Ultra-low stress addition type silicone rubber composition

A technology of silicone rubber and addition molding, which is applied in the field of ultra-low stress addition molding silicone rubber compositions, and can solve the problems of low elastic modulus, low stress, and difficulty in sealing the composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

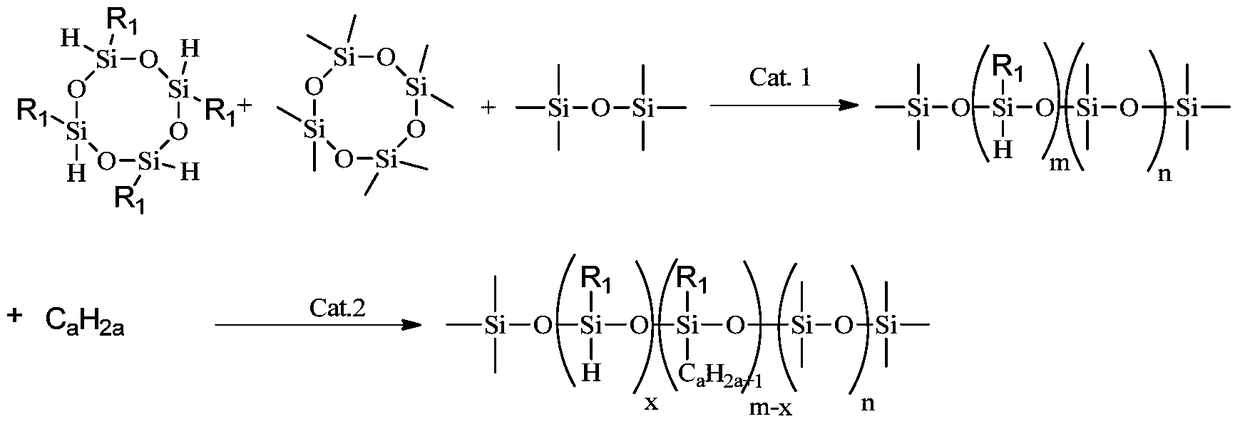

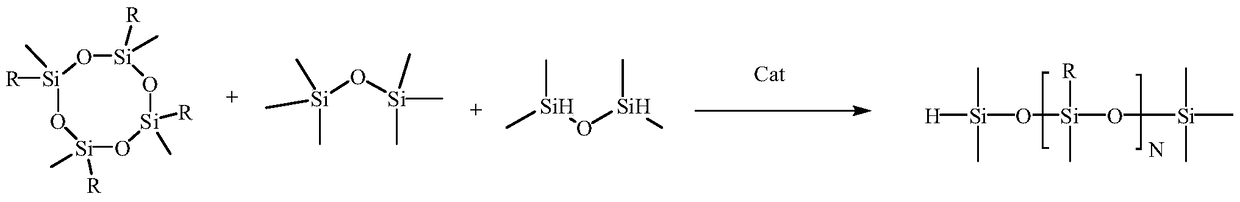

Method used

Image

Examples

Embodiment 1

[0065] The structural formula is Me 3 SiO (MeViSiO) 20 (MePhSiO) 50 (Me 2 SiO) 30 SiMe 3 100 parts by mass of vinyl-containing organopolydisiloxane, the structural formula is Me 3 SiO(MeHSiO) 10 (MePhSiO) 10 (Me 2 SiO) 5 SiMe 3 15 parts by mass of a crosslinking agent, 0.5 parts by mass of a catalyst with a platinum content of 500 ppm, and a molecular structure of Me 2 HSiO(MePhSiO) 50 SiMe 3 30 parts by mass of the low-stress additive, mixed uniformly and cured to obtain an ultra-low stress addition type silicone rubber. The test results are shown in Table 1.

