High-strength wood-plastic composite material, preparation method therefor, sectional material and application thereof

A wood-plastic composite material and high-strength technology, applied in the field of composite materials, can solve the problems of easy deformation, poor hardness, and easy pits, etc., and achieve long service life and physical application performance indicators, high elastic flexural modulus, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

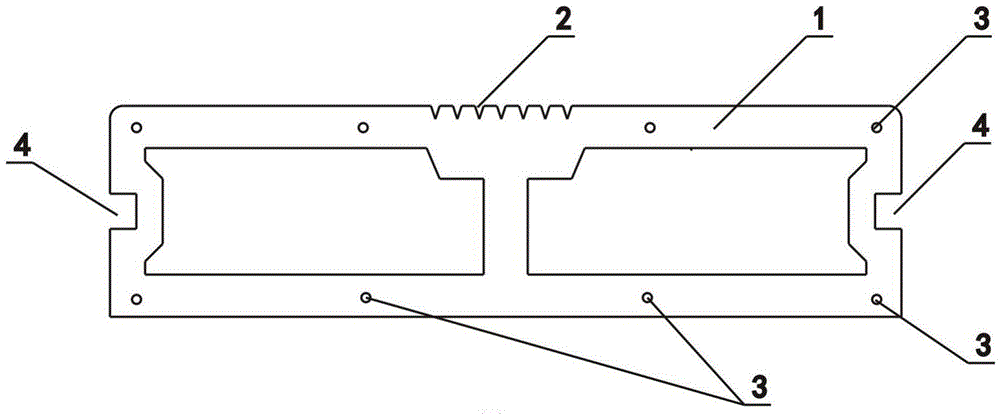

Image

Examples

Embodiment 1

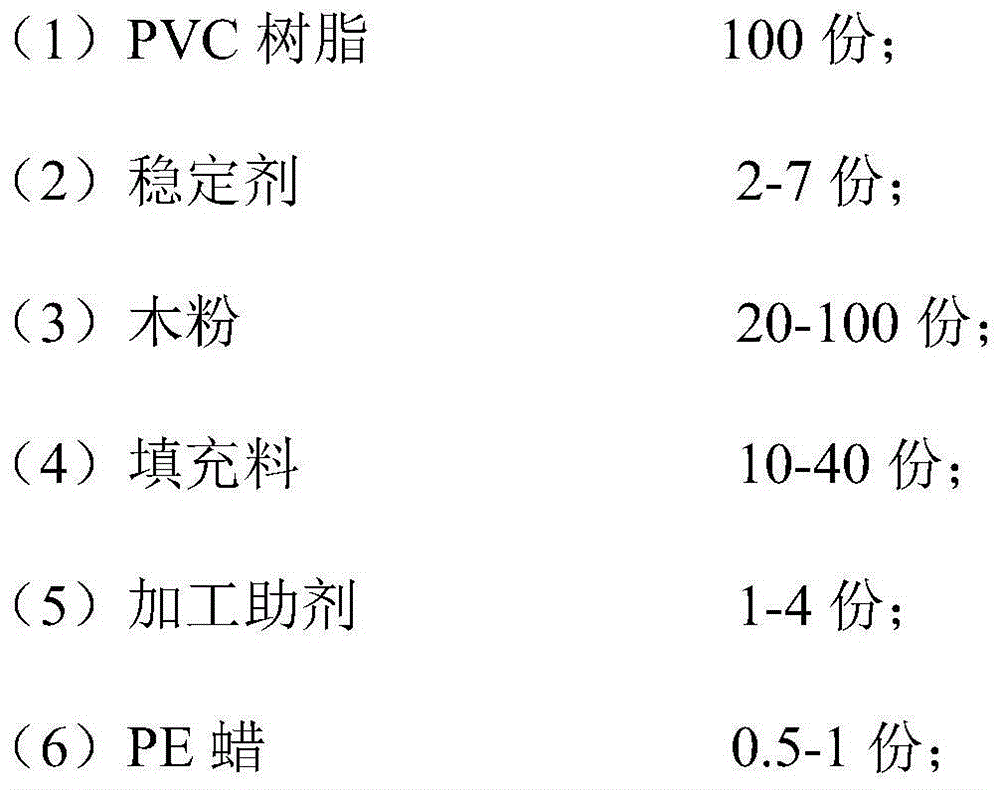

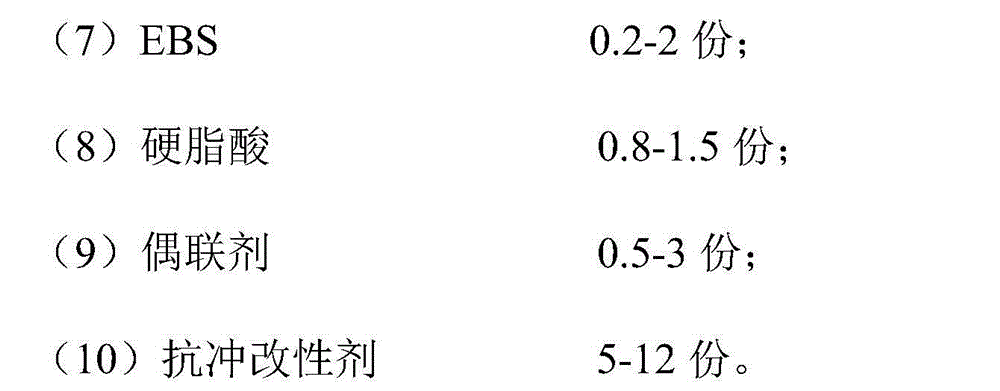

[0032] As an embodiment of the high-strength wood-plastic composite material of the present invention, it includes the following components:

[0033]

[0034] In the present embodiment, the particle size of the wood flour is 50 mesh; the PVC resin is type 5 resin; the stabilizer is an organotin stabilizer; the filler is calcium carbonate; It is LX-901; the stearic acid is 1801 stearic acid; the coupling agent is a silane coupling agent; the impact modifier is CPE; the melting point temperature of the PE wax is 105 ° C; The melting point temperature of EBS is 142°C.

[0035] A method for preparing a high-strength wood-plastic composite material, comprising the following steps:

[0036] (1) Accurately weigh each raw material according to the formula ratio;

[0037] (2) Put the weighed wood powder into the hot mixing pot first, control the moisture content of the wood powder below 2%, and then add PVC resin, stabilizer, filler, processing aid, PE wax, EBS, stearic acid , co...

Embodiment 2

[0047] As an embodiment of the high-strength wood-plastic composite material of the present invention, the difference from Embodiment 1 is that in this embodiment, the high-strength wood-plastic composite material includes the following components:

