Rolling needle roller block type automobile differential characterized by arbitrary tooth difference internal cam shock waves

A technology for automotive differentials and differentials, which is applied to differential transmissions, belts/chains/gears, mechanical equipment, etc., and can solve the difficulties in processing straight bevel gears, large axial and radial dimensions, volume and Weight increase and other issues, to achieve the effect of light weight, small axial and radial dimensions, and high coincidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

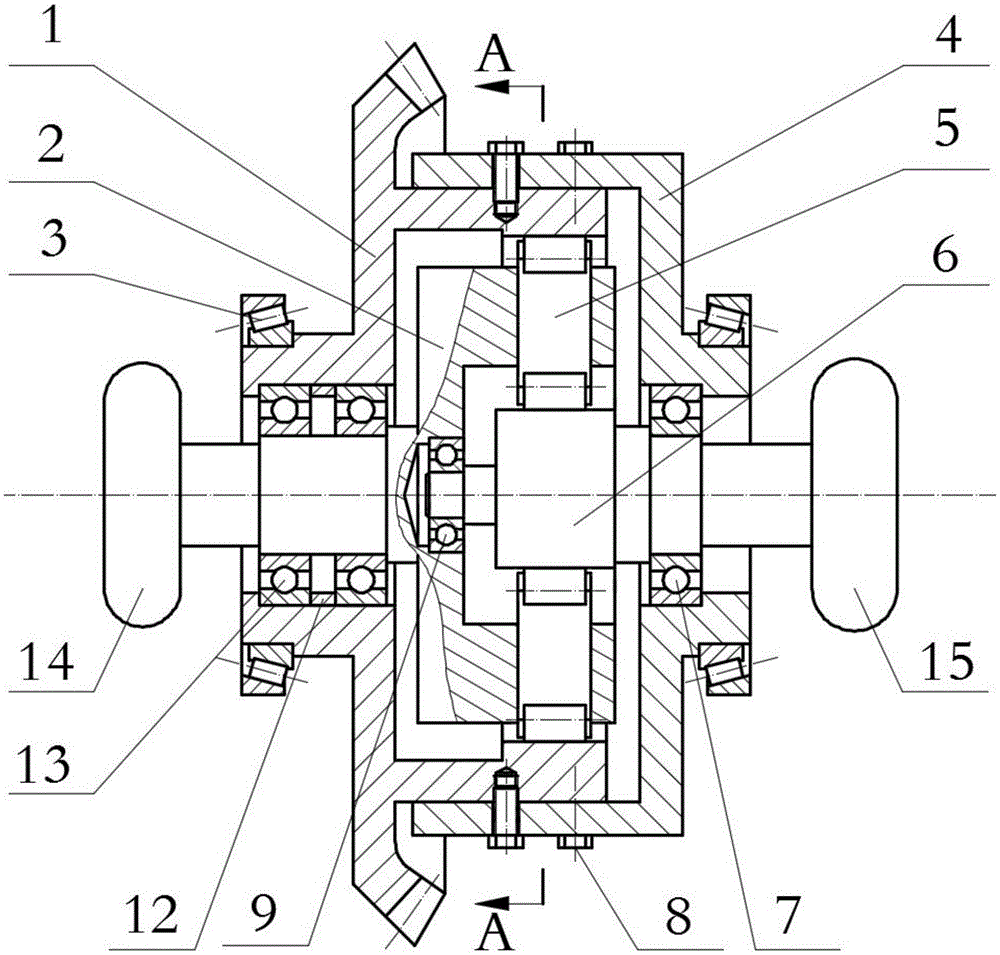

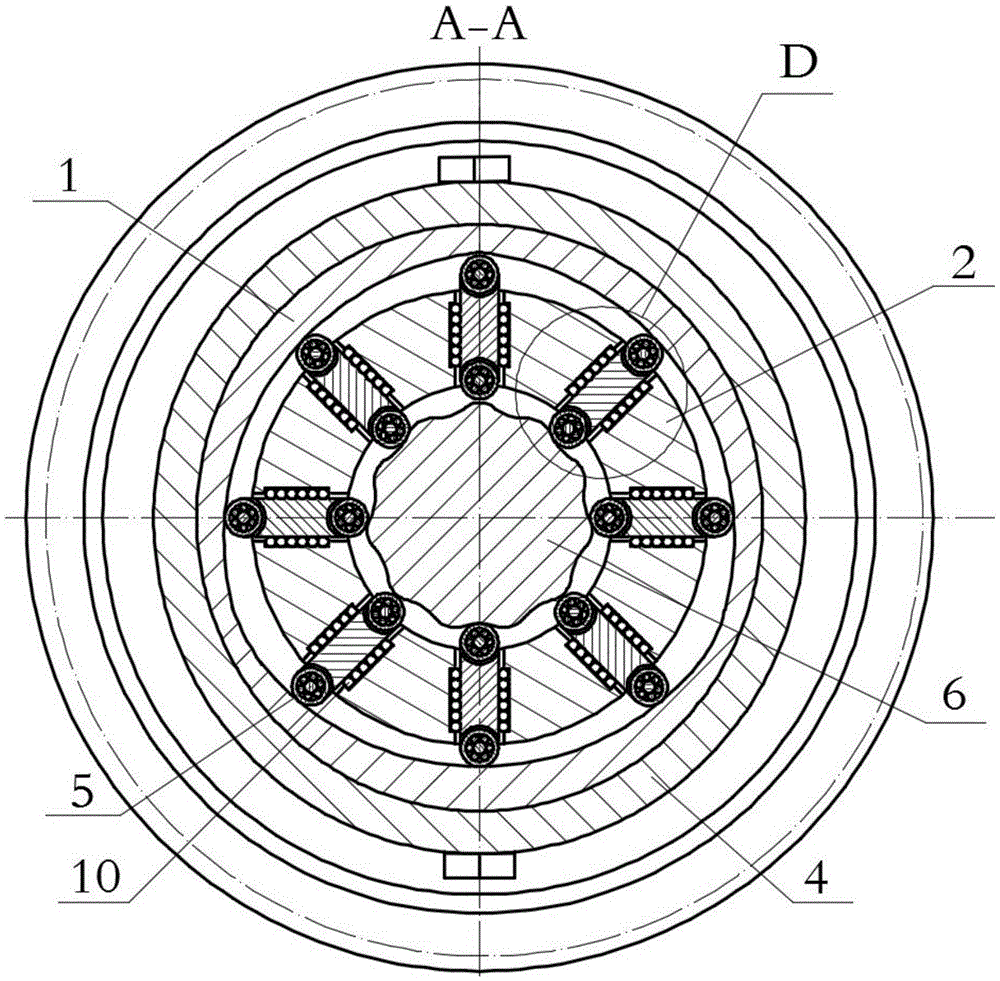

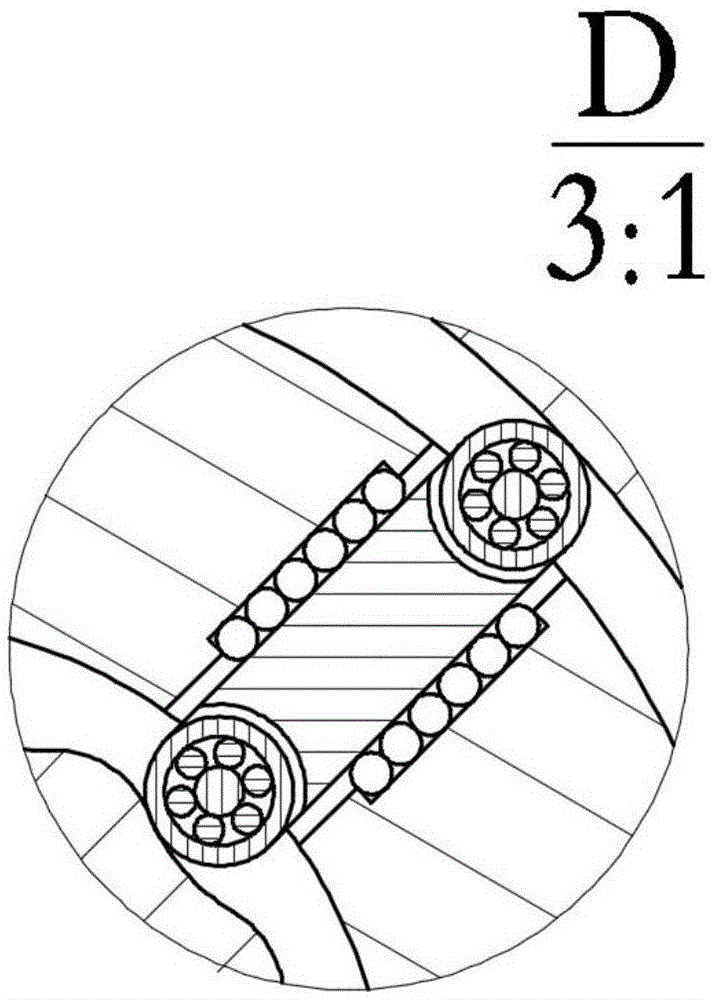

[0037] Figure 1 to Figure 8 The shown arbitrary tooth difference internal cam shock wave needle roller block type automotive differential is mainly composed of external gear internal multi-phase internal cam (1), left side axle frame (2), tapered roller bearing (3), right Half shell (4), needle roller block (5), center wheel of right half shaft (6), deep groove ball bearing (7), screw (8), deep groove ball bearing (9), needle roller (10) , a sleeve gasket (12), and a deep groove ball bearing (13). Sub-block - center wheel" system, the system mainly includes multi-phase inner cam (1), left half shaft frame (2), needle roller block (5), right half shaft center wheel (6), This system realizes the differential speed and constitutes the differential gear; the external gear internal multi-phase internal cam (1) is a straight-toothed bevel gear on the outside, and the internal is a multi-phase internal cam, that is, the internal has three mutually forming an included angle of 120 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com