Oil-based drilling fluid plugging agent

A technology of oil-based drilling fluid and loss-stopping agent, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of economic loss, material waste, and high cost of oil-based drilling fluid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

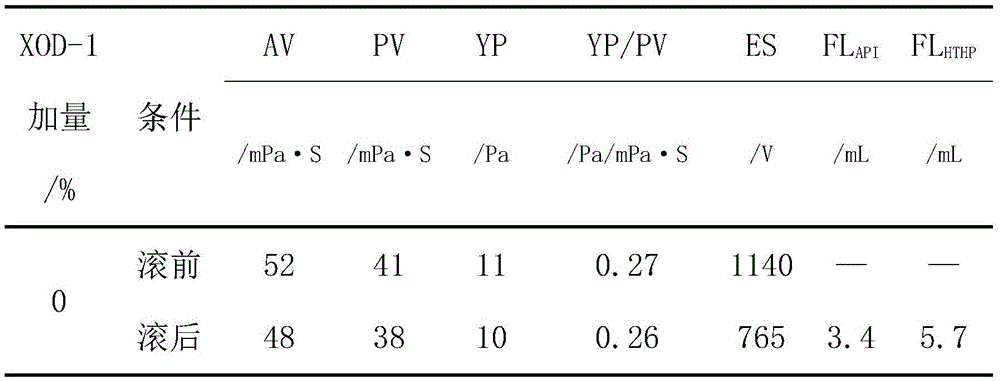

Embodiment 1

[0039] (1), choose 55 parts of quartz sand powder with a particle size not greater than 0.9mm, 20 parts of a mixture of cottonseed hull powder and sawdust powder with a particle size not greater than 0.3mm, 10 parts of rubber powder with a particle size not greater than 0.3mm, four 10 parts of cycloaromatic hydrocarbons, 4.5 parts of acrylic acid-acrylamide-acrylonitrile copolymer, 0.5 parts of Tween 80, stirred and mixed evenly according to the weight ratio;

[0040] (2) Put the mixture obtained in step (1) into a kneader, heat it to 120°C, react for 4 to 12 hours, cool it naturally, and crush it to a particle size or powder with a particle size of less than 0.9mm, that is, to obtain The oil-based drilling fluid plugging agent is code-named XOD-1.

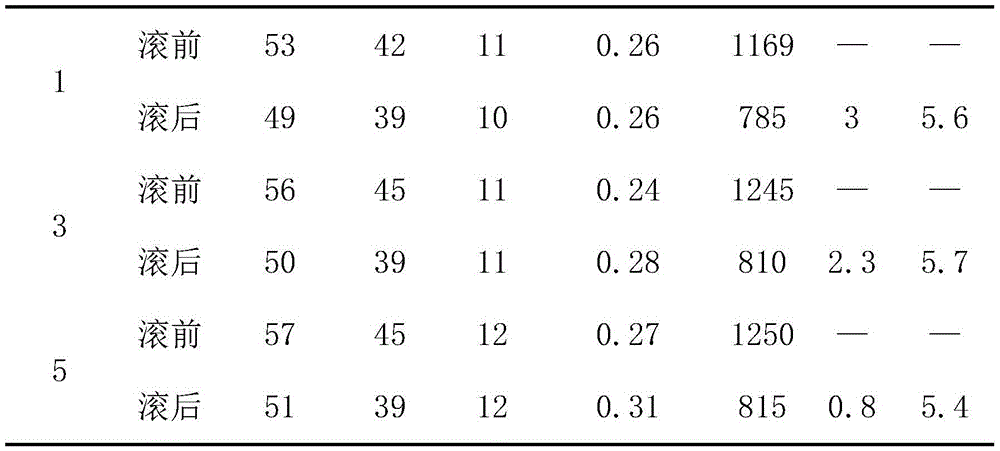

Embodiment 2

[0042] (1), choose 45 parts of quartz sand powder with a particle size not greater than 0.9mm, 18 parts of a mixture of cottonseed hull powder and sawdust powder with a particle size not greater than 0.3mm, and 20 parts of rubber powder with a particle size not greater than 0.3mm. 20 parts of cycloaromatic hydrocarbons, 8 parts of acrylic acid-acrylamide-acrylonitrile copolymer, 1.5 parts of Tween 80, stirred and mixed evenly according to the weight ratio;

[0043] (2) Put the mixture obtained in step (1) in a kneader at 130°C, stir and react for 4 to 12 hours, then cool naturally, and pulverize into granular or powder with a particle size of less than 0.9mm, that is, to obtain oil-based The drilling fluid plugging agent is code-named XOD-2.

Embodiment 3

[0045] (1) Select 50 parts of calcite mineral powder with a particle size not greater than 0.9mm, 25 parts of a mixture of cottonseed husk powder and rice husk powder with a particle size not greater than 0.3mm, 15 parts of rubber powder with a particle size not greater than 0.3mm, Sihuan 15 parts of aromatic hydrocarbons, 5.5 parts of acrylic acid-acrylamide-acrylonitrile copolymer, 2 parts of OP-15, stirred and mixed evenly according to the weight ratio;

[0046] (2) Put the mixture obtained in step (1) into a kneader, heat it to 130°C, stir and react for 4 to 12 hours, then cool it naturally, and crush it into granular or powder with a particle size of less than 0.9mm to obtain The oil-based drilling fluid plugging agent is code-named XOD-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com