[0048]

[0049] In the present embodiment, the particle size of the wood powder is 40 mesh; the PVC resin is a type 7 resin; the stabilizer is a calcium-zinc stabilizer; the filler is kaolin; ACR201; the coupling agent is titanium grease coupling agent; the impact modifier is ACR.

[0050] A method for preparing a high-strength wood-plastic composite material, comprising the following steps:

[0051] (1) Accurately weigh each raw material according to the formula ratio;

[0052] (2) Put the weighed wood powder into the hot mixing pot first, control the moisture content of the wood powder below 2%, and then add PVC resin, stabilizer, filler, processing aid, PE wax, EBS, stearic acid , coupling agent, and impact modifier, stirr...

Embodiment 3

[0059] As an embodiment of the high-strength wood-plastic composite material of the present invention, the difference from Embodiment 1 is that in this embodiment, the high-strength wood-plastic composite material includes the following components:

[0060]

[0061]

[0062] In the present embodiment, the particle size of the wood flour is 60 mesh; the stabilizer is a lead salt composite stabilizer; the filler is talcum powder; the processing aid is ACR401; the coupling agent It is an aluminate coupling agent; the impact modifier is MBS.

[0063] A method for preparing a high-strength wood-plastic composite material, comprising the following steps:

[0064] (1) Accurately weigh each raw material according to the formula ratio;

[0065] (2) Put the weighed wood powder into the hot mixing pot first, control the moisture content of the wood powder below 2%, and then add PVC resin, stabilizer, filler, processing aid, PE wax, EBS, stearic acid , coupling agent, and impact m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com