BaFe12O19 composite powder and preparation method thereof

A technology of bafe12o19 and xbafe12o19, which is applied in the field of BaFe12O19-based composite powder and its preparation, can solve problems such as poor impedance matching characteristics, ferrite cannot meet magnetic properties, and poor wave-absorbing performance, and achieve improved impedance matching characteristics and excellent wave-absorbing properties Performance, the effect of optimizing the absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

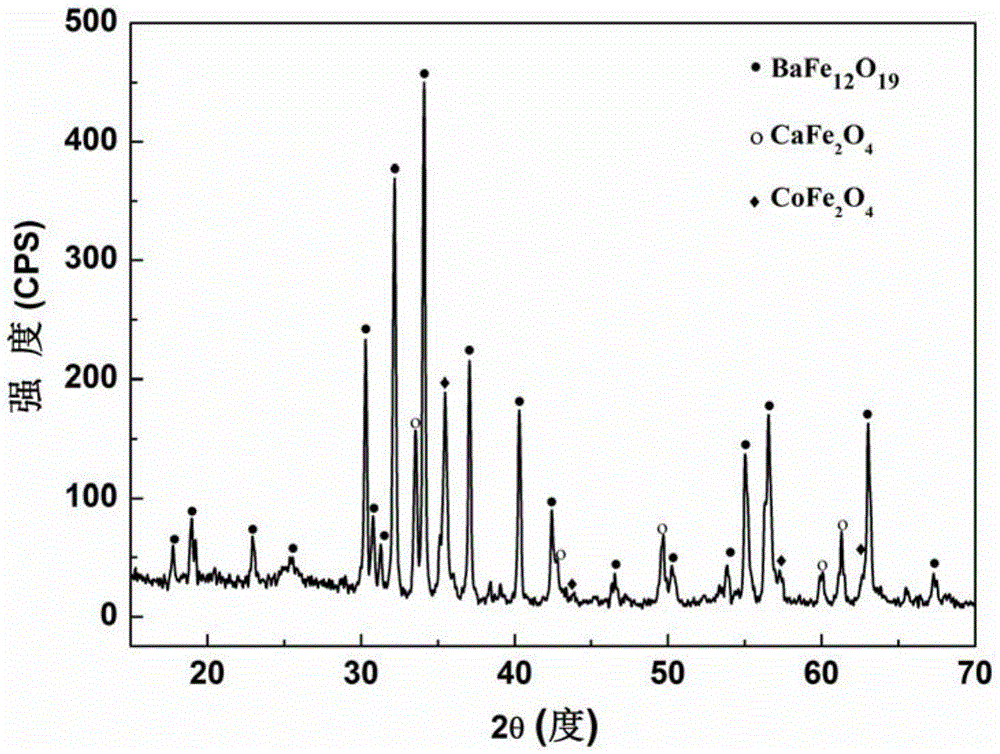

Embodiment 1

[0033] 1) by BaFe 12 o 19 , CaFe 2 o 4 The molar ratio is 1:2, the analytically pure Ba(NO 3 ), Ca(NO 3 ) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O and C 6 h 8 o 7 ·H 2 O (citric acid) was dissolved in deionized water, then ammonia water was added dropwise to adjust the pH value to 6.8, stirred evenly at 85°C and then dried to obtain xerogel; then the obtained xerogel was ground and calcined at 950°C And keep warm for 3.5 hours to get BaFe 12 o 19 / CaFe 2 o 4 Composite powder.

[0034] 2) BaFe 12 o 19 / CaFe 2 o 4 The composite powder and commercial nano-cobalt ferrite powder are mixed uniformly according to the mass ratio x: (1-x), and then heat treated at 500 ° C for 4 hours to obtain xBaFe 12 o 19 / CaFe 2 o 4 / (1-x)CoFe 2 o 4 Composite powder; wherein, x is 0.9;

[0035] 3) Add 1gxBaFe 12 o 19 / CaFe 2 o 4 / (1-x)CoFe 2 o 4 The composite powder was dissolved in 100mL of 1mol / L hydrochloric acid solution, and after stirring for 30 minutes, aniline was added...