Embodiment 2

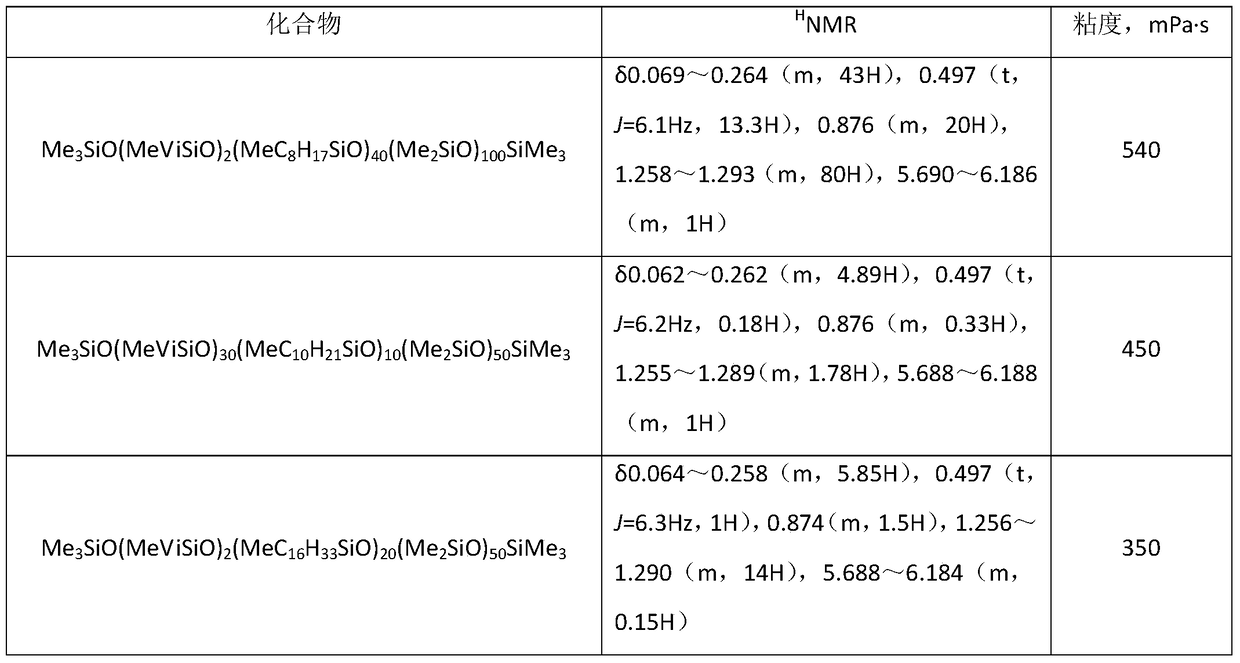

[0067] The structural formula is Me 3 SiO (MeViSiO) 2 (MeC 8 h 17 SiO) 40 (Me 2 SiO) 100 SiMe 3 100 parts by mass of vinyl-containing organopolydisiloxane, the structural formula is Me 3 SiO(MeHSiO) 2 (MeC 8 h 17 SiO) 8 SiMe 3 12 parts by mass of crosslinking agent, 0.1 part by mass of catalyst with platinum content of 3000ppm, molecular structure of Me 2 HSiO(MePhSiO) 40 SiMe 3 10 parts by mass of the low-stress additive and 100 parts by mass of aluminum hydroxide were mixed uniformly and cured to obtain an ultra-low stress addition type silicone rubber. The test results are shown in Table 1.

Embodiment 3

[0069] The structural formula is Me 3 SiO (MeViSiO) 30 (MeC 10 h 21 SiO) 10 (Me 2 SiO) 50 SiMe 3 100 parts by mass of vinyl-containing organopolydisiloxane, the structural formula is Me 3 SiO(MeHSiO) 2 (MeC 10 h 21 SiO) 6 (Me 2 SiO) 10 SiMe 3 5 parts by mass of a crosslinking agent, 0.3 parts by mass of a catalyst with a platinum content of 600 ppm, and a structural formula of Me 2 HSiO(MeC 10 h 21 SiO) 30 SiMe 3 20 parts by mass of the low-stress additive, 100 parts by mass of aluminum hydroxide, and 100 parts by mass of silicon micropowder, mixed uniformly and cured to obtain an ultra-low stress addition type silicone rubber. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com