Modified gypsum base screed and preparation and application thereof

A mortar and gypsum technology, applied in the field of modified gypsum-based floor mortar and its preparation and application, can solve the problems of large shrinkage, poor bonding performance, increased maintenance costs in the later period, etc., to improve strength, reduce material usage, resist The effect of hollow drum cracking performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of building gypsum in Example 1-4 is: phosphogypsum is pre-mixed with desulfurized gypsum at a mass ratio of 1:1 after being properly pretreated to neutrality (pH≈7), and the tail steam generated by the power plant generates gypsum at 75 After drying at ℃, calcining at 150℃ for 2 hours; then grinding to 200 mesh; aging for 7 days after cooling.

[0073] The production method and test method of the test piece in the embodiment are carried out in accordance with the relevant regulations of GBT17671-1999 cement mortar strength test method (ISO method), wherein the test piece is mixed with a modified gypsum-based floor mortar and an appropriate amount of water to form a certain fluidity. The plastic sand with high density can be molded, and the shrinkage rate is carried out in accordance with the relevant regulations of the building materials industry standard JC / T985-2005 cement-based self-leveling mortar for the ground.

Embodiment 1

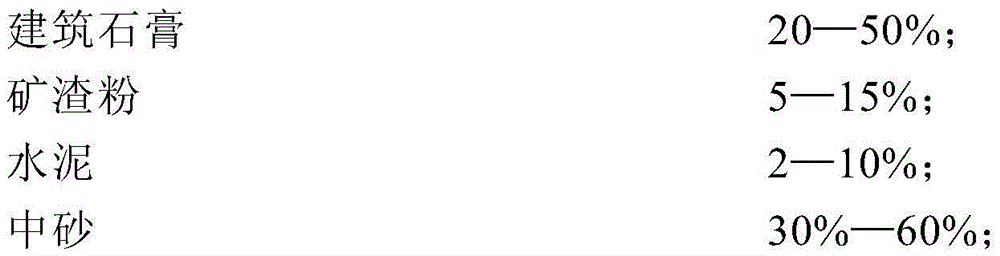

[0075] The main ingredients of the modified gypsum-based floor mortar are: 30% building gypsum, 5% slag powder, 5% cement, and 60% medium sand;

[0076] The building admixture and its percentage per thousand to the mass of the main material are: retarder 1‰, water reducing agent 0.2‰;

[0077] The ratio of water to material is 0.29;

[0078] The performance is as follows:

[0079]

[0080]

Embodiment 2

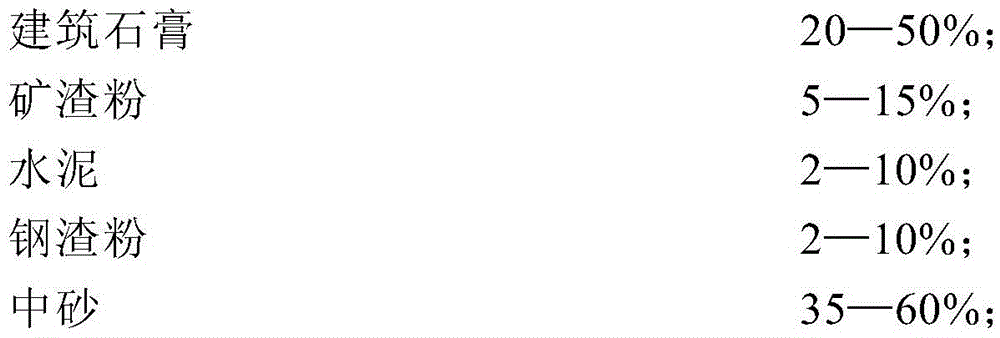

[0082] The main ingredients of the modified gypsum base mortar are: 33% building gypsum, 5% slag powder, 5% cement, 2% steel slag powder, medium sand, 55%;

[0083] The building admixture and its percentage per thousand to the mass of the main material are: retarder 0.9‰;

[0084] The ratio of water to material is 0.31;

[0085] The performance is as follows:

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com