Car wire propenyl plastic compatilizer and preparation method thereof

A propylene-based, compatibilizer technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems affecting the aging performance and poor compatibility of polypropylene cable materials, and achieve excellent compatibility. Capacitance, improve scratch resistance, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A kind of propylene-based plastic compatibilizer for automobile wire and its preparation method

[0030] Preparation method: After the materials in the raw material formula are prepared according to their respective weight parts, they are first sent to a high-speed mixer and kneaded for 20 to 60 minutes to obtain a mixture, and then the mixture is sent to a twin-screw extruder for extrusion For granulation, the extrusion temperature is 170~220°C, and the screw speed is 250~360rpm.

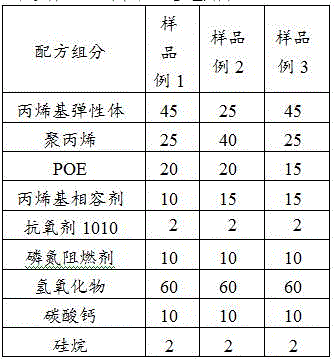

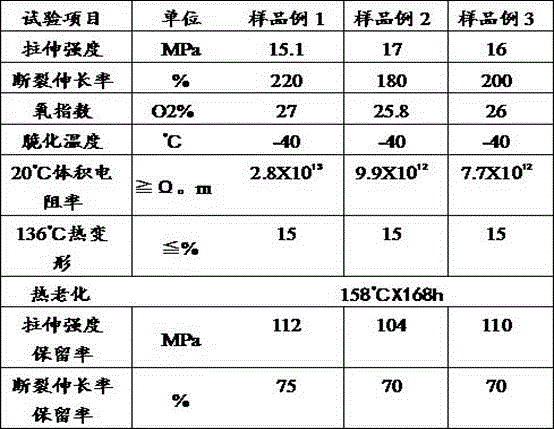

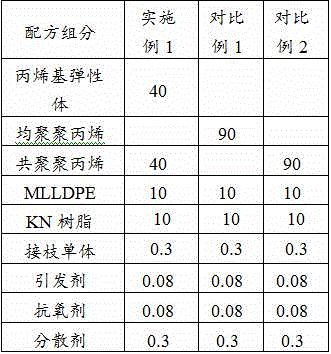

[0031] Then, Comparative Example 1 and Comparative Example 2 were prepared using similar raw material formulations and preparation methods. The difference was that Comparative Example 1 and Comparative Example 2 did not add propylene-based elastomers, and Comparative Example 1 added homopolypropylene. Examples and comparative examples are prepared by the preparation method of the present invention. See Table 1 below for the proportions of parts by weight of Example 1, Comparative...

Embodiment 2~4

[0046] Embodiment 2~4: A kind of propylene-based plastic compatibilizer for automobile wire and its preparation method

[0047] Preparation method: After the materials in the raw material formula are prepared according to their respective weight parts, they are first sent to a high-speed mixer and kneaded for 20 to 60 minutes to obtain a mixture, and then the mixture is sent to a twin-screw extruder for extrusion For granulation, the extrusion temperature is 170~220°C, and the screw speed is 250~360rpm.

[0048] The raw material formula of table 5 embodiment 2~4 (unit: weight part)

[0049]

[0050] Further notes on Table 5:

[0051] 1. The melt index of the propylene-based elastomers in Examples 2 to 4 is 1 to 10 g / 10 minutes, and the weight percentage of vinyl contained in the propylene-based elastomers is 10 to 20%, specifically the grade VM3020 The product is produced by ExxonMobil Corporation of the United States and imported;

[0052] 2, the copolymerized polypropyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com