Fiber reinforced thermoplasticity plastic

A technology for strengthening thermoplastics and thermoplastics, applied in the field of material science, can solve the problems of insufficient performance of bamboo raw materials, damage to the structure of bamboo fibers, etc., and achieve the effects of good strength, low production cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

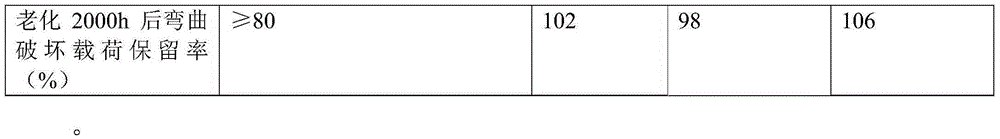

Embodiment 1

[0034] A kind of bamboo fiber reinforced thermoplastics is made by mixing the raw materials in following parts by weight: 30 parts of bamboo fiber, 30 parts of thermoplastics (polyvinyl chloride, commercially available), coupling agent (titanate coupling agent, commercially available) ) 0.25 parts, crosslinking agent (dicumyl peroxide) 0.3 parts, lubricant 0.5 parts.

[0035] Preparation method, the steps are as follows:

[0036] (1) first drop into bamboo fiber and coupling agent in the high-speed mixing mixer, stir 5min with the stirring velocity of 500rpm, then drop into thermoplastics, cross-linking agent and lubricant, stir 5min with the stirring velocity of 1200rpm, obtain stirring evenly mixed materials;

[0037] (2) feeding the mixed material obtained in step (1) into a twin-screw extruder for extrusion, wherein the temperature in the melting zone is 155° C., and the temperature in the extrusion zone is 175° C. to obtain an extruded product;

[0038] (3) cooling the ...

Embodiment 2

[0047] A kind of bamboo fiber reinforced thermoplastics is made by mixing the raw materials in following parts by weight: 60 parts of bamboo fibers, 80 parts of thermoplastics (polypropylene, commercially available), coupling agent (silane coupling agent KH550, commercially available) 0.6 part, 0.8 part of crosslinking agent (benzoyl peroxide, commercially available), and 1.5 part of lubricant.

[0048] Preparation method, the steps are as follows:

[0049] (1) first drop into bamboo fiber and coupling agent in the high-speed mixing mixer, stir 3min with the stirring speed of 700rpm, then drop into thermoplastics, cross-linking agent and lubricant, stir 2min with the stirring speed of 1500rpm, obtain stirring evenly mixed materials;

[0050] (2) feeding the mixed material obtained in step (1) into a twin-screw extruder for extrusion, wherein the temperature in the melting zone is 170° C., and the temperature in the extrusion zone is 185° C. to obtain an extruded product;

[00...

Embodiment 3

[0059] A kind of bamboo fiber reinforced thermoplastics is made by mixing the following raw materials in parts by weight: 40 parts of bamboo fibers, 60 parts of thermoplastics (20 parts of polyethylene+40 parts of polyvinyl chloride), coupling agent (titanate coupling agent) 0.4 parts, cross-linking agent (0.3 parts of dicumyl peroxide + 0.3 parts of benzoyl peroxide) 0.6 parts, lubricant 1 part.

[0060] Preparation method, the steps are as follows:

[0061] (1) first drop into bamboo fiber and coupling agent in the high-speed mixing mixer, stir 4min with the stirring speed of 600rpm, then drop into thermoplastics, cross-linking agent and lubricant, stir 3min with the stirring speed of 1300rpm, obtain stirring evenly mixed materials;

[0062] (2) feeding the mixed material obtained in step (1) into a twin-screw extruder for extrusion, wherein the temperature in the melting zone is 160° C., and the temperature in the extrusion zone is 180° C. to obtain an extruded product;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com