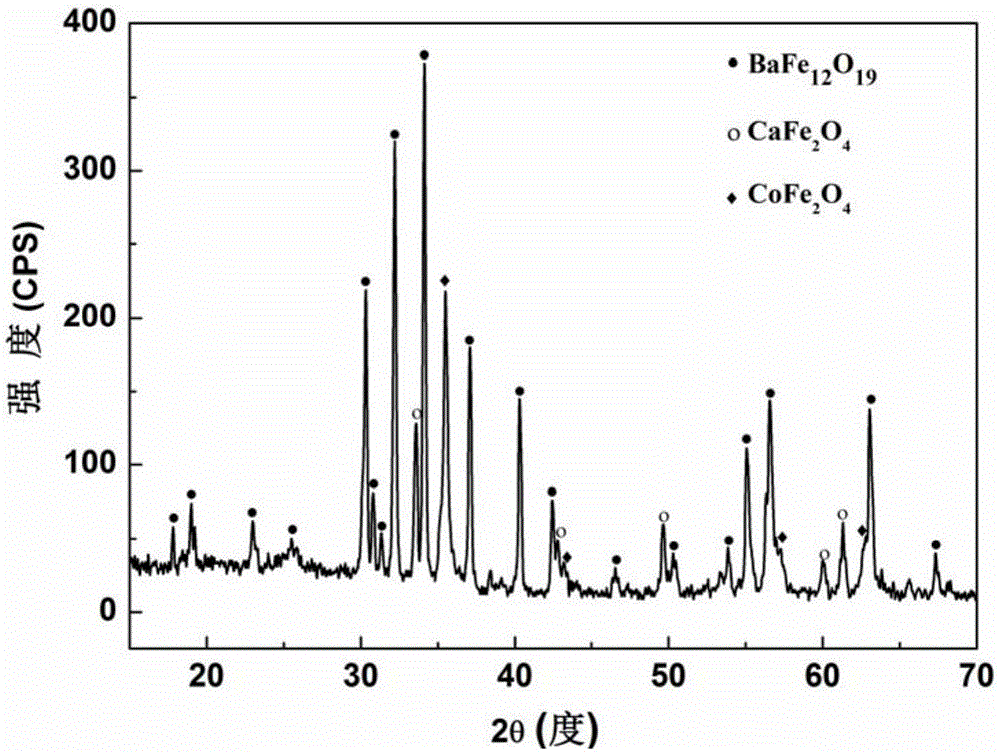

Embodiment 2

[0040] 1) by BaFe 12 o 19 , CaFe 2 o 4 The molar ratio is 1:2, the analytically pure Ba(NO 3 ), Ca(NO 3 ) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O and C 6 h 8 o 7 ·H 2 O (citric acid) was dissolved in deionized water, then ammonia water was added dropwise to adjust the pH value to 7, stirred evenly at 80°C and then dried to obtain xerogel; then the obtained xerogel was ground and calcined at 1000°C And keep warm for 3 hours to get BaFe 12 o 19 / CaFe 2 o 4 Composite powder.

[0041] 2) BaFe 12 o 19 / CaFe 2 o 4 The composite powder and commercial nano-cobalt ferrite powder are mixed uniformly according to the mass ratio x: (1-x), and then heat-treated at 480°C for 5 hours to obtain xBaFe 12 o 19 / CaFe 2 o 4 / (1-x)CoFe 2 o 4 Composite powder; wherein, x is 0.8;

[0042] 3) Add 1gxBaFe 12 o 19 / CaFe 2 o 4 / (1-x)CoFe 2 o 4 The composite powder was dissolved in 100mL of 1mol / L hydrochloric acid solution, and after stirring for 40 minutes, aniline was added; the...

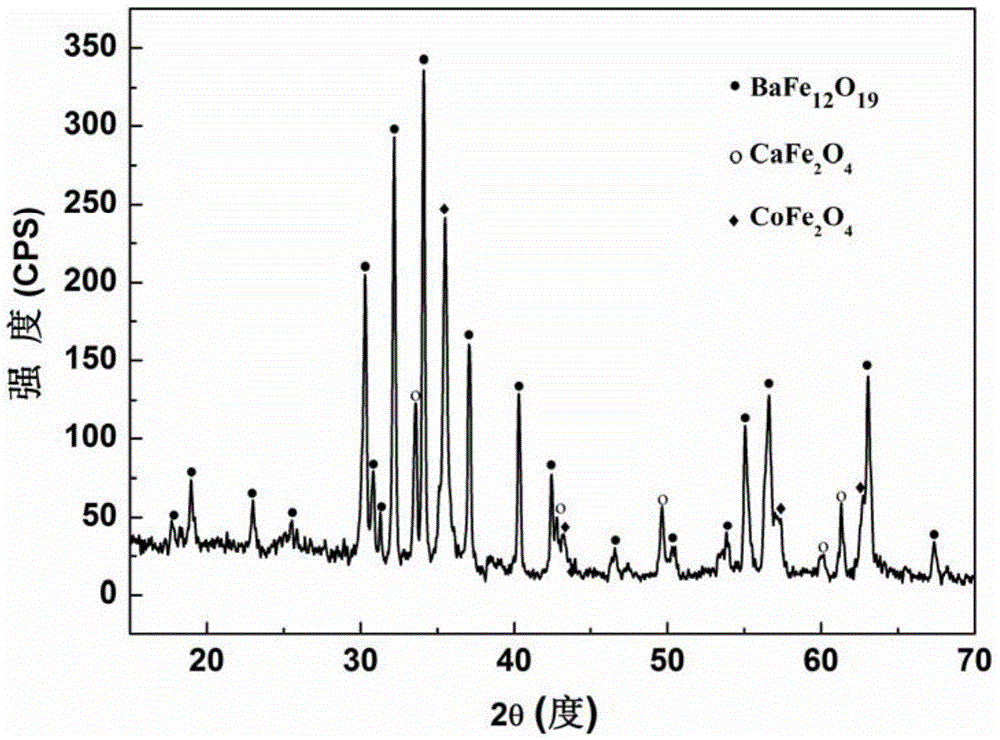

Embodiment 3

[0047] 1) by BaFe 12 o 19 , CaFe 2 o 4 The molar ratio is 1:2, the analytically pure Ba(NO 3 ), Ca(NO 3 ) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O and C 6 h 8 o 7 ·H 2 O (citric acid) was dissolved in deionized water, then ammonia water was added dropwise to adjust the pH value to 7.2, stirred evenly at 75°C and then dried to obtain xerogel; then the obtained xerogel was ground and calcined at 900°C And keep warm for 4 hours to get BaFe 12 o 19 / CaFe 2 o 4 Composite powder.

[0048] 2) BaFe 12 o 19 / CaFe 2 o 4 The composite powder and commercial nano-cobalt ferrite powder are mixed evenly according to the mass ratio x: (1-x), and then heat treated at 520°C for 4 hours to obtain xBaFe 12 o 19 / CaFe 2 o 4 / (1-x)CoFe 2 o 4 Composite powder; wherein, x is 0.7;

[0049] 3) Add 1gxBaFe 12 o 19 / CaFe 2 o 4 / (1-x)CoFe 2 o 4 The composite powder was dissolved in 100mL of 1mol / L hydrochloric acid solution, and after stirring for 50 minutes, aniline was added; then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com