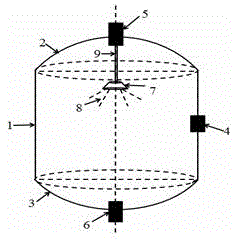

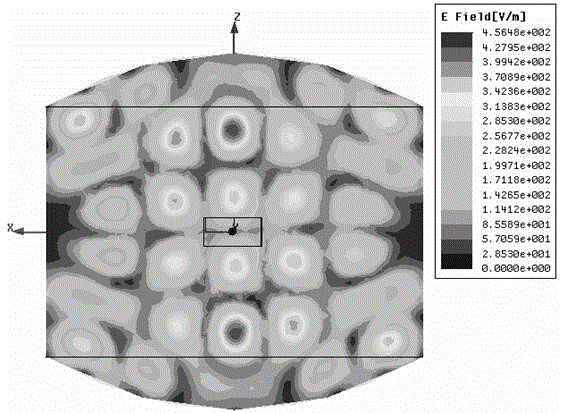

[0030] Embodiment 1: as Figure 1-3As shown, a capsule cylindrical microwave flash device for heavy metal wastewater treatment includes a resonant cavity main body, a microwave feed port 4, a waste liquid inlet 5, a waste liquid outlet 6, a flash nozzle 7, and a waste liquid delivery pipeline 9; The main body of the resonant cavity is composed of an upper metal cavity 2, a cylindrical waveguide 1, and a lower metal cavity 3; the upper metal cavity 2 and the lower metal cavity 3 are located at the upper and lower ends of the cylindrical waveguide 1; The side is closed and fastened with the main body of the resonant cavity. The waste liquid inlet 5 and the waste liquid outlet 6 are arranged on the top and bottom of the main body of the resonant cavity and communicate with the inner cavity. The flash nozzle 7 is set in the main body of the resonant cavity. 9 Connect the waste liquid inlet 5 and the flash nozzle 7.

[0031] The main body of the resonant cavity is capsule cylindri...

Embodiment 2

[0034] Embodiment 2: as Figure 1-3 As shown, a capsule cylindrical microwave flash device for heavy metal wastewater treatment includes a resonant cavity main body, a microwave feed port 4, a waste liquid inlet 5, a waste liquid outlet 6, a flash nozzle 7, and a waste liquid delivery pipeline 9; The main body of the resonant cavity is composed of an upper metal cavity 2, a cylindrical waveguide 1, and a lower metal cavity 3; the upper metal cavity 2 and the lower metal cavity 3 are located at the upper and lower ends of the cylindrical waveguide 1; The side is closed and fastened with the main body of the resonant cavity. The waste liquid inlet 5 and the waste liquid outlet 6 are arranged on the top and bottom of the main body of the resonant cavity and communicate with the inner cavity. The flash nozzle 7 is set in the main body of the resonant cavity. 9 Connect the waste liquid inlet 5 and the flash nozzle 7.

[0035] The main body of the resonant cavity is capsule cylindr...

Embodiment 3

[0041] Embodiment 3: as Figure 1-3 As shown, a capsule cylindrical microwave flash device for heavy metal wastewater treatment includes a resonant cavity main body, a microwave feed port 4, a waste liquid inlet 5, a waste liquid outlet 6, a flash nozzle 7, and a waste liquid delivery pipeline 9; The main body of the resonant cavity is composed of an upper metal cavity 2, a cylindrical waveguide 1, and a lower metal cavity 3; the upper metal cavity 2 and the lower metal cavity 3 are located at the upper and lower ends of the cylindrical waveguide 1; The side is closed and fastened with the main body of the resonant cavity. The waste liquid inlet 5 and the waste liquid outlet 6 are arranged on the top and bottom of the main body of the resonant cavity and communicate with the inner cavity. The flash nozzle 7 is set in the main body of the resonant cavity. 9 Connect the waste liquid inlet 5 and the flash nozzle 7.

[0042] The main body of the resonant cavity is capsule cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com